Xenon arc test Instruments are pivotal in material science for evaluating the weatherability and lightfastness of products. By simulating the full spectrum of sunlight, along with controlled temperature, humidity, and rain, these xenon arc test Instrument https://www.libtest.com/products/xenon-arc-chamber/ accelerate the aging process.

This article delves into the core technology, performance limits, and innovative design features that define high-performance xenon testing, with a focus on solutions from LIB.

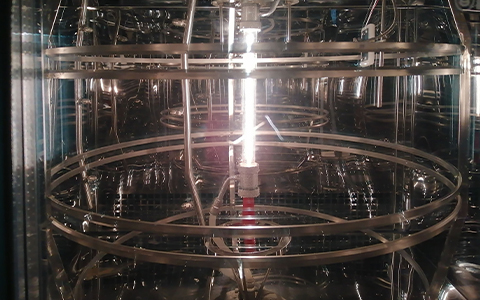

A xenon arc lamp is a gas discharge lamp. An electric arc passes through high-pressure xenon gas inside a sealed quartz tube, creating a broad-spectrum light that closely mimics natural sunlight.

The raw light is too intense in certain wavelengths. LIB chambers use specialized outer glass filters—cooled by circulating water—to precisely tailor the output to the exact solar spectrum required for testing, typically 280nm to 800nm.

Accurate simulation of UV, visible, and infrared light (including the thermal effects of 760-800nm IR) is essential for predicting real-world material failure.

A dedicated uniformity system ensures consistent temperature and humidity, even with a partially filled chamber.

The rotating sample tray turns at up to 7 RPM to guarantee even exposure for all samples.

While standard models operate above ambient, LIB engineers chambers capable of reaching extreme lows of -50°C. Achieving this requires an integrated design approach: specialized lamps rated for extreme temperatures, increased compressor power, and custom low-temperature components like diaphragm valves and sensors.

Precise stability at key wavelengths (e.g., 340nm or 420nm).

Typical setpoint: 0.5 W/m² with a tight tolerance of ±5%.

A dedicated uniformity system ensures consistent temperature and humidity, even with a partially filled chamber.

The rotating sample tray turns at up to 7 RPM to guarantee even exposure for all samples.

Thermal management is critical for stability, lamp life, and operational comfort.

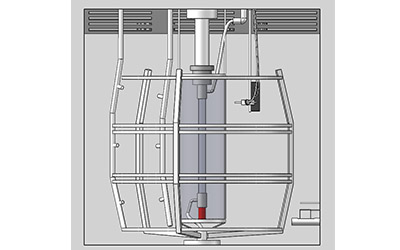

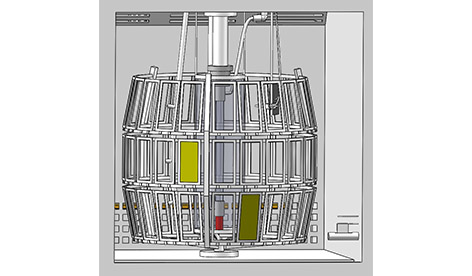

Superior Water-Cooling: Unlike noisy air-cooled systems, LIB champions water-cooled lamp technology. This signature approach significantly reduces operational noise and provides vastly superior heat dissipation, ensuring stable operation for extended, high-intensity testing cycles.

Tank | Function | Key Features | |

Main Tank | Lamp cooling & humidification | LIB's innovation: Integrated compressor-based refrigeration. Auto-fill, filtration, and level alerts. |  |

Spray Tank | Rain simulation | Manual fill. Optional heater for precise water temperature control. |  |

Flexibility and safety are integral to meeting diverse testing protocols.

Standard Rack: ~650mm diameter, holds 42 samples (up to 30mm thick).

Lamp-to-Sample Distance: Internationally standardized 375mm.

Customization: LIB can build racks for samples up to 110mm thick.

BPT (Black Panel Temperature): Metal panel, measures surface temperature.

BST (Black Standard Temperature): Insulated plastic panel.

BST > BPT: The insulated BST provides a more accurate reading for the surface temperature of non-conductive materials.

Electromagnetic Lock: Prevents accidental door opening during tests.

Standardized 13mm (OD) fittings for inlet and outlet.

Inlet solenoid valve prevents backflow for added safety.

Conclusion

A modern xenon arc instrument is a synergy of optical, thermal, and control engineering. From precise spectral matching and extreme temperature performance to innovative, quiet cooling and flexible sample handling, every design decision impacts the reliability of test data. LIB's approach, emphasizing proprietary cooling architecture, rigorous control, and robust safety features, provides the advanced technology necessary to trust the durability of your materials in any environment.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia