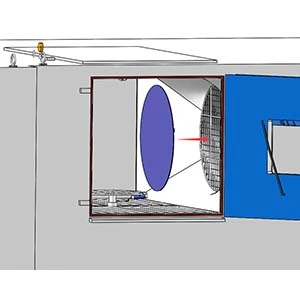

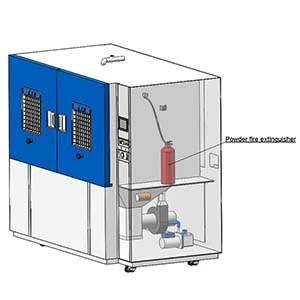

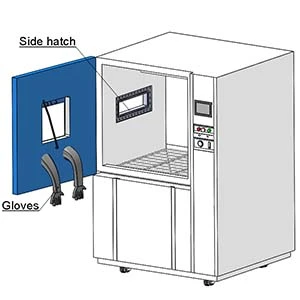

LIB Industry offers a wide range of dust test chambers with different sizes and configurations to meet various test requirements. Our dust test chambers come with precise control for testing products' reliability, safety, and performance under harsh environments. We design and produce dust chambers that comply with international standards to meet all our clients' needs.

LIB dust sand test chambers cover many types, including IEC60529 standard sand and dust chambers, MIL-STD-810 blowing sand and dust chambers and blowing sand test chamber. Contact us to get your competitive factory price!

How Do You Maintain And Calibrate A Dust Test Chamber?

Maintenance:

1. Always follow the dust chamber manufacturer's instructions for maintenance and cleaning.

2. Inspect the chamber regularly for any signs of wear, damage, or malfunction. Fix any issues promptly.

3. Clean the chamber regularly, including the dust collection tray, by vacuuming and wiping surfaces with a damp cloth.

4. Replace any worn-out parts such as the filter, fan blades, or seals.

5. Monitor the temperature and humidity levels regularly. If they are outside the recommended range, adjust them accordingly.

6. Avoid overfilling the dust collection tray to prevent premature wear of the fan motor.

Calibration:

1. Follow the dust chamber supplier's instructions for calibration.

2. Before calibration, ensure that the chamber is clean and free of dust or debris.

3. Perform the calibration using a calibrated reference instrument that measures the concentration of dust particles.

4. Measure and record the concentration of dust particles at various levels of airflow. Adjust the chamber airflow as needed.

5. Perform a validation test to confirm the correct calibration of the chamber.

6. Repeat the calibration process at least once a year or according to the manufacturer's recommendations.

7. Document all calibration procedures and results.

How Long Does A Typical Dust Test Chamber Last, And What Factors Affect Its Service Life?

The lifespan of a dust test chamber can vary depending on several factors, including the quality of the manufacturing, usage and maintenance, and the materials used. A well-made and maintained chamber can last for up to 10 years or more.

Some of the factors that affect the service life of a dust test chamber include:

1. Frequency of use: The more the chamber is used, the quicker it will wear down.

2. Type of dust: Some types of dust are more abrasive than others and can wear down the chamber faster.

3. Humidity levels: The higher the humidity levels, the greater the risk of rust and corrosion.

4. Temperature: Excessive temperature fluctuations can affect the mechanical and electronic components of the chamber.

5. Quality of materials: High-quality materials will generally result in a longer lifespan for the chamber.

6. Maintenance: Regular test chamber maintenance and cleaning can prolong the lifespan of the chamber.

7. Frequency of repairs: The more often the chamber requires repairs, the quicker it will wear down.

8. Operating conditions: Extreme weather or other environmental factors can potentially shorten the lifespan of the chamber.

It is important to note that the frequency and quality of maintenance significantly affect the lifespan of a dust test chamber. Regular maintenance, such as replacing worn-out parts and cleaning the chamber, can greatly extend its service life.

Why Choose LIB As Dust Test Chamber Supplier?

Xi’an LIB Industry is one of professional environmental chamber manufacturers with a unique brand, and also is the market leader in production, design and sales. LIB will provide the suitable environmental chambers and solutions according to your requirements. Standard models or customized models are all available.

Arrange production according to the designed parameters. After the test chamber is completed, we conduct performance testing, functional inspection, commissioning test, calibration, and issue reports on every step to guarantee quality.

LIB’s professional transportation team carries out international transportation for you, our complete transportation system can achieve door-to-door services. LIB will send professional engineers to provide on-site service for installation services and training.