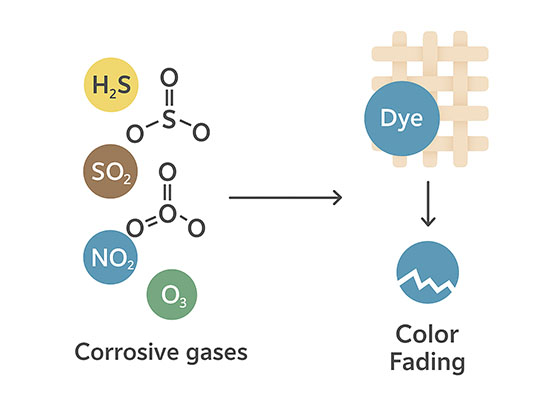

Modern textile laminates—used in automotive interiors, footwear linings, architectural panels, and industrial protective fabrics—are often exposed to polluted or chemically active environments. When hydrogen sulfide (H₂S), sulfur dioxide (SO₂), nitrogen dioxide (NO₂), ozone (O₃), or chlorine interact with dyes, adhesives, or polymer layers, serious damage can occur:

Fading and yellowing

Loss of color uniformity

Surface tackiness and cracking

Reduced bonding strength between laminate layers

To ensure long-term durability, corrosive gas color fastness testing has become a core requirement in international quality assessment. Accurate testing equipment is essential—and this is where LIB Industry excels.

Corrosive gases accelerate chemical reactions that attack dyes, fibers, and adhesive coatings. For example:

H₂S reacts with metal-based dyes and finishes, producing darkening or stains.

SO₂ dissolves into moisture, forming weak acids that cause fading and hydrolytic breakdown.

NO₂ oxidizes pigments, producing yellowish discoloration.

O₃ breaks polymer chains, creating cracking, brittleness, and surface haze.

Temperature and humidity intensify these reactions. Elevated moisture allows gases to dissolve more effectively, enabling deeper chemical penetration.

A controlled test environment—precise gas concentration, temperature stability, and humidity accuracy—is the scientific foundation for repeatable, meaningful test data.

Corrosive gas exposure is not a casual test—it is governed by internationally recognized standards:

ISO 105-G02 – Color fastness to sulfur dioxide

ISO 105-G03 – Color fastness to atmospheric NOx gases

IEC 60068-2-42 – Methods for exposing samples to SO₂ and H₂S

IEC 60068-2-43 – Single-gas corrosion testing

ASTM D1148 – Rubber deterioration by ozone exposure

LIB Industry’s noxious gas chambers can be configured to fully comply with these required test conditions.

Each corrosive gas reveals different aging mechanisms in textiles and laminates:

Gas | Main Failure Mode | Typical Use Case |

H₂S | Blackening, stain formation | Footwear, automotive interiors |

SO₂ | Acid fading, dye breakdown | Upholstery, architectural textiles |

NO₂ | Oxidation yellowing | Outdoor fabrics, laminates |

Cl₂ | Bleaching, polymer attack | Packaging laminates |

Cracking, surface brittleness | Rubberized or PU-coated textiles |

LIB Industry gas testing chambers support single-gas and multi-gas (mixed gas) testing,allowing product designers to evaluate multiple environmental stressors at once.

A typical color fastness evaluation includes:

Conditioning samples at 20–23°C, 50% RH

Setting gas concentration (commonly 1–200 ppm depending on standard)

Configuring environmental factors:

Temperature: 20–60°C

Humidity: 40–98% RH

Exposing for 24–48 hours (ISO standard exposures may reach 72–96 hours)

Post-test assessment using:

Gray scale for color change

Spectrophotometer (ΔE value)

Visual and microscopic surface inspection

Repeatability is critical—only a stable gas chamber can produce valid comparative data.

Gas Type | Concentration Range | Accuracy / Tolerance | Notes |

SO₂ | 100 ~ 500 ppb | ±20 ppb | Adjustable |

H₂S | 10 ~ 100 ppb | ±20 ppb | |

NO₂ | 200 ppb | ±20 ppb | |

Cl₂ | 10 ~ 20 ppb | ±5 ppb | |

|  | ||

Additional Features:

High-precision mass flow controllers (MFC)

Closed-loop feedback for stable gas mixing

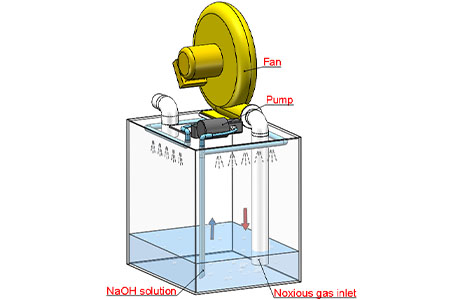

Safe and clean residual noxious gas treatment system

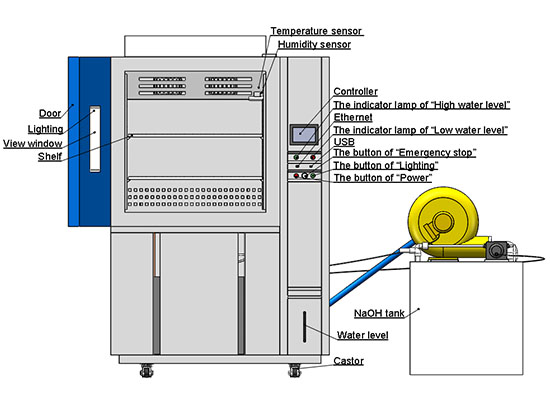

Parameter | Specification |

Temperature Range | 15 ℃ ~ 80 ℃ |

Temperature Stability | ±0.5°C |

Humidity Range | 30–98% RH |

Humidity Stability | ±2.5%RH |

Uniform, consistent climate control ensures reliable color fastness evaluation.

SUS316 stainless steel interior Large observation window with anti-fog design LED workroom lighting Optimized airflow for uniform gas distribution |

|

7-inch touch screen controller Real-time monitoring of gas concentration, temperature, humidity Multi-step programmable testing cycles USB data export + Ethernet remote monitoring |

|

Gas leakage alarms Automatic gas shutoff system NAOH solution tank to dilutes noxious gas Over-temperature and electrical protection Safety interlock for door opening |

|

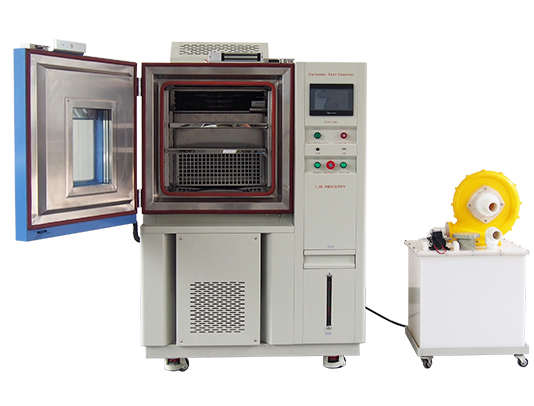

LIB Industry gas test chambers are designed to run 48-hour continuous tests with exceptional stability and safety.

Yes. It supports H₂S, SO₂, NO₂, Cl₂, O₃, and any combination required by your standard or internal specifications.

Most labs use 100–500L, while large automotive panels may require 800–1000L.

Yes. The system can generate SO₂ + NO₂ mixtures commonly used in automotive OEM specifications.

Through leak detection, automatic gas shutoff, purified exhaust, over-temperature protection, and safety interlocks.

16+ years of specialization in environmental simulation

Custom chamber sizes from 100L to 1000L+

Support for custom gas types and gas concentration ranges

Long-life components designed for chemical resistance

Used by textile labs, automotive suppliers, and third-party testing centers worldwide

1~3 hours technical response

Short production cycle with factory-direct pricing

On-site installation and training available

Spare parts in stock for rapid service

3-year extended warranty and lifetime technical support

Reliable test results start with precise environmental control.

LIB Industry’s corrosive noxious gas test chambers provide the accuracy, stability, and safety that modern textile laminate testing demands.

Contact LIB Industry today inquiry@libtestchamber.com for a customized H₂S / SO₂ / NO₂ /Cl₂ mixed-gas test solution designed for long-term reliability and fast delivery

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia