Accelerated UV Testing Equipment Features and Benefits

1. Rapid Outdoor Weathering Results

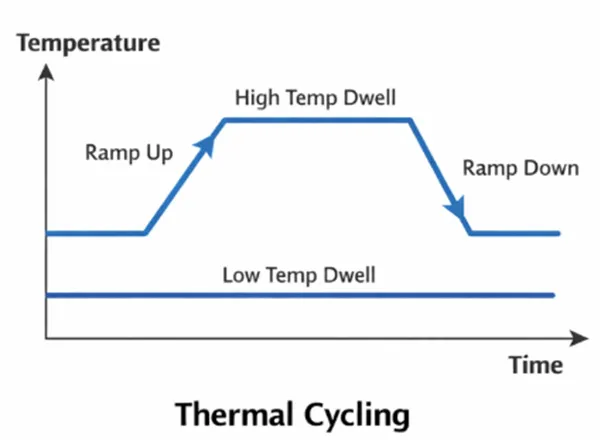

High-intensity UV lamps combined with precise temperature and humidity control dramatically shorten testing cycles. Outdoor exposure simulations that normally require years can be completed in days or weeks, accelerating product development and validation.

2. Controllable and Repeatable Testing Conditions

Critical parameters—including irradiance, wavelength, temperature, humidity, condensation, and spray cycles—are precisely controlled and highly repeatable, ensuring reliable comparison between materials and batches.

3. Compliance with International Testing Standards

Compliant with multiple international standards, including ASTM G154, ISO 4892, and SAE J2020, supporting standardized testing and certification.

4. Wide Range of Applications

Ideal for evaluating discoloration, cracking, chalking, gloss loss, mechanical degradation, and coating failure in:Plastics & polymers,Coatings & paints,Inks & pigments,Rubber & elastomers,Textiles,Electronic components & housings.

Technical Parameters of Accelerated UV Testing Equipment

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

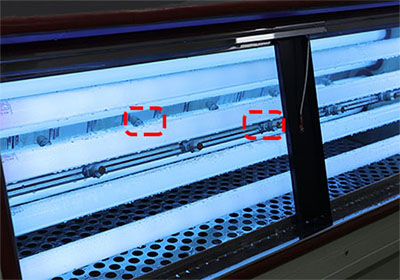

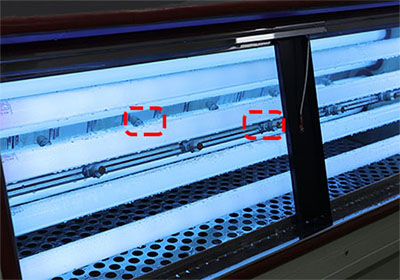

Details of Accelerated UV Testing Equipment

|  |

| UV Lamps | Sample Holder |

High-quality UV fluorescent lamps (UVA-340 or UVB-313) with stable wavelength and extended lifespan (1600+ hours). Adjustable light intensity with irradiance range: 0.3–20W/m² @ 340 nm, accommodating diverse testing requirements. Easy installation and maintenance with quick-change support to minimize downtime. Real-time display of operating current for each UV lamp facilitates monitoring of lamp status.

| Accommodates 56 standard samples measuring 75mm × 150mm. Aluminum alloy plate with return flange ensures corrosion resistance and easy cleaning. For special test specimens, LIB can customize 3D sample holders.

|

|  |

| Controller | Nozzles |

Features an intelligent touchscreen control system with an intuitive interface. Allows setting parameters for illumination, condensation, spraying, temperature, and humidity, with support for programmed cycles. Includes built-in data logging for easy export and analysis.

| High-precision water spray system simulates rain washdown and nighttime condensation. Part of a water recirculation system (with filtration), nozzles resist clogging. One row of nozzles on each side of the lamp tube. Ideal for combined UV + humidity + water spray testing.

|

FAQ - Accelerated UV Testing Equipment

Q1: Can this equipment be customized for large or special samples?

A: Yes. LIB industry provides customized Accelerated UV Testing Equipment, sample holders, lamp configurations, and control programs to meet non-standard testing needs.

Q2: What is the distance between lamps in the UV test chamber?

A: The distance between lamps in the UV test chamber is approximately 50 mm, meeting ASTM G154 and other related standards. This spacing ensures uniform UV light distribution, guaranteeing accurate and reliable weathering test results.

Q3: Does the Accelerated UV Testing Equipment have a water filtration system? Can water be reused?

A: Yes. The Accelerated UV Testing Equipment is equipped with an automatic water supply system and water filter to maintain stable water quality. During operation, water at the bottom of the chamber sustains high humidity. Overflow ports allow excess water to return to the water tank, enabling circulation and ensuring continuous testing while optimizing water use.

Call to Action – Get Your Accelerated UV Testing Solution

At LIB industry, we don’t just provide advanced Accelerated UV Testing Equipment —we offer a complete testing support experience to ensure your projects run smoothly:

Custom Solutions – Non-standard sample holders, 3D fixtures, and custom chamber sizes

Prompt Technical Support – Engineers respond within 24 hours for installation, operation, and troubleshooting guidance

Fast & Secure Delivery – Standard chambers shipped in 7–15 days; custom models 1–2 weeks, securely packaged

Installation & Training – On-site or remote training to ensure your team operates efficiently

Comprehensive Warranty – 36-month coverage, with optional extended support plans

Contact LIB industry today at inquiry@libtestchamber.com to request a customized quotation within 1–3 hours,discuss your specific testing requirements.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia