Ensuring cable and material durability under ozone exposure is a critical challenge for manufacturers. Rubber, plastic, and composite cable jackets can degrade over time due to environmental stress, leading to premature failures or costly recalls. Traditional outdoor aging tests can take years, while inaccurate lab simulations often produce misleading results.

The solution lies in LIB industry ozone test chamber technology, engineered to replicate real-world conditions precisely, safely, and efficiently.

LIB industry ozone aging testing machines combine precise environmental control, versatile sample mounting, and robust safety features. Engineers can adjust ozone concentrations from 1–1000 PPHM, temperatures from 0–100 °C, and humidity between 30–98 % RH, enabling accelerated testing aligned with IEC 60068-2-42, ISO 1431, ASTM 1149, IEC 60903, and Volkswagen PV3305 standards.

These capabilities ensure that every ozone test chamber delivers reliable, repeatable, and internationally recognized results, reducing development risks and speeding up product validation.

|

|

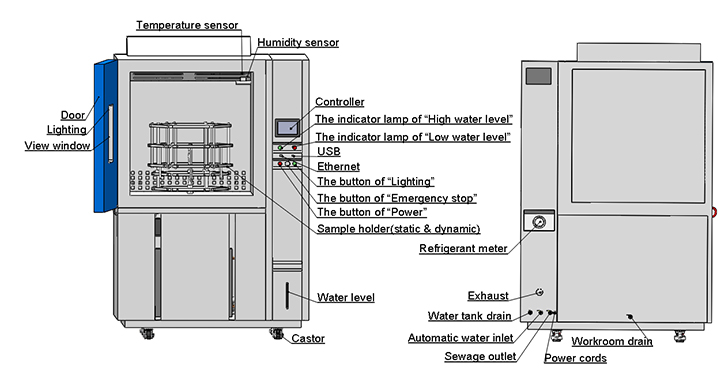

Key Parameters:

- Temperature Range: 0–100 °C | Humidity Range: 30–98 % RH

- Ozone Concentration: 1–1000 PPHM | Sample Holder Rotation: 0–10 r/min

- Clamps Tensile Stretch: 5–35 % | Cooling Rate: Ambient → 0 °C within 20 min

- Controller: Programmable color LCD touchscreen, Ethernet, PC link

LIB ozone test chambers replicate environmental aging with remarkable precision. For instance, a rubber cable jacket can be exposed to 2 ppm ozone (±15 %), 40 °C (±3 °C), and 55 % RH (±5 %) for 48 hours, simulating years of real-world outdoor conditions.

Cables can be mounted on static clamps or rotating holders with controlled elongation of 5–35 %, reproducing bending, twisting, and stretching during actual service. Temperature, humidity, and ozone levels are continuously monitored using a PID touchscreen controller to ensure highly repeatable cycles. Silent-discharge ozone generators combined with activated carbon filtration neutralize residual ozone, maintaining operator safety and meeting ISO 14001 environmental standards.

Every cable type faces unique challenges during ozone exposure and mechanical stress. LIB industry ozone test chambers and ozone aging testing machines provide flexible, fully customizable solutions to replicate real-world conditions across multiple industries, including automotive, power, telecommunications, and industrial cable manufacturing.

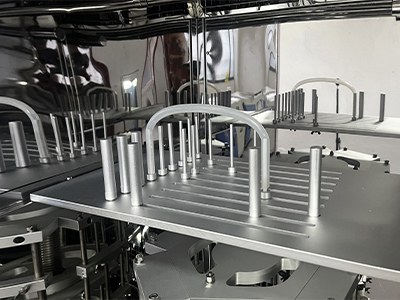

Adjustable core spindles, dual-layer racks, and dynamic/static combination holders allow precise elongation, rotation, or bending to match specific testing standards.

|

|

|

Ozone test chambers are available in multiple sizes with tailored airflow, tensile, and rotation rates to meet diverse cable geometries and mechanical requirements.

Beyond ozone, LIB industry also provides noxious gas test chambers, enabling comprehensive environmental testing for components that must endure harsh chemical conditions.

With this level of customization, manufacturers can trust that every test performed in a LIB ozone test chamber or ozone aging testing machine delivers repeatable, standards-compliant, and realistic results, shortening development cycles and minimizing the risk of field failures.

Routine maintenance—including activated carbon filter replacement, ozone sensor verification, and seal inspection every 6–12 months—ensures long-term performance. Annual calibration guarantees compliance with international standards, while pre-test exhaust system checks protect operators.

If a ozone test chamber cannot be repaired remotely, a replacement is shipped free of charge, ensuring uninterrupted testing.

Across automotive, energy, telecommunications, and industrial cable applications, LIB ozone test chambers and ozone aging testing machines help manufacturers detect material weaknesses early, optimize designs, and accelerate product launches with confidence.

Fast, tailored solutions: Share your testing requirements and receive a fully customized plan with an exclusive quotation within 1–3 hours.

Proven expertise: Benefit from over 16 years of experience and extensive inventory ready to meet your needs.

Global support: Access worldwide service points, 3-year warranty, lifetime maintenance, and 24/7 technical assistance.

Choose LIB industry for precise, standards-compliant ozone test chamber and ozone aging testing machine solutions that keep your development on schedule and your products safe.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia