Cyclic Corrosion Testing (abbreviated as CCT) is an environmental simulation testing method widely used in the automotive, aviation, electronics and metal materials industries.

The cyclic corrosion test chamber accelerates the evaluation of the corrosion resistance of products by simulating the periodically changing climatic conditions such as salt spray, dryness, high temperature and high humidity in the natural environment. Temperature and humidity control is one of the most crucial parameters throughout the entire test process, which has a direct impact on the corrosion rate, corrosion morphology, and the repeatability of the test results.

In cyclic corrosion tests, temperature and humidity usually need to be flexibly switched at different stages, for example:·

High-temperature drying stage: 40℃ to 60℃, RH < 30%

Wet and heat stage: 45℃ to 50℃, RH > 95%

Salt spray stage: 35℃±1℃, saturated salt water spray (5% NaCl solution)

An increase in temperature will accelerate corrosion reactions, such as oxidation, chlorination, sulfidation, etc. The increase in humidity is conducive to the formation of a water film on the metal surface by electrolytes, promoting electrochemical reactions. Inaccurate control will lead to distortion of the corrosion rate, and the test will lose its reference value. Therefore, in CCT, the accuracy of temperature and humidity control directly determines the consistency and scientific nature of the test.

Model | SC-010 | SC-016 | SC-020 |

Interior Volume (L) | 780 | 1280 | 1800 |

Temperature Range | +10 ℃ ~ +90 ℃ | ||

Temperature Fluctuation | ± 0.5 ℃ | ||

Temperature Deviation | ± 2.0 ℃ | ||

Humidity Range | 30% ~ 98% RH | ||

Humidity Deviation | + 2%, - 3% | ||

Salt Fog Deposition | 1~2ml / 80cm2 · h | ||

Controller | Programmable color LCD touch screen controller, Ethernet connection | ||

Material | Glass fiber reinforced plastics | ||

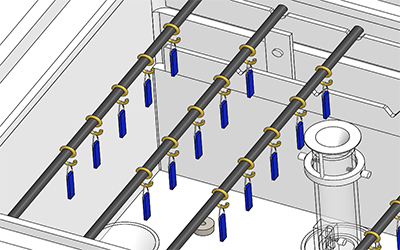

Standard Configuration | 8 round bars | ||

| |||

The LIB cyclic corrosion test chamber meets a number of international standards, such as:

ISO 16701

VDA 233-102

ASTM G85

SAE J2334

High-precision temperature control system: LIB adopts PID intelligent temperature control algorithm, combined with high-sensitivity sensors, to achieve temperature fluctuation control within ±0.5℃, ensuring precise temperature restoration in each cycle stage.

Humidity control system: Equipped with a precise humidity generation and control module, the humidity fluctuation is controlled within ±3%RH, ensuring a true and effective simulation of the natural moisture environment during the humid stage.

Multi-stage automatic programming: The cyclic corrosion test chamber supports the setting and free switching of multiple test programs, automatically achieving seamless transitions between different cycle conditions such as drying, wetting, and salt spray.

Remote monitoring and data recording: Users can connect to the remote control system via a PC for real-time monitoring. All test parameters can be automatically recorded and exported, facilitating quality traceability and analysis.

The accuracy of temperature and humidity control not only determines the reliability of the cyclic corrosion test results, but also directly affects the enterprise's evaluation and improvement strategies for the corrosion resistance performance of the products. Whether it is conventional corrosion testing or customizing complex cycle condition schemes, LIB can provide comprehensive technical support and high-performance equipment solutions.

LIB is specializing in the research, development and manufacturing of environmental reliability test chambers. Its main products include salt spray test chambers, constant temperature and humidity chambers, ultraviolet light aging chambers, thermal shock test chambers, cyclic corrosion test chambers, etc. LIB test chambers are exported to over 60 countries, and are widely used in industries such as automobiles, aerospace, electronics, new materials and coating.

For more information on LIB cyclic corrosion test chamber technical parameters and custom services, please visit the official website: www.libtest.com or email inquiry@libtestchamber.com. LIB look forward to providing you with professional and reliable environmental testing solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia