In an increasingly globalized world, products are often exposed to a variety of environmental conditions before they reach consumers. One of the most challenging environments for many products is the coastal area, where exposure to salt, moisture, and humidity can significantly impact performance and longevity. To address these challenges, manufacturers utilize salt fog machines to simulate coastal conditions for rigorous product testing. This article explores how these machines function and the benefits they provide in ensuring product reliability.

Salt fog machine, also known as salt spray equipment, is specially designed testing devices that create a controlled environment to replicate the corrosive effects of saltwater. These machines generate a fine mist of saline solution, mimicking the conditions found in coastal areas. The primary purpose of these machines is to assess the durability and resistance of materials and coatings to corrosion and other forms of degradation.

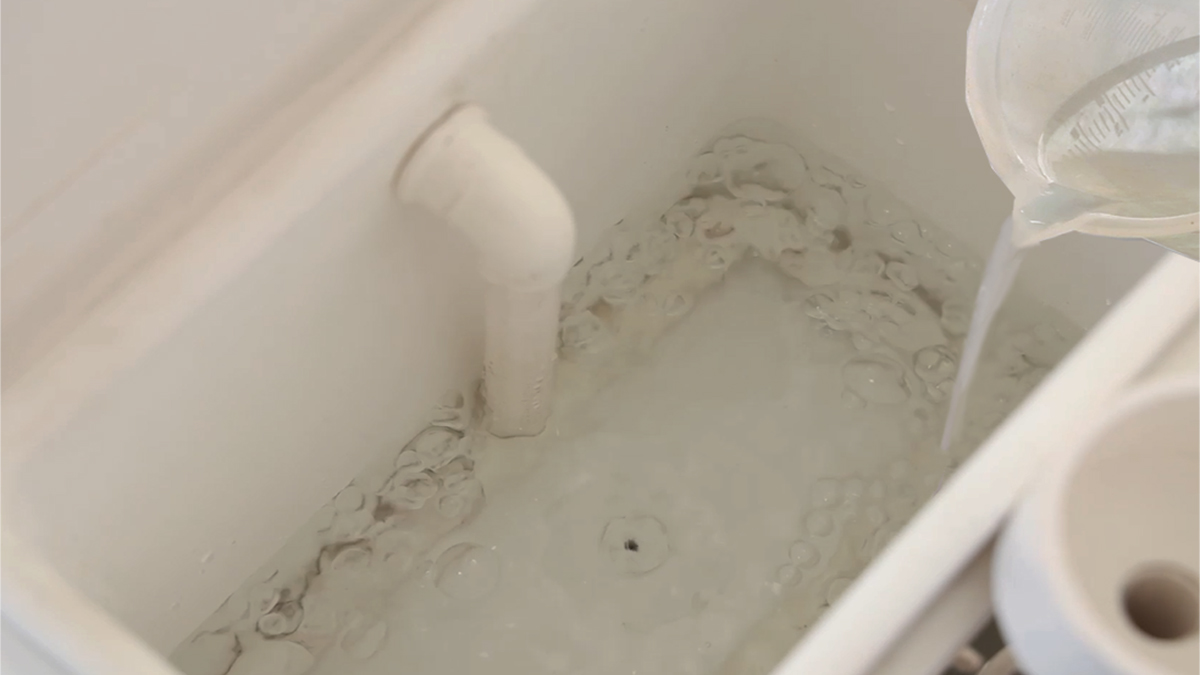

Salt fog machines operate by atomizing a saline solution, typically composed of sodium chloride (NaCl) and distilled water, into a fine mist. The chamber is maintained at a specific temperature and humidity level to ensure consistent testing conditions. The fog is circulated within the chamber, allowing for continuous exposure of test specimens to the corrosive environment.

The testing process can vary in duration, often lasting from a few hours to several days, depending on the specific requirements of the product being tested. After the exposure period, the specimens are examined for signs of corrosion, degradation, or other failures, providing critical data on their performance in real-world coastal conditions.

As one of leading environmental test chamber suppliers, our Salt fog machines are widely used across various industries, including automotive, aerospace, electronics, and construction. Here are some key applications:

1. Automotive Industry

In the automotive sector, manufacturers must ensure that vehicles can withstand harsh environmental conditions. Salt fog testing helps evaluate the corrosion resistance of metal components, coatings, and seals, ultimately contributing to the vehicle's longevity and safety.

2. Aerospace Industry

Aerospace components are often exposed to extreme conditions, including salt-laden air during flight. Salt fog machines simulate these conditions, allowing manufacturers to test critical parts such as fuselage, wings, and landing gear for potential corrosion issues.

3. Electronics

For electronic devices, exposure to moisture and salt can lead to significant failures. Salt fog testing helps manufacturers determine the reliability of circuit boards, connectors, and casings, ensuring that products can withstand exposure to humid or coastal environments.

4. Construction Materials

Building materials used in coastal regions must be resistant to corrosion and degradation. Salt fog machines help evaluate the performance of paints, coatings, and metal structures, ensuring they meet industry standards for durability.

Predictive Analysis: By simulating real-world conditions, salt fog machines provide valuable insights into how products will perform over time, allowing manufacturers to make informed decisions about design and materials.

Quality Assurance: Regular testing with salt fog machines helps maintain high-quality standards, reducing the risk of product failures and enhancing customer satisfaction.

Regulatory Compliance: Many industries are subject to strict regulations regarding corrosion resistance. Using salt fog machines aids in meeting these compliance standards, ensuring that products are safe and reliable.

Cost-Effective Testing: Conducting salt fog tests can be more cost-effective than field testing in coastal environments, providing quick and reliable results without the logistical challenges.

Salt fog machines play an essential role in the product testing lifecycle, providing manufacturers with the ability to simulate coastal conditions accurately. By understanding how these machines operate and their applications across various industries, companies can enhance their product development processes, ensuring that their products stand the test of time—even in the most challenging environments. As the demand for durable and reliable products continues to grow, the importance of salt fog testing will undoubtedly remain at the forefront of product innovation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia