In industries such as electric vehicles, automotive electronics, and industrial equipment manufacturing, IP69 waterproof compliance has become a standard requirement rather than an optional upgrade. Components are expected to withstand high-pressure, high-temperature water exposure during aggressive cleaning, outdoor operation, and harsh service environments.

However, as waterproof requirements increase, many laboratories face a growing challenge: how to complete IPX6K and IPX9K testing efficiently without increasing equipment count, labor cost, or compliance risk. This is where integrated IP69 waterproof testing equipment plays a decisive role in improving both testing efficiency and reliability.

|  |

Although often mentioned together, IPX6K and IPX9K are two independent waterproof test levels, each defined by distinct test conditions and performance requirements. Understanding this difference is essential when selecting IP69 waterproof testing equipment.

IPX6K and IPX9K differ in water pressure, flow rate, nozzle diameter, temperature, and test intent. They are not interchangeable parameters, but separate test levels that must be performed individually to achieve full IP69-related compliance.

| Item | IPX6K High-Pressure Water Jet Test | IPX9K High-Temperature High-Pressure Spray Test |

|---|---|---|

| Test Purpose | Simulates powerful water jets such as heavy rain and vehicle washing | Simulates aggressive industrial and automotive washdown |

| Typical Application | Outdoor equipment, vehicle components, exposed enclosures | Automotive parts, EV components, industrial housings |

| Water Pressure | High-pressure water jets (controlled pressure range) | Extremely high pressure, up to 10,000 kPa |

| Nozzle Diameter | Ø 6.3 mm | Ø 0.8 mm |

| Water Temperature | Ambient water temperature | Elevated water temperature, typically 80–88 °C |

| Spray Characteristics | Strong water jets from multiple directions | High-temperature, high-pressure spray impact |

| Test Severity | High | Very high (more severe level) |

| Test Objective | Verify resistance against strong water ingress | Verify resistance under extreme cleaning conditions |

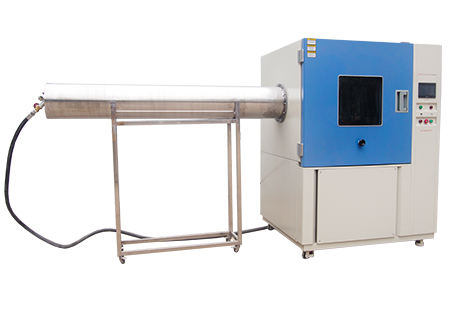

The LIB industry R6K9K-1200 is designed as an integrated IP69 waterproof testing equipment, capable of performing both IPX6K and IPX9K tests independently within a single system. Each test level operates with its own fully compliant parameters—without compromise, simplification, or manual reconfiguration.

Performing IPX6K and IPX9K tests separately has long been a bottleneck in waterproof validation workflows. Traditional approaches often rely on multiple machines or time-consuming manual adjustments.

Common inefficiencies include:

Separate equipment for IPX6K and IPX9K testing

Manual nozzle replacement between test levels

Recalibration of pressure and flow parameters

Sample relocation, increasing handling risk and downtime

These steps extend testing cycles and introduce unnecessary variability.

LIB industry addresses this challenge with an intelligent integrated control system. Test engineers can switch between IPX6K and IPX9K modes with a single command.

Key advantages include:

Automatic pressure adjustment from 1000 kPa to 10,000 kPa

Automatic nozzle positioning

No system shutdown between tests

No manual intervention required

By eliminating redundant setup steps, laboratories can:

Reduce preparation and transition time

Maintain continuous testing workflows

Lower labor dependency

Increase daily test throughput

The result is a measurable efficiency improvement of up to 50%, especially in high-volume or qualification-driven testing environments.

Model | R6K9K-1200 | ||

Interior Volume (L) | 1200 | ||

Parameter | Testing Platform Diameters | 600mm | |

Testing Platform Speed | 5±1 r.p.m | ||

Turntable loads | 50kgs | ||

Testing Platform Height | 200-400 mm (adjustable) | ||

IPX6K | Internal Diameter of Nozzle | 6.3mm | |

Water Flow Rate | 75 L/min +/- 5% | ||

Water pressure | 1000 Kpa | ||

Distance fromWater Spraying to Specimens | between 2.5 m and 3 m. | ||

IPX9K | Water Spray Angle | 0°, 30°, 60°, 90° | |

Water Spray Temperature | Ambient ~ +88℃ (Adjustable) | ||

Spray Nozzle | Four, 30 Seconds each position | ||

Distance fromWater Spraying to Specimens | 10~15cm | ||

Water Pressure | 8000-10000 Kpa (Adjustable) | ||

Water Flow Rate | 14L-16L/min | ||

| Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class | ||

Efficiency alone is not enough—repeatability and compliance accuracy are equally critical in IP69 waterproof testing.

The R6K9K-1200 features fully automated multi-angle spray testing, covering 0°, 30°, 60°, and 90° positions without manual adjustment. This ensures consistent exposure across all required orientations and eliminates operator-dependent variation.

High-pressure spray testing demands precise control. The system maintains:

Stable high-pressure output across the full test range

Consistent high-temperature water delivery up to 88 °C

Uniform spray performance throughout long test cycles

All test parameters are program-controlled through the PLC system. Once configured, each IPX6K or IPX9K test runs exactly as defined, delivering repeatable, audit-ready results.

An IP69 waterproof testing equipment is a long-term laboratory asset. Its true value lies not only in meeting test standards, but in durability, operational stability, intelligent control, and total cost of ownership over time.

The industrial-grade high-pressure pump system is engineered for extended operation under demanding conditions. It supports continuous high-pressure testing without performance degradation, ensuring stable output throughout long test cycles and high-frequency usage.

The test chamber is constructed from SUS304 stainless steel, providing:

Excellent corrosion resistance in wet and aggressive environments

Structural stability under high pressure and elevated water temperature

Long service life with minimal material fatigue

This robust mechanical design ensures consistent performance even under repeated IPX6K and IPX9K testing.

Stable operation leads to measurable cost advantages:

Fewer unplanned shutdowns

Reduced maintenance frequency

Longer service intervals

In practical terms, higher stability directly translates into a lower lifetime cost per test and improved return on investment (ROI).

Beyond mechanical durability, the system integrates intelligent control for modern laboratory operation. The PLC touchscreen offers intuitive local operation, while PC and APP access enable remote monitoring and control, supporting flexible and efficient lab management.

All IP69 waterproof test data is automatically recorded and can be exported directly for documentation and reporting. For QC managers and compliance teams, this simplifies report generation and strengthens traceability during internal reviews and external audits.

The built-in closed-loop water filtration system features a filtration accuracy of ≤ 0.03 mm, effectively preventing nozzle blockage and reducing maintenance workload. At the same time, water recycling minimizes water consumption, supporting sustainable laboratory operation and corporate ESG objectives.

Q1: Can the IP69 testing equipment perform tests beyond IPX6K and IPX9K?

A: Yes. LIB industry IP69 equipment can handle additional ingress protection levels, including dust tests (IP5X/IP6X) and water tests (IPX1–IPX6), allowing multiple tests in a single system.

Q2: Can the equipment be customized for different product sizes?

A: Absolutely. Chamber dimensions are adjustable, and optional immersion depths can be configured to fit various DUT sizes while maintaining full standard compliance.

Q3: Does the system comply with international standards?

A: Yes. It is compatible with IEC 60529, ISO 20653, and DIN 40050-9, ensuring reliable and standardized testing across diverse product types.

Q4: How does customization benefit laboratory operations?

A: Flexible configuration and expanded testing capabilities allow laboratories to consolidate multiple ingress protection tests within a single system, reducing equipment needs and improving workflow efficiency.

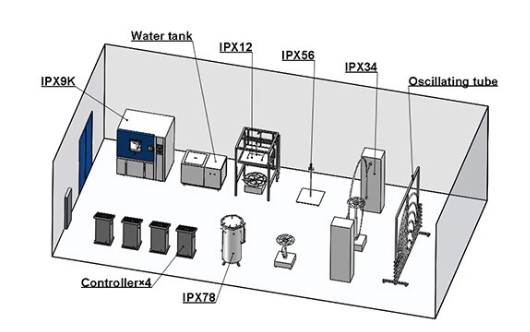

| LIB Industry Full Set Rain Test Chambers | |

| |

Looking to integrate IPX6K and IPX9K waterproof testing into one reliable IP69 system?

Contact LIB industry inquiry@libtestchamber.com to configure an industrial-grade solution backed by a 3-year warranty, lifelong technical support, and global service expertise—built for long-term stability and higher testing ROI.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia