Salt spray tests, as an important means of simulating Marine, industrial and climatic corrosive environments, are widely used in fields such as metal protective coatings, electroplated parts, automotive components, and hardware accessories. The LIB salt spray test chamber has become a perennial bestseller due to its excellent equipment performance and humanized design.

The LIB salt spray chamber is equipped with a high-precision temperature control system and an automated spray system, capable of conducting various corrosion tests such as NSS, ASS, and CASS. The equipment chamber structure is sturdy and made of upgraded fiberglass reinforced plastic, featuring excellent air tightness to ensure uniform salt spray diffusion and a stable and consistent testing environment.

Model | S-150 | S-250 | S-750 | S-010 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

Temperature Range | Ambient ~ +60 ℃ | |||

Temperature Fluctuation | ± 0.5 ℃ | |||

Temperature Deviation | ± 2.0 ℃ | |||

Humidity Range | 95% ~ 98% RH | |||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||

Spray Type | Continuous / Periodic | |||

Salt Fog Collected | Fog collector and fog measure cylinder | |||

Air Preheating | Saturated air barrel | |||

Spraying System | Atomizer tower and Spray nozzles | |||

Controller | PID controller | |||

Material | Glass fiber reinforced plastics | |||

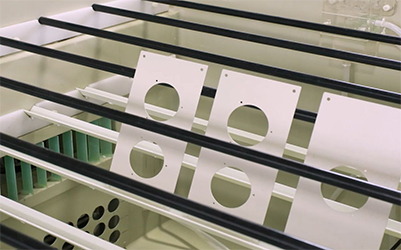

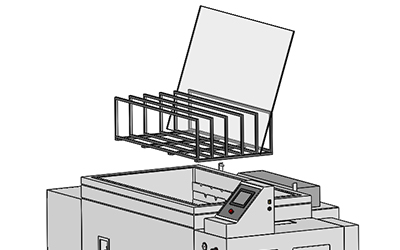

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||

The entire series is equipped with an intelligent touch screen as standard, supporting data recording, remote control and multi-stage programming, which greatly enhances the testing efficiency and operational convenience.

In practical applications, the types of test pieces that require salt spray testing are diverse, including but not limited to:

Metal sheets and coated sheets: such as automotive panels, spray-painted samples, electroplated steel plates;

Fasteners and standard parts: such as screws, bolts, rivets, washers, etc.

Special-shaped hardware: such as door lock parts, connectors, aluminum profile accessories;

Plastic parts and composite structural parts: such as ABS chrome-plated parts, electrical enclosures;

Tubular materials and bars: such as copper tubes, stainless steel bars, welded pipe fittings, etc.

Samples of different shapes and sizes have put forward different support and Angle requirements for the stand. To ensure that each test is more scientific and accurate, LIB is specially equipped with a variety of adjustable, universal and customized sample holders, and provides non-standard customization services.

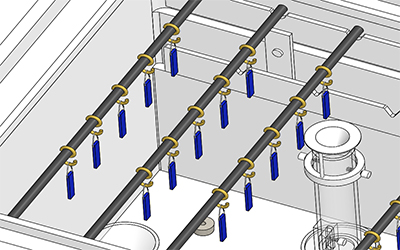

It is suitable for cylindrical samples, such as screws, pipe fittings, small shafts, etc. The V-shaped groove design can prevent rolling, and the bracket Angle is adjustable (conventional 20° to 30°), meeting the placement Angle requirements of different test standards.

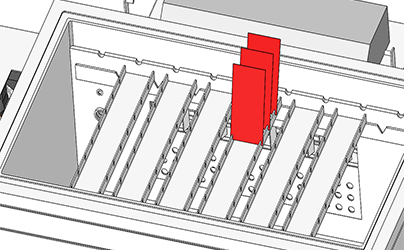

It is particularly suitable for thin plate samples, such as spray-coated plates and electroplated samples. The stand is equipped with adjustable slots, preventing samples from blocking each other and ensuring a uniform salt spray contact surface.

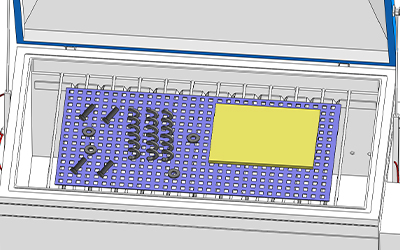

It is used for larger or bottom-supported samples, such as assembled components, structural parts, and samples that are not convenient to hang. The structure is stable and suitable for multi-size combination placement.

Designed for irregular parts, small components or perforated components. For instance, fishing lines can be used to suspend nail-like components above the test area to prevent contact corrosion from affecting the test results. Suitable for lightweight components such as plastic parts and hardware hangers.

For special products or specific test requirements, LIB offers customized non-standard support services, including adjustable mold supports, modular hanging trays, stainless steel plastic-coated hooks, etc., to ensure that the diverse and refined test demands of users in various industries are met.

Three-year whole machine warranty: All salt spray test chambers enjoy a three-year extended warranty, covering core components and accessories.

Lifetime technical support: No matter how long the equipment has been in use, LIB always provides customers with free technical consultation, fault diagnosis and remote assistance services.

Professional customization team: Supports customizing the overall test plan based on the characteristics of the customer's products and industry standards, including sample holders, spray systems, and temperature and humidity control logic.

Welcome to consult and learn more about sample holder selection solutions. We look forward to providing you with the most suitable experimental equipment support.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia