Freeze Thaw Chamber Features and Benefits

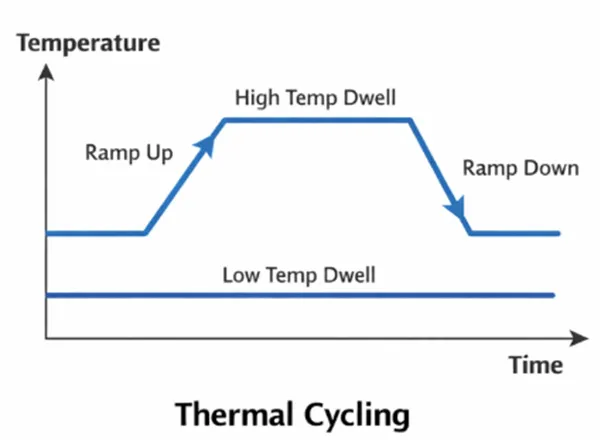

1.The temperature range is from -20℃ to +100℃, from severe cold to high temperature. It supports rapid switching between freezing and heating states, meeting the cycle frequency requirements in the standard and adapting to the testing needs of various materials and products.

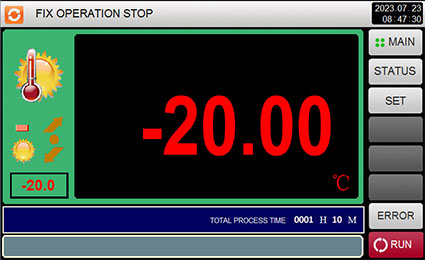

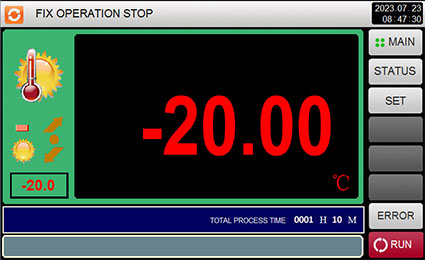

2. Programmable controller (PLC or touch screen control system), which can set multiple freeze-thaw cycles (for example, 50 to 300 times). Automatically record the data of each cycle.

3. High-precision temperature control with small internal temperature fluctuations (temperature uniformity: ±2℃, temperature fluctuation: ±0.5℃) ensures the repeatability and comparability of test results.

4. Meet the freeze-thaw cycle test requirements in multiple international standards such as ASTM C666, ASTM D714, and ISO 9142.

Freeze Thaw Chamber Specifications

Model | T-100 | T-225 | T-500 | T-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Safety Device | Over-temperature protection; Over-current protection; Refrigerant high-pressure protection; Earth leakage protection |

Details of Hot Cold Chamber

|

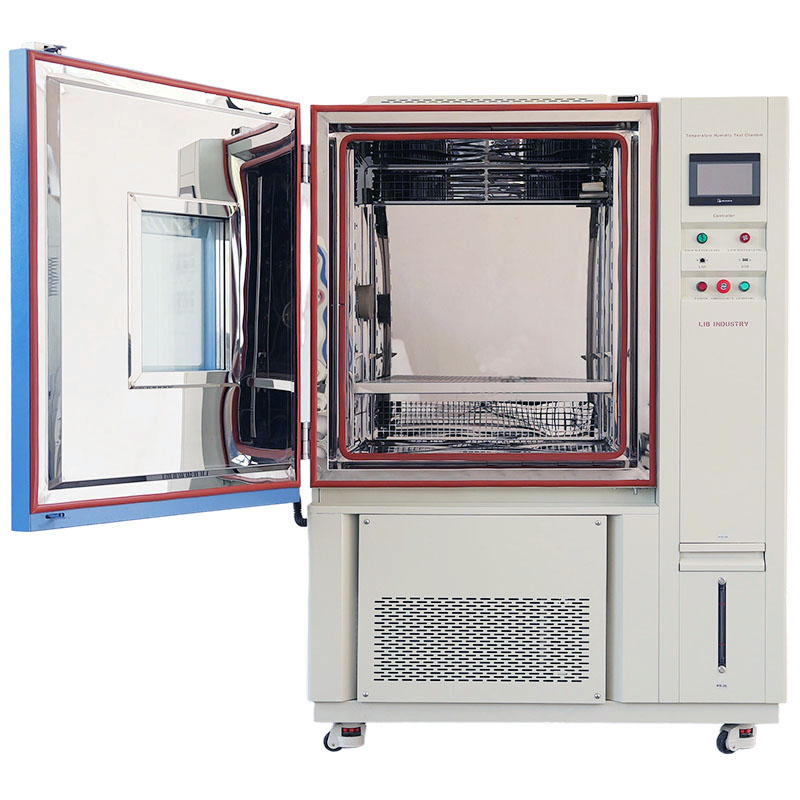

Workroom | Program controller |

SUS304 , anti-corrosion; Double-layer shelf design (customizable number of sample racks), standard load-bearing capacity 50KG, with internal lighting. The effective volume ranges from 100L to over 1000L, supporting the testing of medium and large samples as well as multi-batch testing.

| The color touch screen controller can preset multiple sets of freezing/thawing cycle programs (such as: maintaining at -20℃ for 2 hours, maintaining at +50℃ for 2 hours per cycle, and repeating 100 times). Supports USB data export and remote monitoring functions.

|

|  |

Refrigeration system | Precise temperature sensor |

French Tecumseh compressors, featuring stable performance, low noise, mechanical refrigeration and environmentally friendly refrigerants. | The PT100 temperature sensor, with a control accuracy as high as ±0.1℃, can monitor the temperature inside the box in real time and achieve rapid feedback and adjustment of the temperature control system. |

|  |

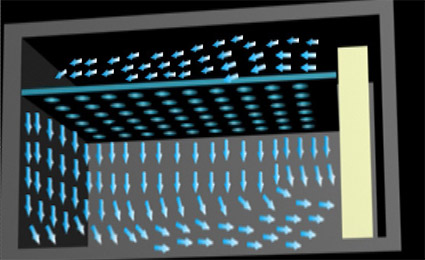

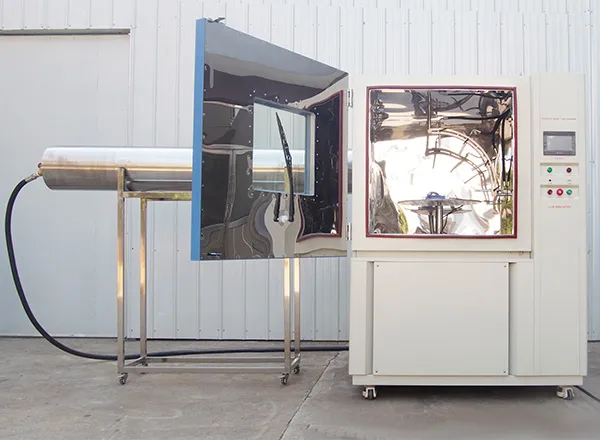

Observation window | Air circulation system |

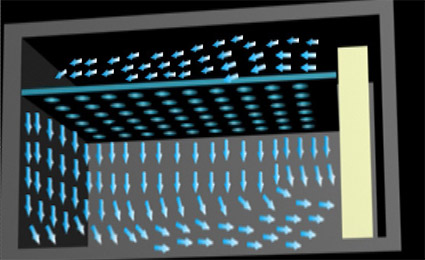

Hollow explosion-proof tempered glass, which has excellent heat insulation and anti-frosting capabilities. Conductive film is added to the middle layer to enhance the insulation performance. | High-power low-temperature resistant axial flow fans can evenly distribute air flow in both cooling and heating states. Achieve rapid response and uniform diffusion of temperature within the workroom. |

|  |

LIB offers technical support covering the entire life cycle of freeze thaw chamber usage (including installation guidance, operation training, fault diagnosis and spare parts support), a 3-year warranty and lifetime service. If you need to know more, please feel free to leave a message.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia