Aerospace components operate under some of the harshest environmental conditions in the world. From the sub-zero temperatures experienced at high altitudes to high heat and humidity during ground storage, components are continually exposed to stress. Even minor material degradation, electronic malfunctions, or mechanical inconsistencies can lead to costly repairs, flight delays, or, in extreme cases, safety incidents.

Aerospace components operate under some of the harshest environmental conditions in the world. From the sub-zero temperatures experienced at high altitudes to high heat and humidity during ground storage, components are continually exposed to stress. Even minor material degradation, electronic malfunctions, or mechanical inconsistencies can lead to costly repairs, flight delays, or, in extreme cases, safety incidents.

To address these challenges, aerospace manufacturers increasingly rely on Temperature Humidity Laboratory Climatic Test Chambers. These advanced systems allow engineers to replicate real-world temperature and humidity conditions in a controlled laboratory setting, enabling early detection of potential failures. By integrating these chambers into the testing workflow, manufacturers ensure their components are reliable, durable, and fully compliant with aerospace standards.

The stakes in aerospace are high, and testing is no longer optional—it’s a requirement. The right testing solution not only prevents component failures but also reduces production costs, accelerates product development, and improves customer trust.

Aircraft components face unique environmental stresses that make testing critical:

Electronic Systems: Sensitive avionics and control units are prone to thermal expansion, condensation, and corrosion. Rapid temperature fluctuations and high humidity cycles can trigger latent defects or malfunctions.

Composite Materials: Structural composites may warp, crack, or delaminate when exposed to alternating hot and humid or cold and dry conditions. Such deformations can compromise structural integrity and safety.

Seals, Gaskets, and Lubricants: Rubber seals, O-rings, and lubricants are vulnerable to prolonged exposure to heat and moisture. Degradation can lead to leakage, friction issues, or mechanical failure.

Sensors and Small-Scale Components: Tiny sensors and connectors may fail under environmental stress, jeopardizing the functionality of larger systems.

Without controlled laboratory testing, these vulnerabilities often remain undetected until the components are in service, where corrections are far more costly and risky.

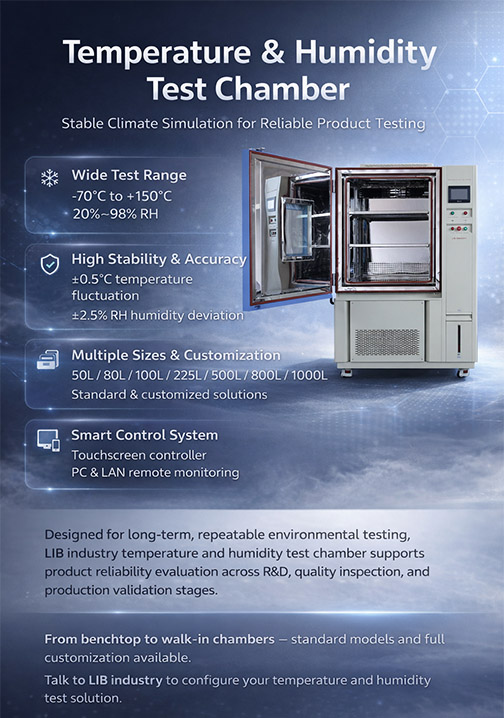

A temperature humidity environmental control chamber is specifically designed to meet the rigorous demands of aerospace testing. Its capabilities ensure that every component is thoroughly evaluated before deployment.

|  | ||||

| Name | Temperature Humidity Chamber | ||||

Temperature range | -20℃ ~+150 ℃ | ||||

Low type | A: -40℃ B:-70℃ C -86℃ | ||||

Humidity Range | 20%-98%RH | ||||

Temperature deviation | ± 2.0 ℃ | ||||

Heating rate | 3 ℃ / min | ||||

Cooling rate | 1 ℃ / min | ||||

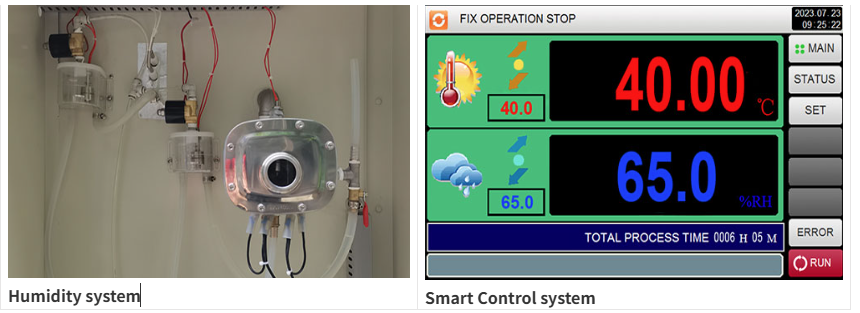

Controller | Programmable color LCD touch screen controller, Multi-language interface, Ethernet , USB | ||||

Refrigerant | Environmentally friendly refrigerant, meeting GWP emission requirements | ||||

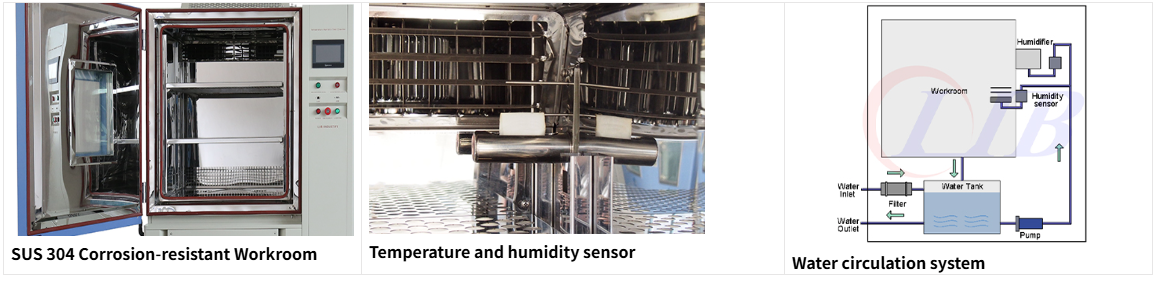

Interior material | SUS304 stainless steel | ||||

Standard configuration | 1 Cable hole (Φ 50) with plug; 2 shelves | ||||

Timing Function | 0.1~999.9 (S,M,H) settable | ||||

Simulates extreme operational conditions ranging from -70 °C to +150 °C.

Rapid thermal cycling evaluates components’ resistance to temperature shocks.

Extended exposure testing allows engineers to assess material aging and thermal stress over time.

Adjustable humidity levels, from near-zero to near-saturation, simulate dry or tropical conditions.

Rapid humidity transitions mimic real-world environmental fluctuations.

Uniform water circulation ensures consistent exposure across all samples.

Multi-language touchscreen interfaces simplify operation for global teams.

Up to 120 programmable test programs, each with 100 segments, allow precise simulation of complex cycles.

Real-time monitoring and data logging ensure repeatable and traceable test results.

Optional remote monitoring and control provide flexibility for modern aerospace laboratories.

Manual or automatic water filling maintains stable humidity conditions.

Continuous circulation prevents localized condensation, ensuring uniform exposure.

Designed for minimal maintenance, with corrosion-resistant SUS304 stainless steel construction.

Our chambers are engineered to meet the most stringent aerospace and environmental standards:

MIL-STD-810H: Environmental Engineering Considerations for Military Equipment

RTCA DO-160G: Environmental Conditions and Test Procedures for Airborne Equipment

IEC 60068-2: Environmental Testing for Temperature and Humidity

ASTM D5230 / ASTM D2247: Humidity and Corrosion Testing

By adhering to these standards, our Temperature Humidity Laboratory Climatic Test Chambers provide verified results that support certification processes and ensure product reliability.

LIB industry provides a complete range of Temperature & Humidity Test Chambers, designed to meet the diverse testing needs of aerospace labs—from small electronic components to full-scale subassemblies. Each model ensures precise control of temperature and humidity, allowing engineers to verify reliability, durability, and performance under real-world conditions while complying with aerospace standards.

Temperature Range: –20 °C to +150 °C / –40 °C to +150 °C / –70 °C to +150 °C

Humidity Range: 20–98 % RH

Ideal For: Small electronics, avionics sensors, and precision components

Key Features:

Rapid temperature and humidity cycling for early-stage testing

Uniform exposure ensures accurate results for sensitive components

Meets MIL-STD-810H, RTCA DO-160G, and IEC 60068-2 standards

Application: Subassemblies, mid-volume testing, and integrated components

Advantages:

Larger internal volume allows simultaneous testing of multiple components

Fully programmable cycles for thermal and humidity stress simulations

Standards supported: MIL-STD-810H, RTCA DO-160G, ASTM D2247

Ideal Use Cases: Avionics modules, control units, small composite panels

Application: Full-scale component or system testing

Capabilities:

Ideal for large aerospace assemblies, environmental simulation of storage and operational conditions

Customizable internal dimensions, temperature, and humidity ranges

Standards supported: MIL-STD-810H, RTCA DO-160G

Use Cases: Full avionics racks, structural assemblies, high-volume laboratory tests

Temperature Range: –70 °C to +220 °C

Application: Rapid thermal cycling for reliability studies

Capabilities:

Specimens transferred from cold to hot zones within 3 seconds

Accelerates failure detection under extreme thermal stress

Compliant with MIL-STD-810H thermal shock protocols

Temperature Range: –70 °C to +170 °C

Humidity Range: 20–95 % RH

Heating/Cooling Rate: ≥10 °C/min

Application: EV and Li-ion battery modules, aerospace power systems

Standards Supported: IEC 60068-2, MIL-STD-810H

Key Benefits: Rapid temperature cycling to ensure battery safety, reliability, and performance

1. Electronic Module Reliability Testing

Rapid temperature and humidity cycling reveals latent defects in avionics and control systems.

Engineers use temperature and humidity test chambers to simulate operational flight conditions, verifying that electronics perform under stress before installation.

2. Composite Material Assessment

High-precision environmental control exposes structural composites to extreme heat, cold, and humidity.

Warping, delamination, or cracking is identified early, and design improvements can be implemented before production.

Testing aligns with RTCA DO-160G standards for material durability under variable climates.

3. Seals and Lubricant Durability Evaluation

Long-term exposure under high humidity and temperature ensures gaskets, O-rings, and lubricants maintain functionality.

Chambers allow repeatable simulation of MIL-STD-810H humidity cycles, confirming performance under real-world stresses.

4. Sensors and Small Components Testing

Compact electronic or mechanical sensors can be subjected to precise temperature and humidity cycles to detect micro-failures.

Temperature humidity environmental control chambers enable accelerated aging tests, ensuring components meet operational reliability expectations.

5. Full-System Testing

Chambers can accommodate multiple components simultaneously, simulating interactions between electronic, mechanical, and composite elements.

Provides integrated testing data to engineers, reducing the risk of unexpected failures in assembly or operation.

These applications demonstrate that our chambers not only detect potential failures but also provide actionable insights, allowing aerospace engineers to optimize design and ensure compliance with rigorous standards.

Ensure every aerospace component performs flawlessly. Contact LIB industry today to explore our Temperature Humidity Laboratory Climatic Test Chambers. Benefit from:

3-year warranty

Lifetime technical support

Responsive English-speaking service

Customizable testing programs for unique aerospace applications

Equip your lab with testing solutions that guarantee results. Protect your investment, accelerate product development, and deliver reliable aerospace components with confidence.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia