In the anti-corrosion testing of materials, salt spray test is a classic and efficient environmental accelerated testing method. It helps enterprises assess the corrosion resistance of products in damp and high-salt environments, and is an important means of routine quality control in industries such as coating, electroplating, and automotive parts.

As customer standards become increasingly strict, traditional neutral salt spray (NSS) tests can no longer meet all testing scenarios, and more and more enterprises are beginning to pay attention to cyclic corrosion tests (CCT). So, what exactly is the difference between NSS and CCT? How to choose the right model of test chamber?

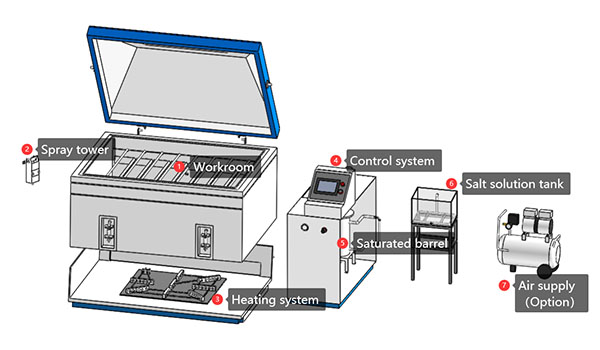

The NSS (Neutral Salt Spray) test is the most fundamental and widely used salt spray test method. It simulates corrosion conditions in a constant temperature environment through continuous spraying and is often used for preliminary screening of anti-corrosion performance or for pre-factory testing.

Standards: ASTM B117, ISO 9227

Temperature: 35℃ ± 1℃

Salt water concentration: 5% NaCl solution

Spray sedimentation rate: 1-2 mL/80cm²/h

LIB adaptation devices: S-150, S-250, S-750, S-010, S-016, S-020

Suitable application scenarios: hardware parts, surface treatment, conventional electroplated parts, and economical anti-corrosion verification.

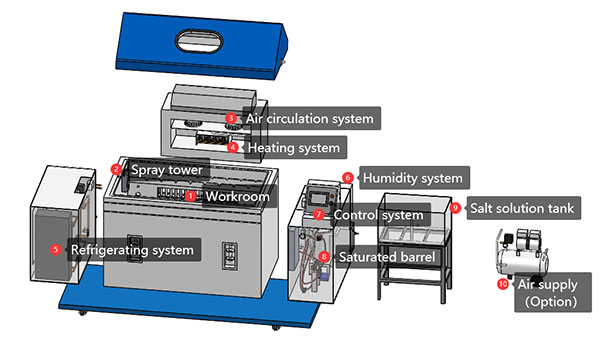

CCT (Cyclic Corrosion Test), namely cyclic corrosion test, is a multi-stage compound climate simulation test method. It reflects the complex corrosion challenges faced by products in the natural environment more truly through alternating cycles of salt spray, drying, damp heat, condensation and other processes.

Standards: ISO 16701, SAE J2334

Typical testing process:

Salt spray stage (35℃, 5% salt spray) for 4 hours

Drying stage (60℃, 0%RH) : 2 hours

The wetting stage (50℃, 95%RH) lasts for 2 hours

The cycle repeats for 48 to 1,000 hours

LIB compatible CCT test chamber: SC-010, SC-016, SC-020

Suitable application scenarios: automotive parts, outdoor equipment, high-end electronics and other products with high requirements for long-term corrosion resistance.

Comparison dimensions | NSS neutral salt spray test | CCT cyclic corrosion test |

Simulated environment | single salt spray climate | multi-stage natural climate |

Experimental results | accelerate the screening and the initial evaluation of the protective effect | closer to the actual service life and failure mode |

Equipment complexity | complex but easy to operate, with few programs | precise control, and requires program switching |

Applicable standards: | ASTM B117 | ISO 16701, VDA, SAE |

Still not sure which one to choose? Welcome to contact us for test plans and equipment configuration suggestions!

LIB can provide salt spray test chambers of various specifications in the S series (NSS) and CCT series to meet the testing requirements of different levels. It supports non-standard customization and remote technical support, helping enterprises build professional testing capabilities.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia