Waterproof performance is a critical reliability factor for modern consumer electronics, home appliances, IoT devices, and outdoor equipment.

Failures caused by water ingress frequently lead to customer complaints, product returns, and safety risks.

IPX4 waterproof testing provides the baseline protection required for products exposed to daily splashes from any direction.

For many common industrial products, such as electric toothbrushes and Bluetooth headsets, the general waterproof requirements are IPX4, and quality inspector need to use ipx4 waterproof test equipment with IEC 60529 compliance to check whether their waterproof performance is qualified before they leave the factory.

|

|

The IP Code (Ingress Protection Code) is an international standard (IEC 60529) that measures the level of protection provided against the intrusion of solid objects (e.g., dust) and liquids (e.g., water) in electrical enclosures or electronic devices, such as smartphones, tablets, and wearables.

The IP code consists of two digits that indicate the level of protection. The first digit denotes the protection against solid objects, and the second digit denotes the protection against liquids. For example, IP68 means the device is dust tight and can be submerged in water up to a certain depth and duration. The IP code is important for ensuring the durability and reliability of electronic devices in different environments.

IP Rating | Degree of Protection Against Solid Foreign Objects | Degree of Protection Against Water |

IP03 | Not Protected | Spraying water |

IP13 | Solid object >50 mm | Spraying water |

IP23 | Solid object >12.5 mm | Spraying water |

IP33 | Solid object>2.5 mm | Spraying water |

IP43 | Solid object>1 mm | Spraying water |

IP53 | Dust protected | Spraying water |

IP63 | Dust tight | Spraying water |

IP04 | Not Protected | Splashing water |

IP14 | Solid object >50 mm | Splashing water |

IP24 | Solid object >12.5 mm | Splashing water |

IP34 | Solid object>2.5 mm | Splashing water |

IP44 | Solid object>1 mm | Splashing water |

IP54 | Dust protected | Splashing water |

IP64 | Dust tight | Splashing water |

IPX4 verifies a device’s ability to withstand multi‑angle splashing water.

Engineering requirements include:

- Flow rate: 10 L/min

- Pressure: 80–100 kPa

- Duration: ≥5 minutes

- Full-direction exposure via oscillating tube + rotating turntable

Critical challenges:

- Maintaining stable water flow

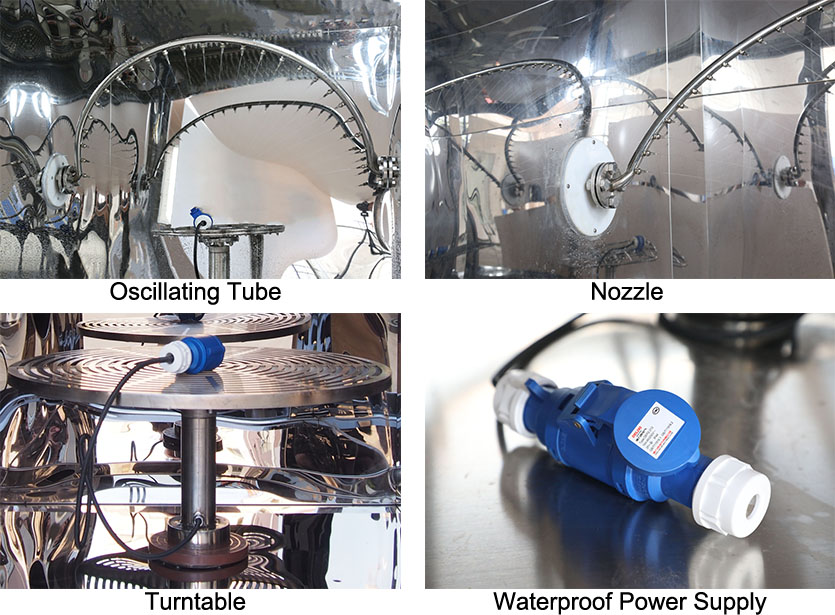

- Ensuring perfect 0.4 mm spray-hole uniformity

- Preventing nozzle clogging

- Achieving consistent oscillation angle

This is exactly where professional equipment becomes essential—not just any spray system can meet these standards.

LIB industry builds IPX4 test systems designed for reliability, repeatability, and strict IEC compliance.

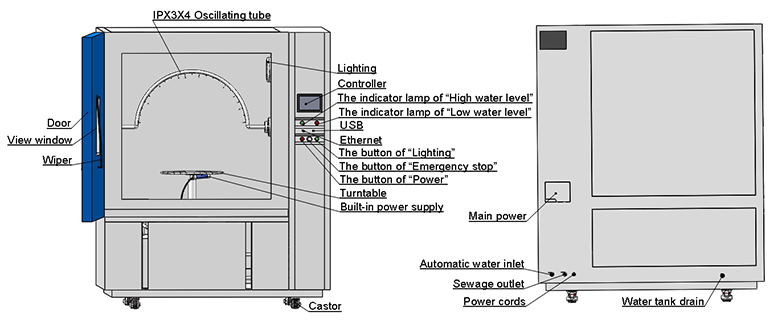

Key engineering-driven features include:

0–180° programmable swing, stable servo-driven motion

0.4 mm nozzle holes with 50 mm spacing for consistent water distribution

Accurate 10 L/min flow, 80–100 kPa water pressure

1 rpm adjustable speed, supports powered samples

Prevents nozzle clogging and maintains long-term stability

Model | R-800C | R-1200C |

Useful Volume (L) | 810 | 2400 |

Oscillating Tube Radius | 400mm | 600mm |

Spraying Hole Diameter | φ0.4mm | |

Hole Spacing | 50 mm | |

Swing Angle of Oscillating Tube | 0 ~ ±180° (Adjustable) | |

Turntable Rotation Speed | 1r/min (Adjustable speed) | |

Water Pressure Control | Flow meter | |

Controller | Programmable color LCD touch screen controller, Ethernet connection | |

Water supply system | Water tank, booster pump, Automatic water supply, Water purification system | |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection | |

Exterior Material | Steel Plate with protective coating | |

Interior Material | SUS304 stainless steel | |

Observation Window | Double layer insulating glass with wiper | |

| ||

These features ensure repeatable, lab-quality waterproof testing for R&D and mass production.

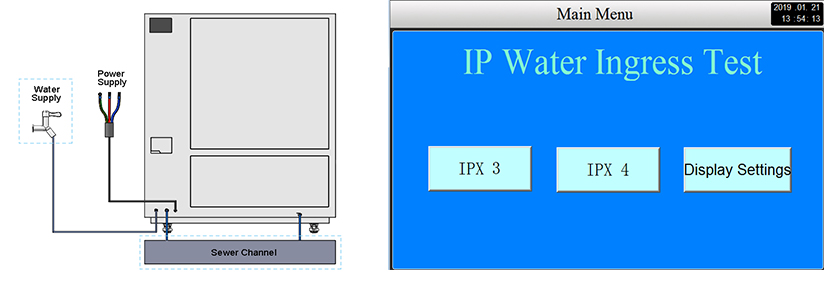

1. Connect 220V power supply and water inlet. The system automatically fills the tank.

2. Install the sample securely at the center of the turntable. Connect internal power if required.

3. Select IPX4 mode. Configure oscillation angle, test duration, and flow rate.

4. Verify nozzle holes and replace any blocked or deformed needles.

5. Adjust the flow meter to achieve 10 L/min and 80–100 kPa.

6. Start the test. The system will automatically oscillate, rotate, and complete the cycle.

7. Inspect the device for water ingress or functional degradation after the test.

LIB industry’s controller simplifies parameter setting and ensures accurate and repeatable test execution.

Choosing LIB industry means choosing reliability, compliance, and long-term performance.

• High-precision mechanical design for stable waterproof testing

• Automatic filtration prevents nozzle clogging

• Customized fixtures, tube sizes, and sample mounts

• Professional engineering guidance for test method optimization

Backed by LIB’s industry-leading support:

3-Year Warranty

Lifetime Technical Service

1–3 Hour Fast Response

7–15 Day Fast Delivery

Remote or Onsite Installation & Training

If your R&D lab or production facility needs stable, accurate, and compliant IPX4 testing, LIB industry provides proven professional solutions.Contact us at inquiry@libtestchamber.com for more specs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia