In the industrial heating world, certain challenges push ordinary ovens to their limits. One such project in 2020 required heating a 170 mm diameter, 6-meter-long steel casing, with a built-in tool for setting bridge plugs, while external wires and hydraulic lines extended from the ends for monitoring and testing. The workpiece was heavy, the setup complex, and precision was critical.

Most conventional ovens simply cannot handle such lengths, weights, or the need for external connections. This is where LIB Industry’s engineering expertise turned a nearly impossible task into a successful project.

Heating a 6-meter, 170 mm diameter steel casing with internal tooling

Heavy weight requiring safe loading and unloading

External wires and hydraulic lines that must remain connected during testing

Precise and stable temperature control up to 300°C

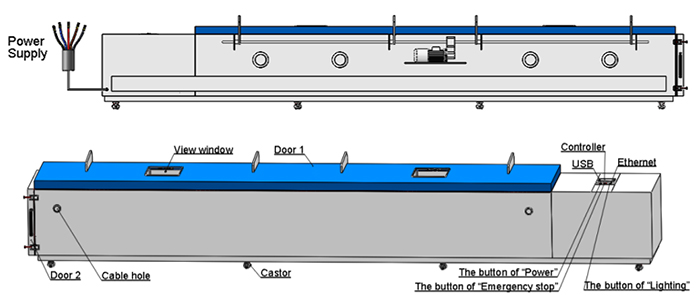

Ultra-long, seamless chamber design for consistent heating

Top-opening door + removable side panel for easy handling and wiring

Reinforced structure to handle heavy loads safely

Precision temperature control from ambient up to 300°C

Customer approved the solution and placed PO for O-023

The design became a benchmark for future industrial oven development

Four years later, the same customer approached LIB Industry again for a similar yet updated solution, proving long-term trust in the brand

The O-023 project demonstrates that customization is not an exception—it is the origin of LIB Industry’s design philosophy.

Every extreme project, whether it involves ultra-long, heavy, or complex workpieces, feeds directly into the engineering DNA of standard industrial ovens.

This ensures that every standard oven carries the reliability, uniformity, and durability validated by real-world, high-demand projects.

Even our standard industrial ovens inherit the engineering insights from custom projects:

Thermal uniformity: Forced-air circulation ensures no dead zones

Structural reliability: Reinforced frame and floor based on heavy-duty designs

Control & Monitoring: Programmable controllers, remote monitoring, and data logging

Safety: Industrial-grade over-temperature protection, power-off recovery, and interlocks

Typical Applications:

Metal parts preheating and aging

Automotive component drying

Composite material curing

Laboratory research and precision heat treatment

Model | O-100 | O-225 | O-500 | O-800 | O-1000 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Temperature Range | A: Ambient ~+250 ℃ B: Ambient ~+400 ℃ C: Ambient ~+900 ℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Heating Rate | 6 ℃ / min | ||||

Heating Element | Nichrome heater | ||||

Controller | Programmable color LCD touch screen controller, Ethernet connection | ||||

Safety Device | Over-temperature Protection; Over-current Protection; Phase Sequence Protection; Earth leakage Protection | ||||

Interior Material | SUS304 stainless steel | ||||

| Thermal Insulation | Polyurethane foam (Refractory brick) | ||||

| |||||

Volume Options: Benchtop to walk-in scale

Standard ovens now offer the confidence of a heavy-duty custom solution, ready for the majority of industrial applications.

Some materials and processes cannot tolerate air due to oxidation, bubbles, or solvent retention. For these applications, vacuum ovens extend the same proven engineering principles into a controlled, low-pressure environment:

Electronics & semiconductors: precision drying and curing

Adhesives & resins: degassing without oxidation

Battery & composite materials: high-precision thermal processing

Continuity with standard ovens:

Same temperature control logic

Same structural reliability

Enhanced sealing and pressure management

Model | VO-20 | VO-30 | VO-50 | VO-90 | VO-125 |

Interior Volume | 20L | 30L | 50L | 90L | 125L |

Temperature Range | +35 ℃ ~+350 ℃ | ||||

Heating Rate | 6 ℃ / min | ||||

Vacuum degree | -133pa | ||||

Controller | Programmable color LCD touch screen controller | ||||

Ethernet connection, PC Link(Option) | |||||

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class | ||||

Safety Device | Over-temperature Protection; Over-current Protection; Earth leakage Protection, Phase Sequence Protection | ||||

Interior Material | SUS316 stainless steel | ||||

Thermal Insulation | Polyurethane foam | ||||

| |||||

Whether you need a heavy-duty custom oven or a high-performance standard oven, LIB Industry delivers solutions built on proven engineering expertise. Share your load, dimensions, temperature range, and process requirements—our engineers will design the right oven for you.

Peace of mind guaranteed: 3-year warranty, lifelong technical support, and global spare parts ensure minimal downtime. Our 24/7 English-speaking team is ready to assist worldwide, with detailed guidance for shipping, installation, and safe operation.

1. What is the maximum temperature an oven can reach?

Ovens can reach temperatures from 250°C up to 1200°C, depending on your process requirements. LIB Industry also provides custom temperature and size solutions to meet specific experimental needs.

2. What insulation materials are used for different temperature ranges?

Below 300°C: Polyurethane and thermal insulation cotton

Above 300°C: Fire-resistant bricks to ensure effective heat retention and equipment safety under high temperatures

3. What after-sales support can I expect?

LIB Industry offers 3-year warranty and lifelong technical support. If an issue cannot be solved remotely, a replacement unit is provided at no extra cost. Critical spare parts are stocked in international centers for fast delivery, while detailed instructions ensure safe shipping, installation, and operation worldwide.

Contact us now to discuss your oven requirements and receive a tailored solution: inquiry@libtestchamber.com

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia