Electrical equipment is only as safe as the enclosure that protects it. Rain, humidity, and high-pressure water jets can all threaten sensitive electronics if the housing is not properly designed. To verify durability and compliance, manufacturers rely on UL 50E electrical equipment enclosure testing.

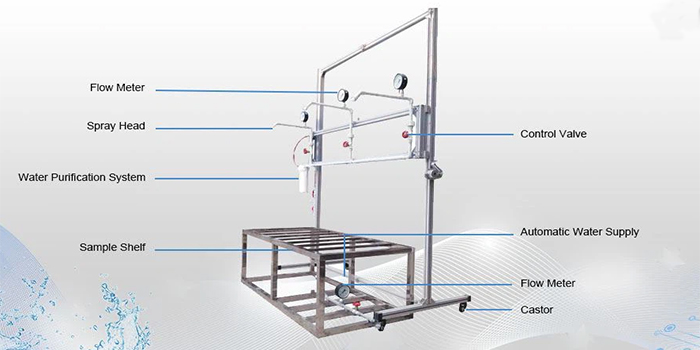

LIB Industry provides a purpose-built solution: the UL 50E Shower , engineered for precise and repeatable testing. With it, manufacturers can confidently evaluate the integrity of junction boxes, control cabinets, outdoor telecom housings, and other enclosures under simulated real-world water exposure.

An enclosure serves as the first barrier against environmental hazards. UL 50E testing evaluates whether:

· Water penetrates into the housing under simulated rain or spray conditions.

· Gaskets, seals, and joints can resist long-term exposure.

· The enclosure maintains functionality and safety even in harsh weather.

Without this verification, enclosures risk leakage, short circuits, and premature failures, leading to costly recalls and damaged reputations.

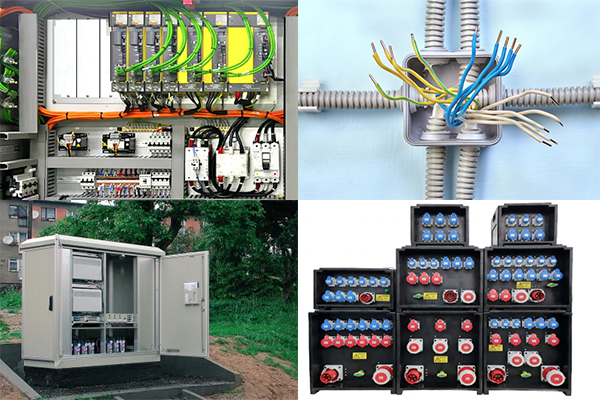

LIB’s UL 50E Shower is designed to handle a wide range of electrical equipment enclosures, ensuring realistic and reliable testing. Typical test specimens include:

· Industrial control panels – Metal or plastic housings protecting PLCs, relays, and power modules.

· Junction boxes – Small to medium-sized boxes used for wiring connections in industrial or building installations.

· Telecommunication cabinets – Outdoor enclosures for switches, routers, and fiber optic terminations.

· Power distribution boxes – Switchgear cabinets, transformers, and other medium-voltage enclosures.

· Consumer electronics housings – Chargers, adapters, and compact electronic devices requiring water resistance.

· Outdoor sensor enclosures – Housings for environmental sensors, smart meters, or IoT devices.

Each specimen is securely mounted inside the UL 50E Shower and subjected to controlled water spray conditions. This ensures every type of enclosure, regardless of size or material, meets UL 50E standards for water ingress protection.

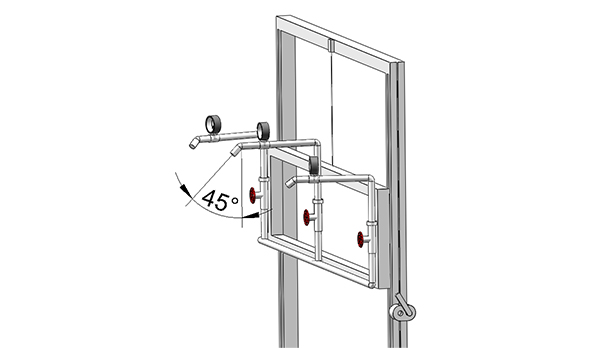

The LIB UL 50E Shower replicates the exact conditions defined in UL 50E. Testing typically involves:

1. Mounting the test specimen – The electrical equipment enclosure is positioned on a turntable or fixed stand inside the test area.

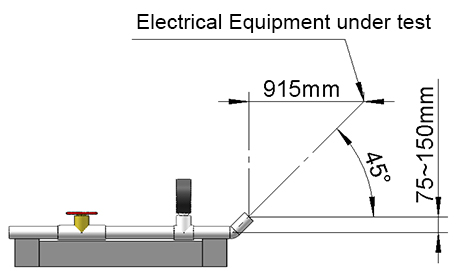

2. Controlled water spray – The shower uses multiple nozzles with an injection angle of 45°, ensuring full coverage.

3. Adjustable water pressure – Standard pressure is 34.5 KPa, with flexibility to meet different test requirements.

4. Nozzle height adjustment – Water column junctions can be set from 300–1200mm or 1000–2000mm, depending on specimen size.

5. Test duration control – Time is adjustable from 0 to 99,999.9 minutes for long-term or accelerated testing.

6. Inspection phase – After testing, the enclosure is examined for any water ingress or performance degradation.

This process ensures that every tested enclosure demonstrates its true protective capability before it reaches the market.

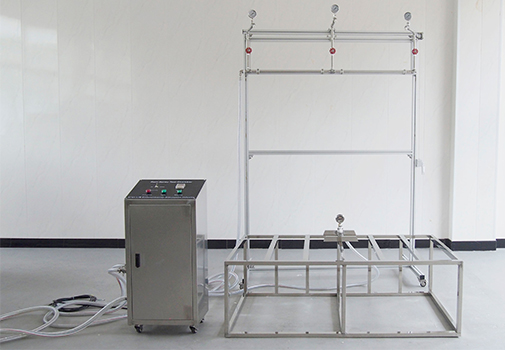

The LIB UL 50E Shower is engineered for precision and ease of use:

· UL 50E Compliance – Meets all standard requirements for water spray testing.

· Nozzle and Spray Design – Number, spacing, and structure of nozzles comply with UL standard diagrams.

· Adjustable Water Flow & Pressure – Flexible to match various enclosure sizes and test protocols.

· Robust Support Structure – Formed SUS304 stainless steel with universal belt brake casters for mobility.

· Stainless Steel Construction – Durable chamber for repeated testing cycles.

· User-Friendly Interface – Simplifies control of pressure, height, and test duration.

Parameter | Specification |

Standard Compliance | UL 50E |

Number of Nozzles | Multiple, per UL standard layout |

Injection Angle | 45° |

Water Pressure | 34.5 KPa (adjustable) |

Nozzle Height | 300–1200mm or 1000–2000mm |

Test Time | 0–99,999.9 minutes |

Support Material | SUS304 stainless steel |

Mobility | Base with universal belt brake caster |

LIB Industry doesn’t just provide testing hardware. With every UL 50E Shower, clients gain access to a robust support system:

✅ Comprehensive 3-year warranty and lifelong service covering manufacturing defects

✅ Technical training & support for test engineers

✅Spare parts & maintenance service to minimize downtime

✅ Global service network (UK,US,Canada,Malaysia) for fast assistance wherever you operate

This combination ensures that your enclosure testing process remains consistent, reliable, and worry-free.

Whether preparing new enclosures for certification or strengthening quality assurance programs, the LIB UL 50E Shower provides the precision, durability, and service support you need.Contact LIB Industry inquiry@libtestchamber.com today to discuss your testing requirements.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia