What Are UL1332 and UL2431 Tests?

UL1332 – Coating Corrosion Resistance

Tests outdoor steel enclosure coatings under high humidity (~95% RH), elevated temperature (~40 °C), SO₂/CO₂ gas, and optional salt spray. Monitors blistering, peeling, cracking, and corrosion over hundreds to ~1000 hours.

UL2431 – Material Durability

Evaluates long-term performance of materials and coatings with humidity/temperature cycling, corrosive gas exposure, and extended continuous testing, ensuring structural integrity and protective performance.

LIB industry Solution

Our SO₂ & CO₂ Gas Corrosion Durability Test Equipment fully supports both UL1332 and UL2431 methods with:

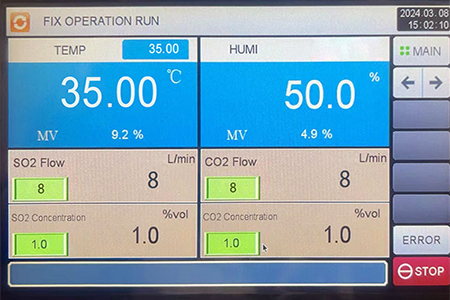

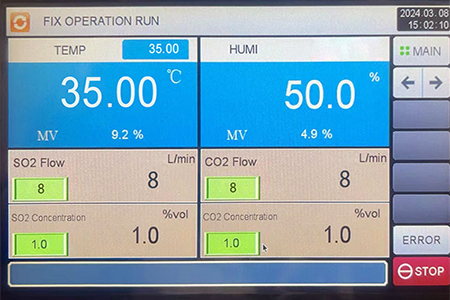

Precise SO₂ / CO₂ gas control

Stable high-humidity and temperature conditions

Long-term continuous operation

Customizable programmable test sequences

With a single system, you can perform UL1332 coating corrosion tests + UL2431 material durability validation, while also generating reliable data for UL50E enclosure protection assessments.

UL1332 UL2431 SO2 CO2 Gas Corrosion Durability Test Equipment Features and Benefits

1. Precise and Stable Environmental Control –

The chamber provides highly accurate regulation of SO₂ and CO₂ gas concentrations, temperature, and humidity, maintaining consistent test conditions throughout long-duration experiments. This ensures that every corrosion durability test meets UL2431 requirements and delivers reliable, repeatable results.

2. Long-Term Durability Testing

Designed for continuous operation from hundreds up to 1000 hours, the allows thorough evaluation of coatings, materials, and substrates under harsh corrosive conditions. It effectively reveals blistering, peeling, cracking, or corrosion propagation, helping engineers optimize material formulations and verify product longevity.

3. Corrosion-Resistant and Robust Construction

Built with SUS316 stainless steel interior and reinforced insulated exterior, the gas corrosion chamber resists chemical attack while providing structural stability. The durable construction ensures minimal maintenance, long service life, and reliable performance even in demanding industrial environments.

4. Flexible Programmable Operation

Equipped with a 7-inch PID touchscreen, the system supports up to 120 programmable test sequences with 100 segments each, including multi-stage temperature, humidity, and gas exposure. Users can easily customize testing cycles for various materials or coatings, streamlining research, quality control, and certification workflows.

Specifications of UL1332 UL2431 SO2 CO2 Gas Corrosion Durability Test Equipment

Model | GCM-500 |

Internal Dimensions | 900*800*700 (mm) D*W*H |

Overall Dimensions | 1600*1350*1850 (mm) D*W*H |

Interior Volume | 500(L) |

Parameter | Temperature Range | 15 ℃ ~ 80 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity | Display |

SO2 concentration | 1% of volume of test chamber |

CO2 concentration | 1% of volume of test chamber |

Air Change | Automatic control |

Structure | Cooling | Cooling system | Mechanical compression refrigeration system,French TECUMSEH compressor |

Refrigerant | R404A |

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller,Ethernet connection, PC Link |

Sensor | Temp Sensor | PT100Ω / MV A-class |

Humidity Sensor | Dry and wet bulb sensor |

Gas Sensor | SO2 gas sensor and CO2 gas sensor |

Build-in Water Tank(mm) | 900*800*100mm |

View Window Size(mm) | 330*370 |

Air Circulation | Centrifugal wind fan |

Door Lock | Electromagnetic lock |

Gas Exhaust Device | Gas Exhaust Unit |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Interior material | SUS316 stainless steel |

Exterior material | Steel Plate with protective coating |

Power Supply | 220V 60Hz 1 phase |

Maximum Noise | 65 dBA |

Standard | UL 2431 |

Environmental Conditional | 5℃~+35 ℃ ≤85% RH |

Details of UL1332 UL2431 SO2 CO2 Gas Corrosion Durability Test Equipment

|

|

Workspace SUS316 stainless steel workroom, providing superior corrosion resistance and durability. 2 adjustable punched sample racks accommodate multiple test specimens up to 50 kg per layer. The LED-illuminated, double-glass observation window allows clear monitoring without opening the chamber.

| Exhaust and Gas Treatment System The waste gas system safely neutralizes SO₂ and CO₂ emissions using a NaOH solution absorption tank. Gas inlet is precisely controlled via electromagnetic valves, and the chamber automatically vents treated gas after testing, ensuring operator safety and environmental compliance.

|

|

|

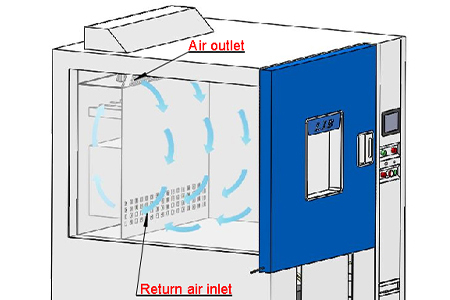

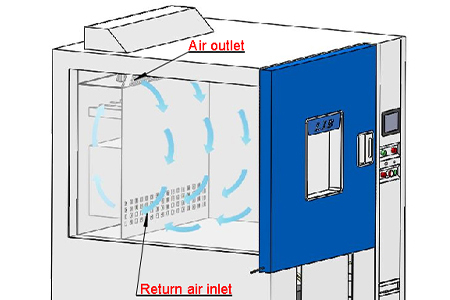

Air Circulation System High-efficiency centrifugal fan, the system provides top-to-bottom air circulation for uniform temperature and humidity distribution. This ensures consistent test conditions across all sample locations. | Control System A 7-inch PID programmable touchscreen allows full control of temperature, humidity, and gas concentrations. The system supports fixed and programmable operation modes, data logging via USB or Ethernet, and multilingual interface options, enabling precise, repeatable, and user-friendly testing.

|

Get in touch with LIB industry inquiry@libtestchamber.com to customize your SO₂/CO₂ durability testing solution.Backed by customized configurations, on-site installation, operator training, 3-year warranty, lifetime support, and fast English-speaking service. Contact LIB industry today for a tailored corrosion testing solution.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia