Features and Benefits of Xenon Arc Light Fastness and Weathering Tester

1. True Full-Spectrum Sunlight Simulation

Using a xenon arc lamp, the tester reproduces UV, visible, and infrared radiation that closely matches natural daylight. This ensures results that accurately reflect real outdoor environmental exposure, providing reliable predictions of long-term material performance.

2. Accelerated Aging with Precise Environmental Control

Independent control of irradiance, black panel temperature, chamber temperature, humidity, and water spray/condensation cycles allows highly repeatable conditions for accelerated light and weather aging tests.

3. Compliance with International Standards

Fully aligned with test requirements such as ISO 4892-2, ASTM G155, AATCC TM16, and SAE J2527. This guarantees test consistency and supports global certification, supplier qualification, and production quality assurance.

4. Energy-Efficient Cooling and Lamp System

Optimized airflow design and high-efficiency water cooling reduce heat load and extend xenon lamp lifespan to 1600 hrs, lowering operating costs and improving long-duration stability for demanding test schedules.

5. Modular Configurations and Customizable Test Profiles

User-defined test programs allow customized cycles for sunlight exposure, humidity, dark periods, and water spray — ideal for comparing materials, simulating specific climates, or recreating end-user environmental conditions for R&D validation.

Core Technical Parameters of Xenon Arc Light Fastness and Weathering Tester

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Details of Xenon Arc Light Fastness and Weathering Tester

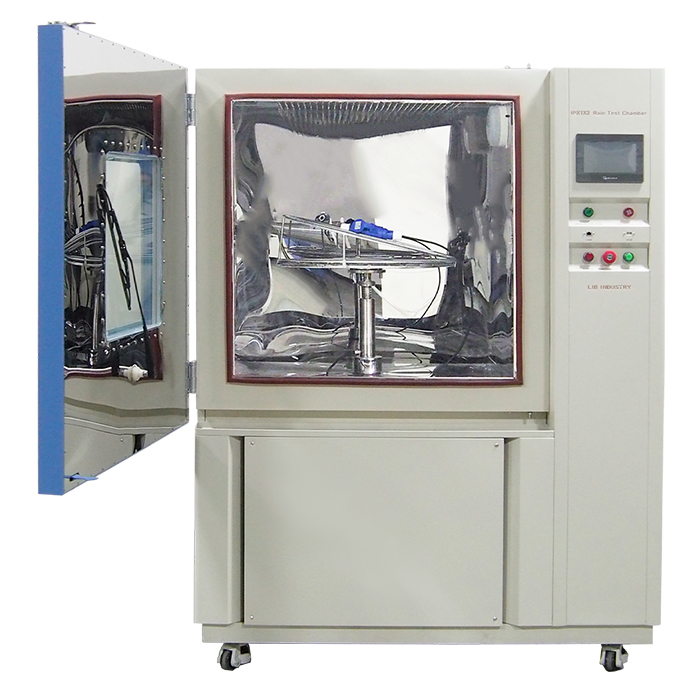

| Workroom | Mirror-finish SUS304 stainless steel material, allowing for durability and uniform light distribution. Available sizes: From standard models to walk-in xenon weathering testers Efficient air circulation and water spray systems precisely control temperature, humidity, and condensation cycles.

|

|

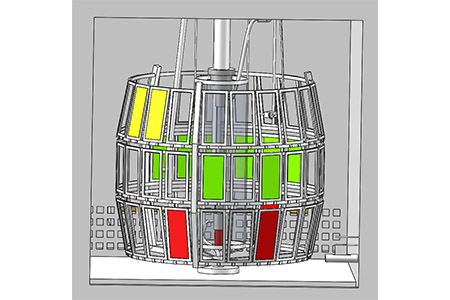

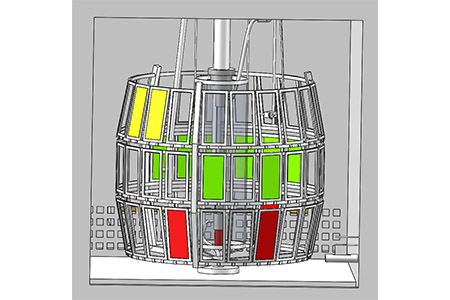

| Specimen Holder | Supports multiple specimens with automatic or manual rotation for uniform exposure. Specimen sizes: 95*200 mm – 200×200 mm, capacity:42 pieces. Easy installation and removal of samples.

|  |

| Optical Filters | Common types: Daylight Q, Daylight B/B, Window Q, Window B/B filters.Daylight (280–800 nm), Window Glass (295–800 nm). Filters are replaceable, corrosion-resistant, and maintain stable spectral transmission. Adjustable for custom UV intensity and spectrum.

|  |

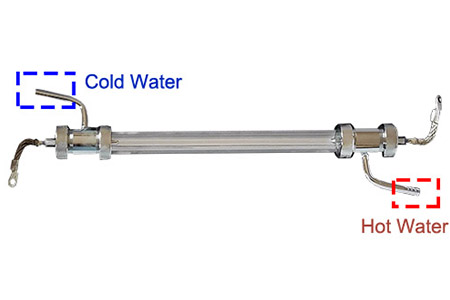

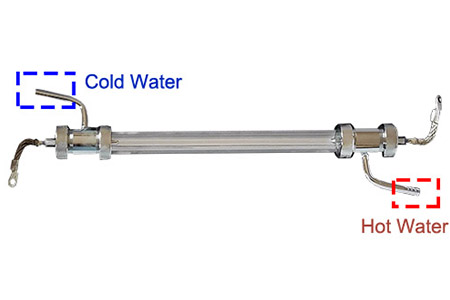

| Xenon Lamp | High-intensity full-spectrum water-cooled xenon light closely replicates natural sunlight. Adjustable irradiance: 35-150W/m². Lamp life: 1600 hours, with efficient cooling for stable output. Ensures long-term stability during prolonged test cycles.

|  |

| Controller System | Advanced digital controller allows precise programming of irradiance, temperature, humidity, and water spray cycles. Features real-time monitoring, trend recording, alarms, and USB/Ethernet data export. Customizable, repeatable test programs support standards: ISO 4892-2, ASTM G155, SAE J2527.

|  |

Expert Tips – Xenon Arc Light Fastness and Weathering Tester

Q1: How often should the optical filters and xenon lamps be maintained or replaced?

A: Typically, optical filters should be inspected annually for spectral stability and cleanliness, while xenon lamps have a service life of 1600 hours. Replacement depends on usage intensity and test requirements to ensure accurate light exposure.

Q2: Does the controller interface support multiple languages?

A: Yes, the advanced digital controller supports multi-language interfaces, making operation intuitive for international users.

Q3: Does LIB Industry offer non-standard or custom configurations?

A: Absolutely. LIB Industry provides customized chamber sizes, lamp arrangements, test programs, and environmental control options to meet specific R&D or production testing requirements.

Contact LIB industry today at inquiry@libtestchamber.com to discuss your testing needs, get a tailored solution, and receive expert guidance from our engineering team.

Fast Delivery | Custom Configurations | 3-Year Warranty & Lifetime Technical Support.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia