Mini Temperature Chamber Features and Benefits

1. Wide Temperature Range Options

To meet different testing needs, the Mini Temperature Chamber is available in three temperature configurations:

Type A: -20°C to +150°C — standard laboratory temperature tests

Type B: -40°C to +150°C — electronics and automotive components

Type C: -70°C to +150°C — extreme environment and aerospace testing

This flexible configuration ensures compatibility with a wide range of test standards and applications.

2. Accurate and Uniform Temperature Control

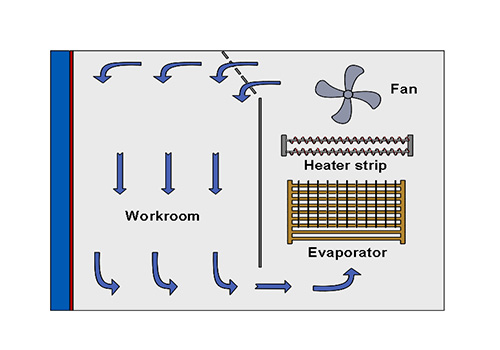

Precise control guarantees that all samples inside the chamber are exposed to a consistent thermal environment, ensuring repeatable and reliable test results.

3. Efficient Heating and Cooling

Heating rate: 3°C/min

Cooling rate: 1°C/min

Fast temperature response improves testing efficiency and reduces overall test cycle time.

4. Intelligent Control System

The Mini Temperature Chamber is equipped with a programmable color LCD touch screen controller that combines accuracy with ease of operation.

Key features include:

Clear graphical user interface

Precise temperature setting and real-time monitoring

Programmable temperature profiles and cycles

Ethernet connection for data communication and system integration

The controller allows users to easily perform both routine tests and complex temperature cycling programs.

Mini Temperature Chamber Specifications

Model | TH-50 | TH-80 |

Internal Dimension (mm) | 320*350*450 | 400*400*500 |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

Controller | Programmable color LCD touch screen controller Ethernet connection |

Safety Device | Humidifier Dry-combustion protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure protection; Water Shortage Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

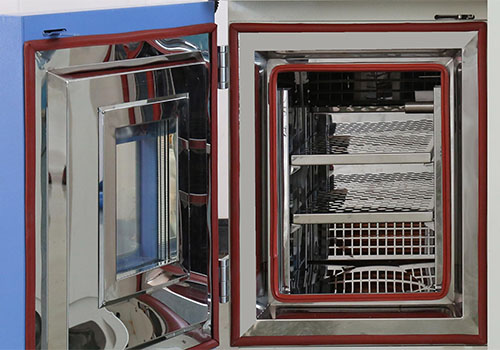

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

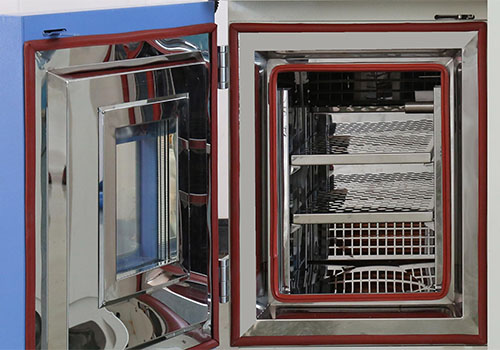

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

Weight | 190kgs | 220kgs |

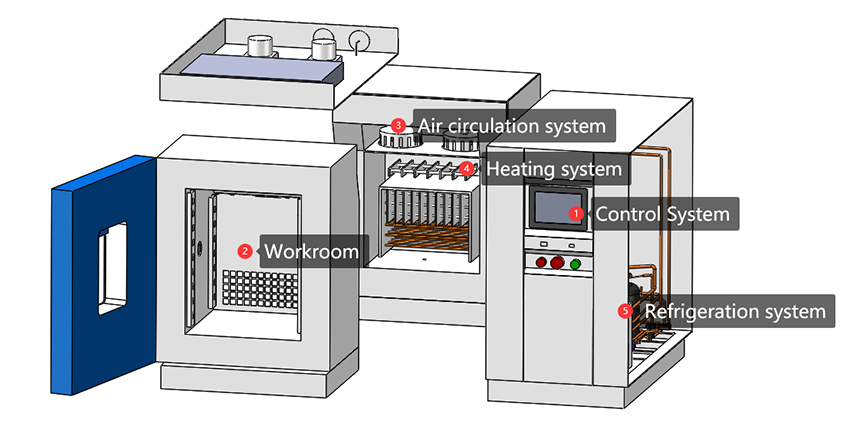

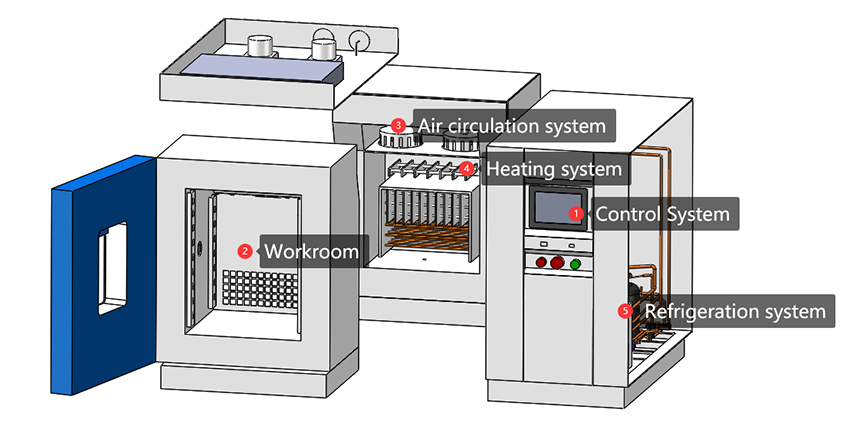

Details of Mini Temperature Chamber

|

|

|

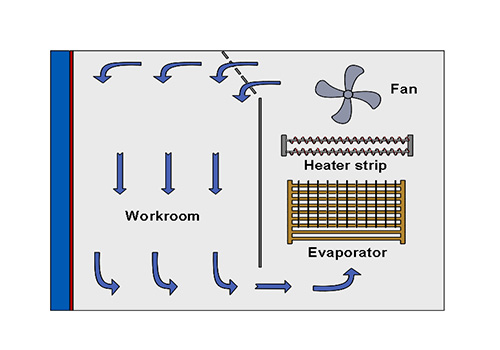

Industrial-Grade Chamber StructureThe Mini Temperature Chamber features a robust exterior made of coated steel plate and a corrosion-resistant SUS304 stainless steel interior. This structure ensures long-term durability under repeated thermal cycling, while resisting corrosion and deformation during extended testing. | Optimized Air Circulation SystemThe Mini Temperature Chamber adopts a forced air circulation design to ensure efficient airflow distribution inside the workspace. This structure reduces temperature layering and helps the chamber reach set values faster while maintaining internal consistency. |

|

|

Standardized Test Interface & Sample AccessThe chamber is equipped with a standard cable access port (Φ50 mm) and adjustable shelves, allowing flexible sensor wiring and sample placement. This design supports a wide variety of test setups without additional customization. | Reliable Low-Temperature Refrigeration PerformanceDesigned specifically for extreme temperature testing, the refrigeration system maintains stable cooling capacity even at -70°C, supporting long-duration and cyclic tests without performance degradation. |

Typical Applications

Electronics Industry

Temperature stress testing of PCBs, IC chips, sensors, capacitors, and electronic components to verify performance stability under extreme temperatures.

Automotive Industry

Thermal tolerance testing for automotive sensors, batteries, and electronic control units to ensure reliability in harsh environments.

Medical & Pharmaceutical Field

Evaluation of temperature stability and storage conditions for pharmaceutical and biological products.

Materials Research

Assessment of thermal and mechanical behavior of plastics, rubber, metals, and composite materials under temperature variation.

Aerospace Industry

Simulation of high-altitude low-temperature and high-temperature environments for aerospace components to ensure safety and reliability.

Talk to a Temperature Testing Expert

With LIB industry, you get more than equipment.We provide pre-sales consultation, on-site installation and commissioning, operator training, a 3-year warranty, lifelong technical support, and responsive English-speaking service for worry-free laboratory operation.

Get Technical Support & Quote inquiry@libtestchamber.com

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia