The dust test machine, also known as the dust test machine, is used to simulate dry and dusty environments, test the dust-proof performance of products, and evaluate their reliability and durability in harsh conditions such as deserts and Gobi.

The dust test machine complies with international standards such as IEC 60529, MIL-STD-810H, and ISO 20653, and is widely used in the IP protection level testing in fields such as automotive parts, military equipment, outdoor electronics, and electrical enclosures.

It has been simulating harsh dusty environments for a long time. For the dust test machine, only by doing a good job in daily maintenance and care can it maintain a high-performance state to simulate the harsh test environment, and at the same time improve the accuracy of the dust test and extend the service life of the equipment.

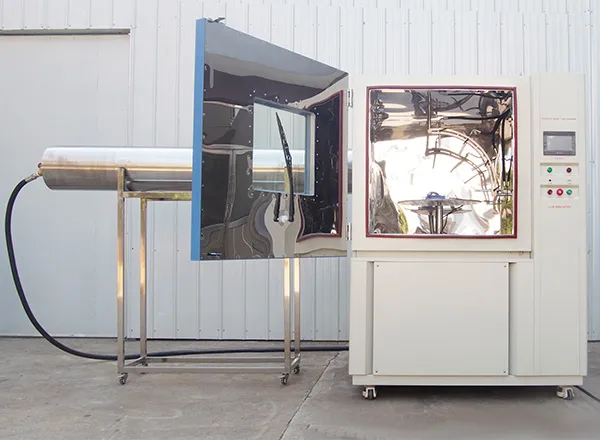

The LIB dust test machine is advanced in design and rigorous in structure. It can support IP5X and IP6X grade tests. It is equipped with an internal dust circulation system, and the tests can be programmed and carried out automatically, supporting long-term operation.

Main technical parameters:

Model | DI-800,DI-1000,DI-1500,DI-2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

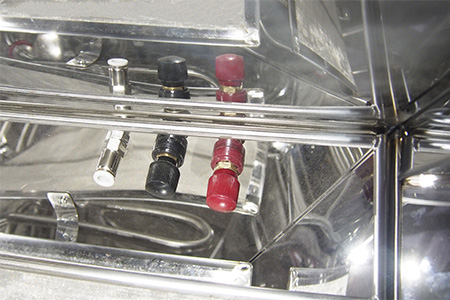

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

| |

Good daily maintenance is the foundation for ensuring the long-term operation of the dust test machine and the accuracy of the data. Regular inspections, standardized cleaning procedures, the use of original factory parts and dust will significantly reduce the failure rate and maintenance costs.

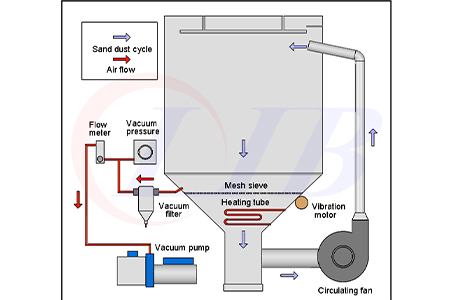

1.Clean the dust recovery and filtration system

After each test, be sure to clean the dust filter and collector to avoid blockage.

Use a clean compressed air gun to clean the dust in the interior of the chamber, the fan, the circulating air duct and other areas.

Pay attention to keeping it dry and avoid residual moisture in the chamber to prevent dust from caking.

2. Check the sealing system

Check whether there is any dust leakage in the sealing strips of the chamber door and the sealing parts of the cable holes.

Wipe the silicone sealing strip regularly with a dry cloth to keep it soft and in good fit.

The sealing strip is recommended to be replaced every 12 to 18 months, depending on the frequency of use.

3. Verify the accuracy of the test system

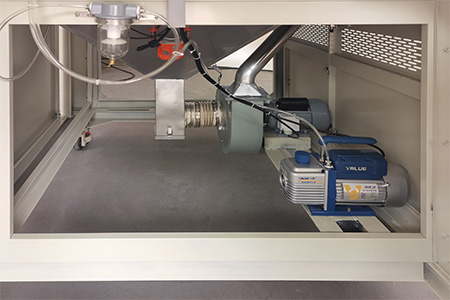

Check whether the vacuum system operates stably, especially whether the negative pressure system is normal during the IP6X test.

Calibrate key components such as sensors and timers every 3 to 6 months;

4. Add and replace the test dust correctly

Use standard-compliant test dust, such as talcum powder or Arizona sand;

It is recommended to replace the dust with new dust every 3 to 5 tests, or decide based on the degree of dust deterioration.

Do not reuse dust that has become damp or has undergone particle changes.

5. Lubricate and inspect moving parts

Regularly check whether the fan, motor, vibrator and air pump are operating smoothly.

Check whether the electrical wiring and grounding are secure to prevent static interference.

Choose the LIB dust test machine now and get professional, accurate and compliant dust-proof testing support! Contact us at inquiry@libtestchamber.com. Welcome to consult about dust test machine customization and maintenance plan!

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia