Water exposure remains one of the most critical factors affecting the performance and reliability of electronics, automotive components, and industrial devices. Even brief contact with water can cause failures, corrosion, or safety hazards. To address these risks, LIB Industry’s IPX5 IPX6 Water Test Equipment provides precise, repeatable high-pressure spray testing according to IEC 60529 standards, ensuring accurate assessment of product waterproof performance. The system’s core, the IPX5 X6 water spray jetting chamber, simulates real-world water exposure conditions, from light rain to high-pressure jets, with consistent, programmable parameters.

|

|

The IPX5 rating guarantees protection against water jets from any direction, while IPX6 ensures devices can withstand high-pressure, heavy water jets. Testing for these standards is essential for products such as:

· Automotive sensors and connectors exposed to rain or high-pressure cleaning

· Consumer electronics like smartphones, wearable devices, and outdoor equipment

· Industrial control systems in wet or humid environments

The IPX5 X6 water spray jetting chamber ensures each product is exposed to repeatable, precise spray conditions, allowing manufacturers to confidently meet IEC certification requirements.

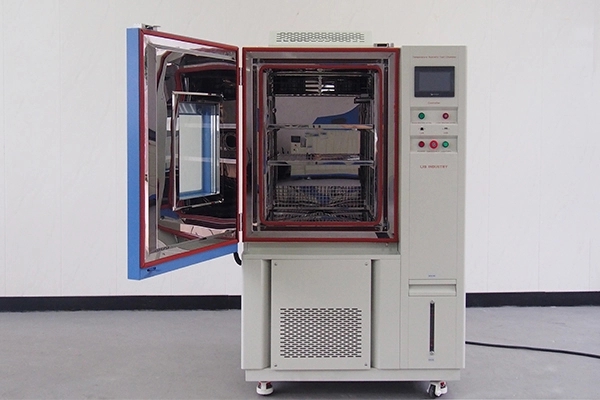

The system is engineered for accuracy, reliability, and ease of use, combining robust mechanical design with advanced control technologies:

· Precision nozzles: Stainless steel nozzles deliver uniform spray coverage. IPX5 uses flat spray nozzles, while IPX6 employs high-pressure jets.

· Programmable digital controller: Allows automated sequences, adjusting spray duration, angle, and pressure.

· Adjustable spray angles and distances: 0–360° rotation and 2.5–3 meters distance accommodate various product sizes.

· Durable materials: Stainless steel SUS304 interior ensures corrosion resistance; exterior is coated steel for durability.

· Safety systems: Over-temperature, over-current, water shortage, earth leakage, and phase sequence protection ensure operator and equipment safety.

· Customizable dimensions: Designed to handle small electronics as well as large automotive or industrial components.

|  |

IPX5 X6 Independent Nozzles | Programmable Digital Controller |

|

|

SUS 304 Workroom | Waterproof Power Supply |

These features allow engineers to conduct precise, repeatable, and IEC-compliant testing with minimal setup effort.

| |

Name | IPX5 IPX6 Water Test Equipment |

Model | R56-800 |

Workroom dimension (mm) | 800*800*800 |

External dimension (mm) | 950*3150*1800 |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3mm |

Internal Diameter of IPX6 Nozzle | 12.5mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Water tank, booster pump, Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Double layer insulating glass with wiper |

The IEC 60529 standard defines protection ratings against water and solid particles. The IPX5 IPX6 Water Test Equipment ensures strict compliance:

· IPX5: Water jets at 12.5 L/min and 30–100 kPa, sprayed from any direction for 3–10 minutes.

· IPX6: High-pressure jets at 100 L/min and 100–150 kPa, with the same duration, simulating extreme rain and wash conditions.

Key principles of testing include:

1. Nozzle uniformity: Ensures consistent water exposure across the entire product surface.

2. Stable pressure control: Pumps and valves maintain precise flow rates.

3. Adjustable spray angles: Full 360° coverage prevents untested surfaces.

4. Digital automation: Programmable sequences improve reproducibility and reduce human error.

By following these principles, LIB Industry guarantees high repeatability and IEC compliance for both IPX5 and IPX6 certification.

Beyond IPX5 and IPX6, LIB Industry provides comprehensive solutions for IPX1–IPX9K, JIS D0203, MIL-STD 810, and GMW 16001 standards. This allows a single system to meet multiple waterproofing requirements:

IPX1–IPX4: Drip or splash testing with 1–10 L/min low-pressure water;

IPX5–IPX6: Water jet testing with 12.5–100 L/min flow and 30–150 kPa pressure;

IPX7–IPX8: Immersion testing at 1–3 m depth for 30–60 minutes;

IPX9K: High-pressure and high-temperature spray testing at 80–100 bar and 80°C; for automotive and heavy equipment.

JIS D0203 / MIL-STD 810 / GMW 16001/UL 50E: Rain and water jet testing according to standard specifications; applied in automotive, military, and industrial environments.

LIB Industry Waterproof Test Equipment | |

| IPX1 IPX2 IPX3 IPX4 Rain Test Machine IPX7 IPX8 Water Immersion Test Equipment UL 50ESprinkler Rain Test Apparatus

|

Such versatility ensures that engineers can handle all waterproof testing requirements with a single supplier, streamlining workflow and reducing equipment investment.

LIB Industry IPX5 IPX6 Water Test Equipment is widely applied in:

· Automotive components: Sensors, connectors, and modules are exposed to simulated rain, high-pressure washes, and environmental extremes.

· Consumer electronics: Smartphones, wearables, and outdoor devices are validated for real-world waterproof performance.

· Industrial devices: Controllers and electrical components are tested for reliability under wet or humid conditions.

Performance analysis demonstrates that products tested with R56-800 consistently meet IEC standards while reducing variability and improving operational efficiency.

Q1: Can LIB Industry customize equipment for unique products?

A1: Yes. Nozzle layouts, chamber dimensions, and spray angles can be tailored for specific testing needs.

Q2: What warranty and service are provided?

A2: All equipment comes with a 3-year warranty, 1~ 3hours rapid-response technical support, and preventive maintenance.

Q3: Are other waterproof standards supported?

A3: Yes. LIB Industry covers IPX1–IPX9K, JIS, MIL-STD, and GMW standards, including high-pressure rain and water spray simulations.

Q4: How is testing accuracy ensured?

A4: High-quality pumps, precision nozzles, and digital programmable controllers guarantee repeatable, IEC-compliant results.

For engineers, OEMs, and test laboratories, LIB Industry’s IPX5 IPX6 Water Test Equipment High Pressure Spray Testing According to IEC Standards provides precise, repeatable, and versatile testing solutions. Using the IPX5 X6 water spray jetting chamber, manufacturers can confidently validate product waterproof performance and achieve IEC certification.

Contact LIB Industry today inquiry@libtestchamber.com for a consultation or equipment demonstration, and ensure your products meet the highest waterproof standards.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia