Features and Benefits of Dust Exposure Test Equipment

1. Complies with multiple international testing standards such as IEC 60529(IP5X/IP6X), ISO 20653, and SAE J575. It can also meet the more stringent sand and dust test requirements of industries such as automobiles and military industry.

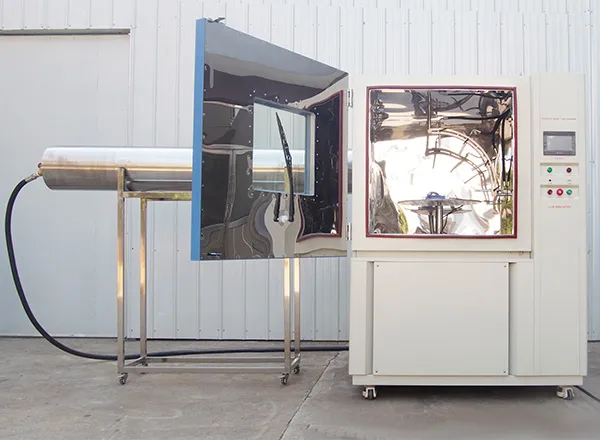

2. LIB can customize large-capacity models like walk-in dust exposure test equipment according to customer requirements to meet the testing needs of large samples such as complete vehicles and communication cabinets.

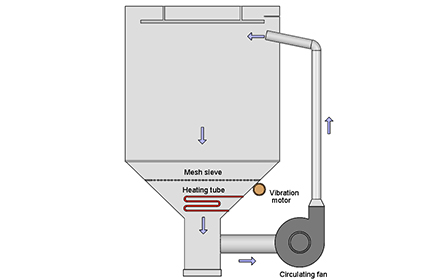

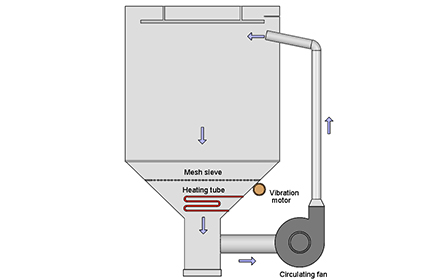

3. The centrifugal fan and the air diversion structure precisely regulate the internal airflow. At the same time, combined with the dust recirculation technology, it ensures the uniform distribution of dust.

4. Multiple standard models such as DI-800, DI-1000, DI-1500, DI-2000, etc. can be delivered quickly and comply with international certifications such as CE and ISO.

Specifications of Dust Exposure Test Equipment

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

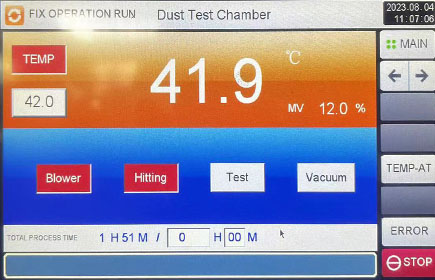

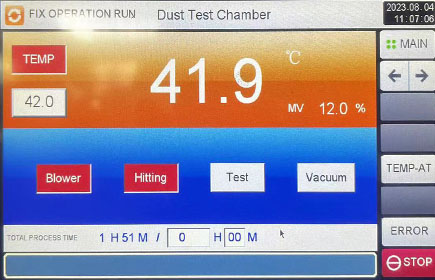

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Earth Leakage Protection; Phase Sequence Protection |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

Power | AC380V 50Hz |

Details of Dust Exposure Test Equipment

|

Workroom | Dust Circulation System |

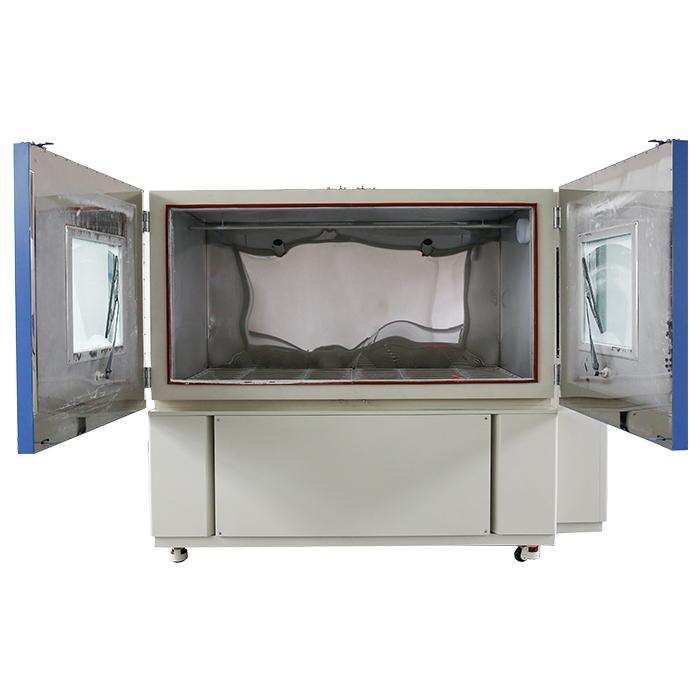

SUS304 stainless steel, with excellent corrosion resistance and cleanliness. It is equipped with sample racks (suspended type, grid plate type) inside, suitable for different testing products. The sealing strip ensures that the dust does not leak out, and it is equipped with an observation window and lighting.

| Dust is drawn from the funnel area at the bottom to the upper part of workroom by a centrifugal fan, achieving a closed-loop circulation. The dust is evenly diffused and continuously suspended, ensuring consistent test coverage. Dust can be recycled and reused.

|

|  |

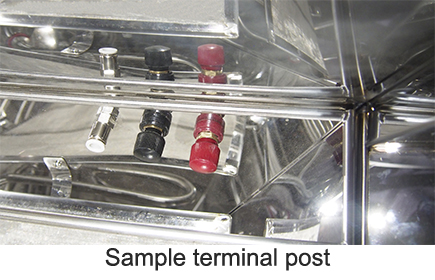

Vacuum Pump | Heating Element |

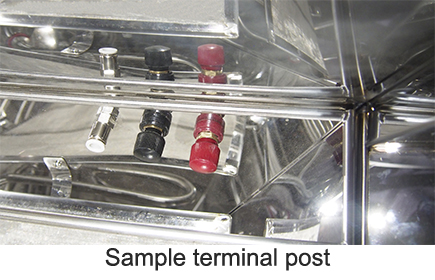

Integrated with a high-performance vacuum pump and connected to DUT through a sealed interface. When used for the IP6X negative pressure dust-proof test, form a pressure difference of less than 2KPA inside the sample, effectively detecting the sealing performance of the casing.

| To prevent dust from clumping due to moisture, the air temperature can be raised from RT to 50 ℃ to ensure that the dust remains in a dry and flowable state. |

|  |

Dust Filter Screen | Intelligent touch PLC controller |

Ensure that the particle size meets the standard requirements (e.g., talcum powder less than 75μm). Prevents large particles or impurities from entering the circulation system, thereby ensuring the consistency of the test and the stability of the equipment.

| With multiple languages to choose from, is simple and intuitive to operate. It can precisely set parameters such as time, wind speed, cycle, vacuum pumping and heating temperature, and provides real-time data monitoring and historical recording. PC remote control and data export.

|

|  |

If you have any other customization requirements for the dust exposure test equipment, please feel free to leave your requirements. The LB team will contact you promptly. All LIB products enjoy a 3-year extended warranty and lifetime service.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia