In today's rapidly advancing technological landscape, the durability and longevity of materials are of paramount importance, particularly in industries such as automotive, aerospace, construction, and consumer goods. One of the most critical environmental factors that can affect the performance of materials is ozone exposure.

LIB Industry Ozone aging test chambers have emerged as essential tools for predicting material performance over time by simulating the effects of ozone on various materials.

Ozone (O3) is a reactive gas that occurs naturally in the Earth's atmosphere. While it plays a crucial role in protecting the planet from harmful ultraviolet radiation, it can also lead to the degradation of various materials, particularly elastomers, plastics, and coatings. Ozone can cause cracking, discoloration, loss of mechanical properties, and overall material failure. Therefore, understanding how materials respond to ozone exposure is vital for ensuring their reliability and performance in real-world applications.

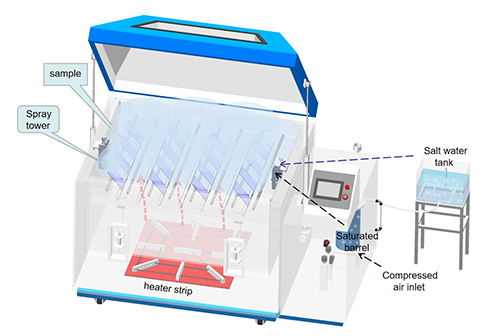

An ozone aging test chamber is a controlled environment designed to simulate the effects of ozone on materials over time. These chambers allow researchers and manufacturers to expose samples to specific concentrations of ozone at controlled temperatures and humidity levels. The goal is to accelerate the aging process, enabling the evaluation of a material's durability and performance under ozone stress in a fraction of the time it would take in natural conditions.

Key Features of Ozone Aging Test Chambers

1. Controlled Environment: The chambers maintain precise temperature, humidity, and ozone concentration levels, providing a consistent testing environment.

2. Customizable Testing Protocols: Users can design specific testing protocols to mimic real-world conditions, allowing for tailored assessments of material performance.

3. Monitoring Capabilities: Advanced chambers are equipped with monitoring systems that track changes in material properties throughout the testing period.

4. Data Analysis Tools: Many ozone aging test chambers come with integrated software for analyzing the data collected during tests, helping researchers draw meaningful conclusions.

1. Accelerated Testing: By simulating ozone exposure in a controlled environment, manufacturers can obtain results much faster than through traditional long-term aging methods.

2. Material Selection and Improvement: The insights gained from these tests enable companies to select the most suitable materials for specific applications and improve existing materials to enhance their resistance to ozone degradation.

3. Quality Assurance: Ozone aging tests can serve as a quality control measure, ensuring that products meet industry standards and customer expectations for durability.

4. Regulatory Compliance: Many industries are subject to regulations regarding material performance. Ozone aging test chambers help companies comply with these regulations by providing essential data on material longevity.

Ozone aging test chambers are invaluable tools in the quest to predict material performance over time. By simulating the effects of ozone exposure, these chambers enable manufacturers to assess the durability of materials, improve product designs, and ensure compliance with industry standards. As technology continues to evolve, the role of ozone aging test chambers will become even more critical in the development of materials that can withstand the challenges of a changing environment. Investing in these testing capabilities not only enhances product quality but also contributes to greater customer satisfaction and long-term success in various industries.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia