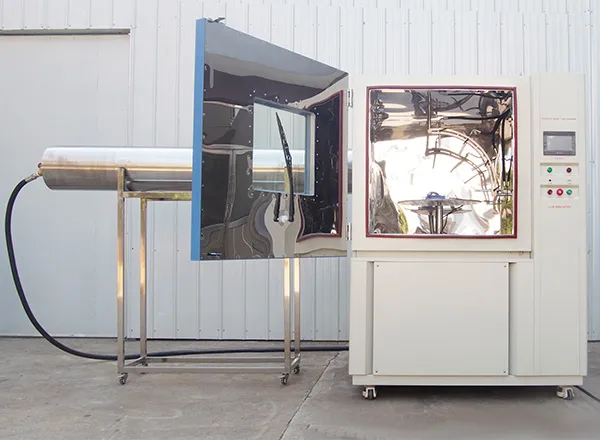

Temperature Shock Test Chamber Features and Benefits

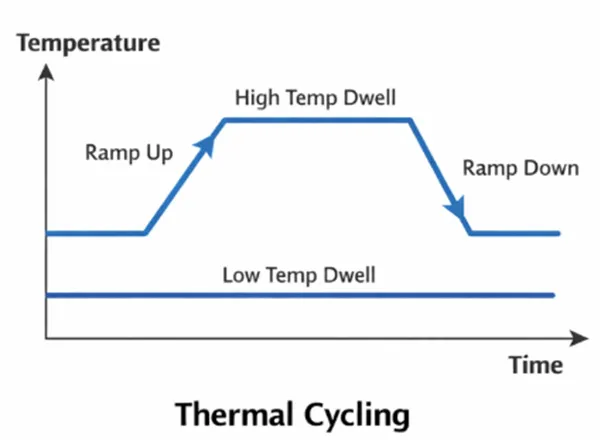

1. Ultra-Fast Temperature Switching

Samples are physically moved between hot and cold zones within 3 seconds, ensuring immediate thermal stress and accurate simulation of real-world conditions.

2. Ideal for Small and Medium-Sized Test Samples

Especially suited for components like ICs, PCBs, sensors, and automotive electronics, where fast response to temperature change is critical.

3. Flexible and Customizable Testing

Supports programmable temperature ranges, holding times, and shock cycles—ideal for various test standards including MIL-STD, JEDEC, and IEC requirements.

4. Precise Thermal Control

Advanced PID controllers and thermal sensors ensure temperature accuracy and stability, even during rapid transitions.

Specifications of Temperature Shock Test Chamber

Model | TS-162 | TS-340 | TS-500 | TS-1000 |

Internal Dimensions (mm) | 300*300*250 | 450*450*360 | 650*650*500 | 850*850*700 |

Overall Dimension (mm) | 1560*870*1545 | 1710*1020*1845 | 1910*1220*2265 | 2110*1420*2665 |

Interior Volume (mm) | 22L | 72L | 211L | 505L |

Loading Capacity | 20kg | 30kg | 50kg | 60kg |

Pre-heat Room | Upper limit Temperature | +220℃ |

Heating Time | Ambient ~ + 200℃, within 30 minutes |

Pre-cool Room | Lower limit Temperature | -75℃ |

Cooling time | Ambient ~ -70℃, within 30 minutes |

Test Room | High Temperature Exposure Range | Ambient +20 ~ +200°C |

Low temperature Exposure Range | –65 ~ -5°C |

Temperature Fluctuation | ≤±0.5℃ |

Temperature Deviation | ≤±3 ℃ |

Temperature Recovery Time | Within 5 minutes |

Cooling System | Mechanical compression refrigeration system |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Safety Device | Over-temperature protection, Over-current protection; Refrigerant high-pressure protection; Earth leakage protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 2 shelves |

Configuration of Temperature Shock Test Chamber

Test Basket | The SUS304 stainless steel test basket moves smoothly between the high-temperature and low-temperature zones, ensuring that the test piece is not affected. The test holes are located at the top of the basket(typically Ø50mm or customized) to allow external wiring, sensors, or power lines to pass through.

|

|

Intelligent Touchscreen Controller | PLC touch screen controller, supporting multi-stage program setting, real-time temperature tracking, automatic loop execution and remote monitoring. The intuitive interface is easy to operate and highly accurate.

|  |

Refrigeration System | Cascade refrigeration system, high-quality compressors and environmentally friendly refrigerants. Stable and reliable, with rapid cooling. |  |

Independent air circulation | Both the hot chamber and the cold chamber are equipped with circulating fans, ensuring uniform airflow and minimizing temperature gradients, thereby enhancing the consistency of thermal shock. |  |

In addition to the two-zones temperature shock test chamber, LIB also has a three-zones thermal shock test chamber and a thermal cycling testing equipment. If you have any testing requirements, please leave them and the LIB team will provide you with professional equipment selection suggestions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia