The ASTM B117 salt spray environmental chamber is a widely used method to evaluate the corrosion resistance of coatings, electroplating, and surface treatments under accelerated conditions. It is especially common in automotive, electronics, aerospace, and construction industries for quality assurance and material comparison.

ASTM B117, titled "Standard Practice for Operating Salt Spray (Fog) Apparatus," defines the operational parameters of a salt spray test chamber. It does not define performance limits but ensures a standardized environment for comparing corrosion behavior.

The core of the test involves spraying a 5% sodium chloride (NaCl) solution into a closed chamber at 35°C, creating a consistent salt fog that settles on the specimens. This simulates long-term environmental exposure in a much shorter time.

Coatings like paint, powder, and electroplated finishes (e.g., zinc, chrome, nickel) are applied to protect metal substrates from corrosion. The B117 test:

Accelerates corrosion to evaluate protective quality.

Compares different coatings under identical conditions.

Detects weak spots like cracks, pinholes, or poor adhesion.

Remove oils and dirt using alcohol or acetone.

Cover non-test areas to isolate results.

Place samples at a 15° to 30° angle from vertical to avoid salt buildup.

Use corrosion-proof tags or etching.

Parameter | Value |

Salt Solution | 5% NaCl |

pH Range | 6.5 – 7.2 |

Temperature | 35 ±1°C |

Fog Collection Rate | 1 – 2 mL/h per 80 cm² |

Test Duration | 24 to 1000+ hours depending on spec |

After testing, samples are evaluated by:

Look for rust, blisters, peeling, or discoloration.

Measure creep distance from a scratch line on coated panels (per ASTM D1654).

Use ASTM D610 for corrosion coverage scoring.

Optional, for detailed failure analysis.

There is no pass/fail in ASTM B117; results are interpreted using customer or industry-specific requirements.

Automotive: Testing painted panels and electroplated parts (e.g., zinc-coated bolts).

Electronics: Verifying corrosion resistance of coated connectors.

Marine: Simulating saltwater exposure for metal housings and fasteners.

Construction: Assessing powder-coated aluminum and galvanized steel.

LIB’s salt spray chambers are designed for precision, repeatability, and durability:

Stable Temperature & pH: Controlled with advanced PID controllers.

Uniform Fog Distribution: Special atomizers and airflow design ensure consistency.

Corrosion-Resistant Build: PVC/PP-lined interiors withstand long tests.

Flexible Sizes: From benchtop to walk-in models for large parts.

Optional Remote Control: USB and Ethernet monitoring available.

ASTM B117 does not replicate outdoor weathering, so combine with cyclic corrosion or field tests when needed.

Use control samples for comparison.

Always follow chamber calibration and maintenance guidelines

ASTM B117 remains a simple, effective, and standardized way to evaluate the corrosion resistance of coatings and electroplated materials. When performed in a well-maintained chamber like LIB’s, it offers valuable insight into material performance under harsh conditions, aiding both product development and quality assurance.

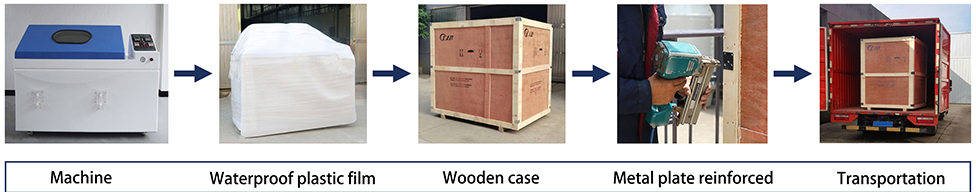

LIB offers a wide range of standard models of salt spray environmental test chambers, as well as three series of salt spray test chambers. At the same time, on this basis, LIB can also customize salt spray test chambers according to your special testing requirements. Welcome to leave your requirements.

LIB will provide you with the corresponding quotations and the best test equipment solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia