Features and Benefits of UV Exposure Test Machine

1. Accelerated aging testing can simulate the aging effect of materials in natural environments for years within tens or hundreds of hours, accelerating the detection of materials' UV and weather resistance.

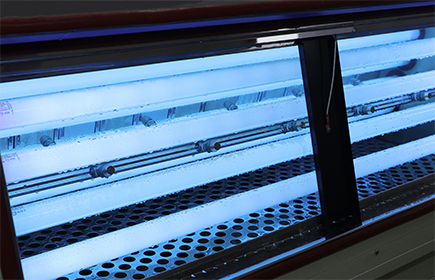

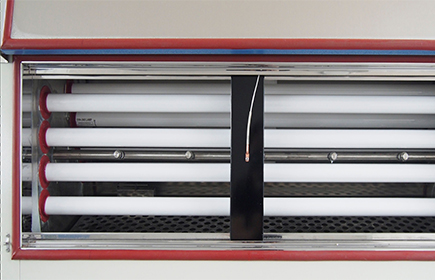

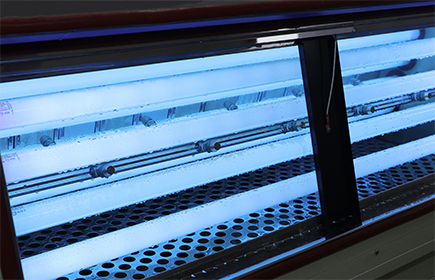

2. The UVA-340 or UVB-313 tubes, and the output wavelengths are concentrated around 340 nm or 313 nm respectively, which complies with standards such as ASTM G154 and ISO 4892-3.

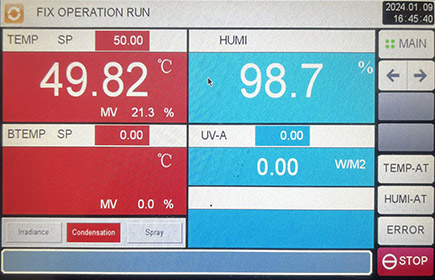

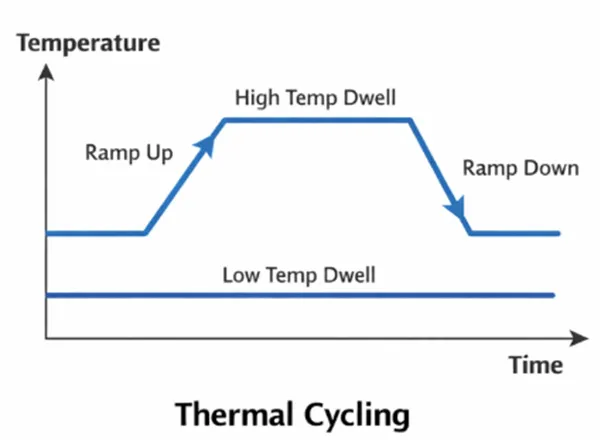

3. The temperature can be controlled. It is also equipped with condensation and water spray functions to simulate the real day-night temperature difference and humidity cycle.

4. Supports light/condensation cycle, effectively simulating the alternating environment of direct sunlight during the day and high humidity condensation at night outdoors, accelerating the detection of surface aging, cracking and fading.

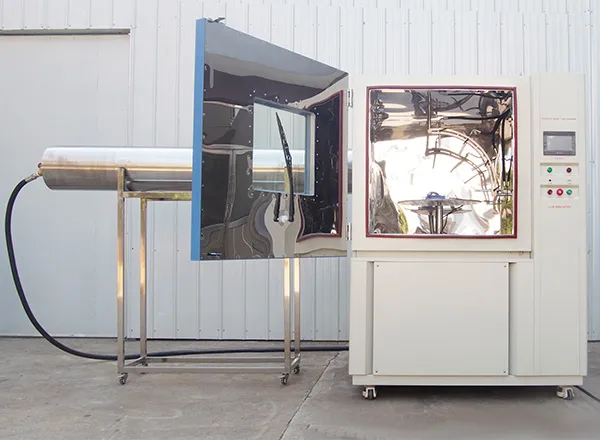

Specifications of UV Exposure Test Machine

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

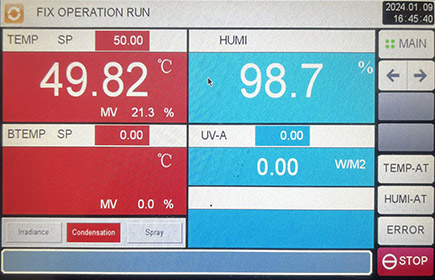

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Details of UV Exposure Test Machine

|

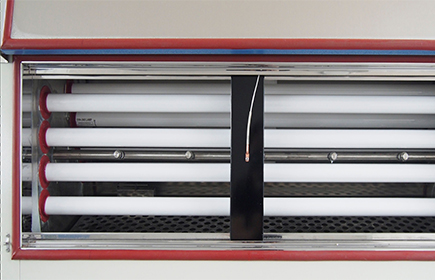

UV tubes | Black Panel |

A combination of 8 QUVA and QUVB tubes.The lifespan is up to 1,600 hours, and the automatic irradiation intensity compensation system can maintain the consistency of light intensity during long-term testing. | Install on the same plane as the sample, ensuring that the measured temperature is representative.It represents the highest temperature that the material surface may reach. Adjust within the range of 35°C to 80°C. |

|  |

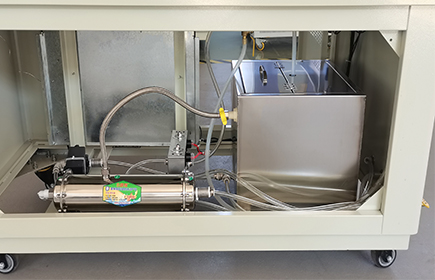

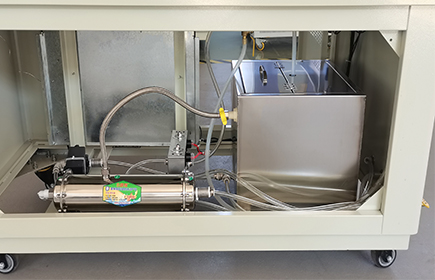

Spray System | Controller |

There are five nozzles on each side, simulating processes such as rainfall and cooling in the natural environment to accelerate the aging of materials in the humid cycle. The spray mode can be set. | The programmable touch screen controller (PLC control) can control and display various parameters in real time, and has an alarm function. |

|  |

Heater Tubes | Water Tank |

Two types of heating tubes: temperature and humidity. The humidity heating tube is circular and placed in water. After heating, it generates steam. The temperature heating tube directly heats the bottom of the workroom. | Serves as the water supply source for the spray system and humidity control. It is a large-capacity water tank made of SUS304 material, equipped with a water circulation system and a water filtration system to prevent nozzle clogging. |

|  |

The LIB UV exposure test machine enjoys a 3-year warranty, lifetime service, 24/7 technical support, and also supports various customizations to provide you with tailor-made solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia