Paints and coatings are designed not only for aesthetics but also to protect underlying materials against environmental stress. However, prolonged outdoor exposure to sunlight, rain, and humidity inevitably causes fading, chalking, cracking, and delamination. To predict these failures before products reach the market, manufacturers rely on UV aging machines —laboratory equipment that accelerates weathering under controlled conditions.

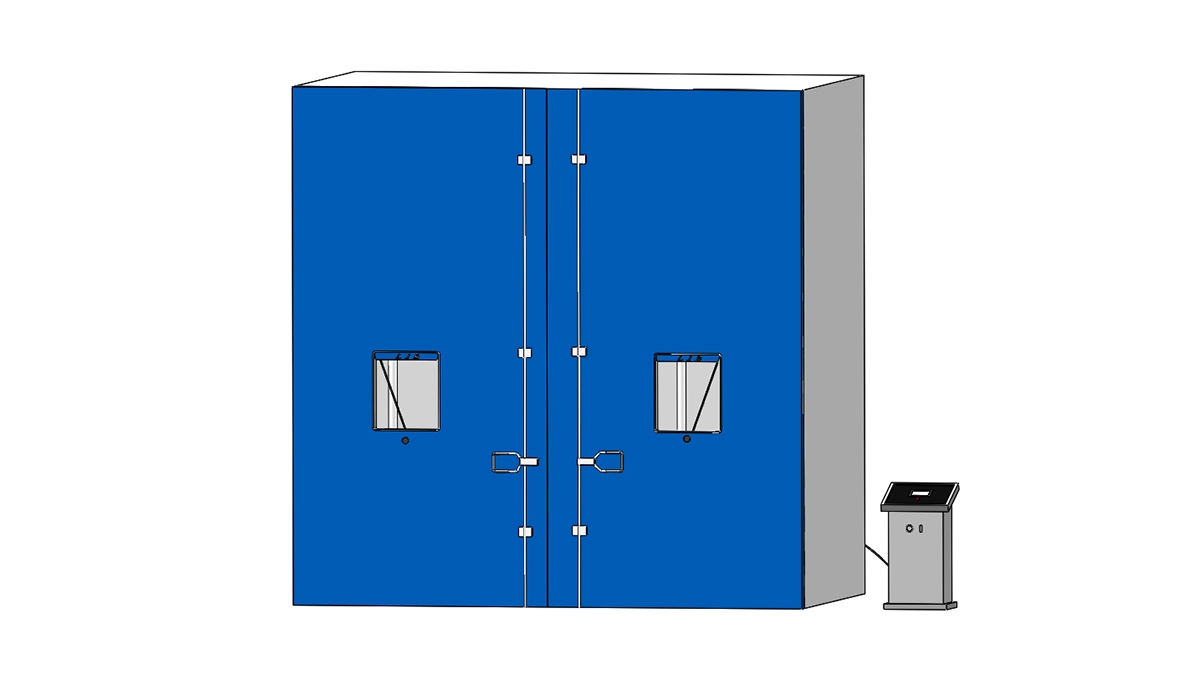

Among the leading solutions in this field, the LIB UV aging machines (UV-SI-260) is engineered to simulate years of sunlight and moisture exposure in just weeks, providing accurate and repeatable results for coatings and paints.

The UV spectrum of sunlight is the main driver of paint and coating degradation. UV radiation breaks polymer bonds in resins and pigments, reducing color stability and mechanical strength. When combined with heat and moisture, this process is even faster, leading to early product failure if not properly addressed.

UV aging testing provides three critical benefits for coating manufacturers:

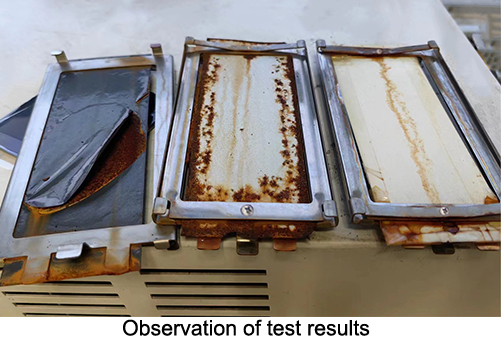

Accelerated lifetime prediction – simulating years of outdoor weathering in a laboratory cycle.

Comparative material evaluation – testing different formulations side by side under identical stress.

Standard compliance – meeting international requirements such as ASTM G154, ISO 4892-3, and SAE J2020.

A typical UV aging test for coatings and paints follows these steps:

Define exposure cycles according to ASTM or ISO methods.

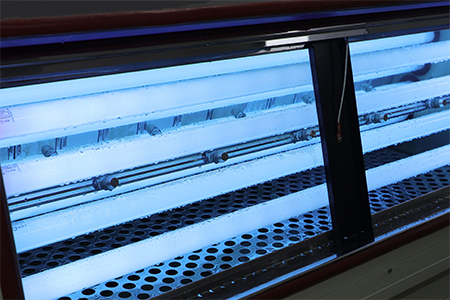

Select appropriate lamps (UVA-340 for sunlight simulation or UVB-313 for accelerated testing).

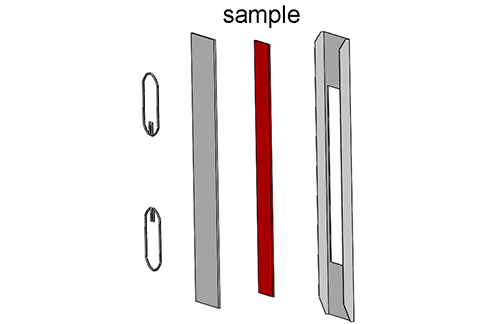

Paint panels are cut to standard size (75 × 150 mm).

Up to 56 samples are placed on holders, positioned evenly 50 mm from the lamps.

Standard test pieces are prepared and installed on the sample holder.

UV irradiance adjustable between 0.3–20 W/m².

Black panel temperature set between 35–80 °C, chamber temperature up to 90 °C.

Relative humidity maintained above 95% RH during condensation cycles.

The LIB UV chamber integrates 10 spray nozzles for controlled water spray, simulating rain impact and morning dew.

The touchscreen controller allows programming of light/dark cycles, temperature, humidity, and spray intervals.

Real-time monitoring displays UV lamp status and irradiance to ensure consistent exposure.

After a defined test period (e.g., 500–1000 hours), samples are inspected for fading, gloss loss, chalking, or cracking and compared against control panels.

The LIB UV-SI-260 incorporates multiple design features tailored for coatings and paints durability testing, and it fully aligned with ASTM, ISO, and SAE requirements, with CE and RoHS certifications.

Key Advantage | Why It Matters | Details Display |

Flexible UV Light Sources | Supports UVA-340 & UVB-313 lamps for precise spectral simulation—ideal for coatings and paints durability testing. |  |

Comprehensive Test Parameters | Irradiance: 0.3–20 W/m² | |

High Durability Construction | SUS304 stainless steel interior + anti-corrosion exterior ensures long-lasting reliability. |  |

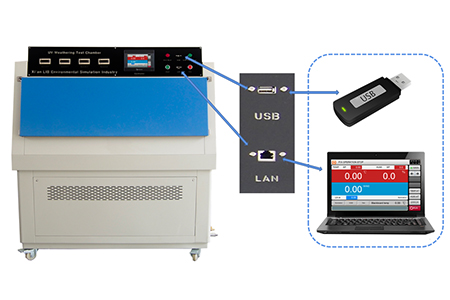

Advanced Control System | Color LCD touchscreen, Ethernet/USB connectivity, program storage, and remote monitoring for efficient testing. |  |

User Convenience | Mobile casters, easy lamp replacement, and intuitive interface for quick, hassle-free operation. |  |

LIB UV aging machines are widely applied across industries where paint and coating reliability is critical:

Automotive paints – validating resistance to gloss loss, fading, and micro-cracking on car bodies.

Architectural coatings – testing exterior paints for long-term color stability and anti-chalk performance.

Industrial protective coatings – ensuring anti-corrosion coatings maintain adhesion and durability in UV-intensive environments.

Consumer goods finishes – verifying decorative coatings on plastics, metals, and wood against early discoloration.

Unlike generic UV test equipment, LIB UV aging machines combines precise UV control, robust construction, and ease of operation, making it ideal for coating manufacturers seeking reliable accelerated weathering tests. With a three-year warranty and lifetime service support, LIB ensures long-term value and confidence for your testing lab.

Looking to strengthen your coatings durability testing? Choose LIB UV aging machines inquiry@libtestchamber.com —your partner in advanced weathering solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia