Stability testing is a fundamental requirement in pharmaceutical development, ensuring that drug substances and finished products maintain their safety, efficacy, and quality throughout their intended shelf life. A stability chamber provides a controlled environment—defined by precise temperature, humidity, and light conditions(optional)—to simulate long-term, intermediate, and accelerated storage scenarios. For pharmaceutical manufacturers, these chambers are not merely test equipment but essential tools for regulatory compliance, risk mitigation, and product lifecycle assurance.

This article provides a comprehensive breakdown of stability chamber functions, technical specifications, regulatory standards, validation requirements, and why high-precision systems—such as those engineered by LIB industry—play a critical role in pharmaceutical quality management.

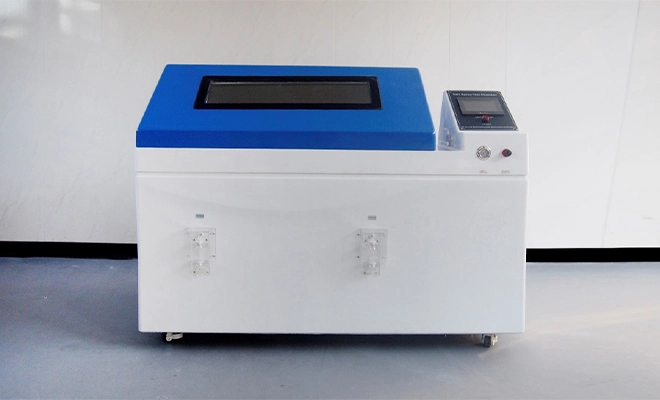

A stability chamber is a controlled environmental system engineered to maintain constant temperature and humidity conditions in line with international pharmaceutical stability testing standards.

|  |

Typical performance parameters include:

Temperature Range: -20°C to +150°C (customizable temperature range)

Temperature Accuracy: ±0.1°C

Temperature Uniformity: ±0.5°C

Humidity Range: 20%RH–98%RH

Humidity Uniformity: ±2.5%RH

Systems may be available as:

Reach-in stability chambers (100–1000 L)

Walk-in stability chambers (5 m³–100 m³)

Custom stability chambers for special pharmaceutical packaging or oversized loads

These precise environmental parameters ensure repeatable, validated test conditions for solid dose forms, injectables, vaccines, biologicals, and APIs.

Pharmaceutical products face degradation risks such as oxidation, hydrolysis, photolysis, polymorphic transition, and physical instability. A stability temperature humidity chamberhelps identify:

Shelf life and expiration dates

Storage requirements (25°C vs 30°C vs refrigerated conditions)

Packaging suitability (blister packs, HDPE bottles, vials, aluminum tubes)

Degradation pathways under stressImpacts of humidity, temperature cycling, and long-term exposure

Typical industry pain points include:

Unexpected OOS (Out of Specification) caused by poor chamber uniformity

Long-term tests running 12–36 months require high reliability

Audit failures due to incomplete 21 CFR Part 11 data logs

Need for stable performance in 24/7 operation

Multi-condition testing requiring several chambers or large walk-in rooms

A high-performance system minimizes these risks, ensuring data precision and regulatory compliance.

A pharmaceutical-grade stability chamber incorporates several advanced mechanical and control features:

PID microprocessor controller Self-optimizing algorithms Dual RTD sensors for accuracy SSR / solid state relays for stable power control |  |

Eco-friendly refrigerants Multi-stage refrigeration for tight control Hot-gas bypass for smooth modulation Low-vibration scroll compressors |  |

Uniform laminar airflow High-efficiency fans operating at constant RPM Air velocity 1~2 m/s for even distribution |  |

304 stainless steel interior Polyurethane foam insulation (100mm thickness) Magnetic door seals Optional viewing windows and LED lighting |  |

Over-temperature protection Low-water humidity protection Power-off memory recovery Door-open alarms |  |

Real-time trend charts USB/Ethernet data export Remote monitoring |  |

These mechanical and digital components ensure long-term stability and reproducibility, especially in multi-month pharmaceutical testing programs.

A compliant stability chamber must meet several international guidelines. Key standards include:

Defines long-term, intermediate, and accelerated testing conditions.

Additional guidance for global pharmaceutical stability programs.

Used for vaccines, proteins, and biologics.

Electronic records & signatures for data logging.

European requirements and climatic zone classifications.

Competence of testing and calibration laboratories for reproducible results.

Climatic Zones (ICH & WHO):

| Zone | Condition | Application |

| Zone I | 21°C / 45%RH | Temperate |

| Zone II | 25°C / 60%RH | Subtropical |

| Zone III | 30°C / 65%RH | Hot/dry |

| Zone IVa | 30°C / 75%RH | Hot/humid |

| Zone IVb | 30°C / 70%RH | Very humid (ASEAN) |

25°C ± 2°C / 60%RH ± 5%RH

Duration: 12–36 months

30°C ± 2°C / 65%RH ± 5%RH

Duration: 6–12 months

40°C ± 2°C / 75%RH ± 5%RH

Duration: 6 months

A stability chamber must maintain these conditions with extremely low deviation, ensuring accurate and audit-ready data.

Pharmaceutical stability chambers must be validated before use:

Utility check

Leveling and structural check

Controller installation

Component verification

Calibration certificates

Temperature accuracy tests

Humidity accuracy tests

Alarm and safety system validation

Data logging verification

Full-load & empty-load tests

Mapping with 9–15 sensors

72-hour stability test

Uniformity verification (±0.5°C & ±2.5%RH typical)

Validation ensures repeatable, reliable, compliant operation.

Stability chambers are used for:

Tablets & capsulesInjectables (vials, ampoules)

Vaccines & biologics

Eye drops & nasal sprays

Packaging material testing

API raw material studies

Shelf-life extension programs

Packaging compatibility analysis

Every product category requires tight tolerance and long-term operational reliability.

LIB industry specializes in precision environmental simulation equipment engineered for pharmaceutical compliance.

Key advantages include:

High accuracy: ±0.1°C temperature / ±1.5%RH

humidityUniformity optimized airflow design

Custom walk-in stability rooms up to 100 m³

Reliable 24/7 long-term operation

Full documentation: IQ/OQ/PQ + calibration + wiring diagrams

Global installation and remote support(3-year extended warranty and lifetime service)

Designed for robust, continuous operation, LIB industry chambers help pharmaceutical companies pass audits, reduce OOS events, and ensure product quality consistency.

Common conditions include 25°C/60%RH (long-term), 30°C/65%RH (intermediate), and 40°C/75%RH (accelerated).

Capacity, temperature range, humidity range, lighting, shelving, and door design can all be customized.

Yes—LIB industry builds reach-in chambers and walk-in stability rooms from 5 m³ to 100 m³.

Typically every 6–12 months depending on site SOPs and regulatory requirements.

For pharmaceutical teams seeking ICH-compliant, 21 CFR Part 11 ready, high-precision stability solutions, LIB industry delivers customized chambers engineered for long-term reliability and global regulatory compliance.Contact us inquiry@libtestchamber.com for specifications, customization options, or a formal quotation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia