Ensuring the long-term performance of high-performance solar panels requires rigorous aging tests under a variety of environmental conditions. Over time, exposure to heat, humidity, freezing temperatures, and sunlight can degrade materials such as EVA encapsulants, back sheets, glass, and soldered connections, ultimately affecting energy output and reliability.

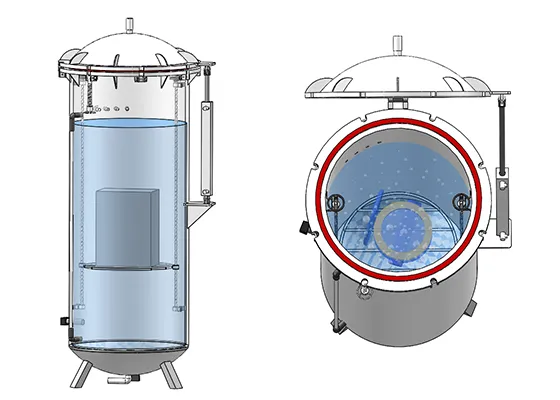

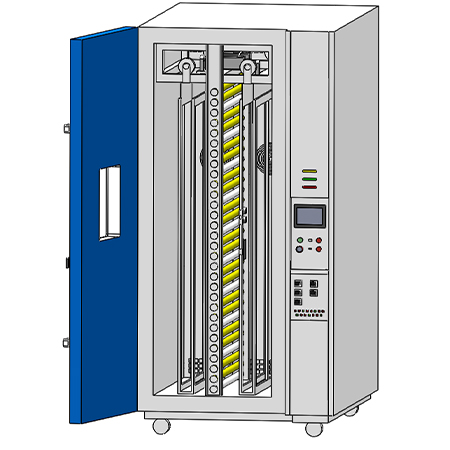

To accurately evaluate solar panel durability, LIB industry offers two specialized solutions: the PV Environmental Chamber for thermal, humidity, and freeze testing, and the UV Preconditioning Chamber for simulating long-term sunlight exposure. These high-precision instruments allow manufacturers and testing laboratories to perform accelerated aging tests in compliance with international standards like IEC 61215, IEC 61730, and ASTM G154.

|  |

| PV Environmental Chamber | UV Preconditioning Chamber |

By utilizing these chambers, solar panels can be reliably tested for long-term performance, providing insights for product optimization and quality assurance.

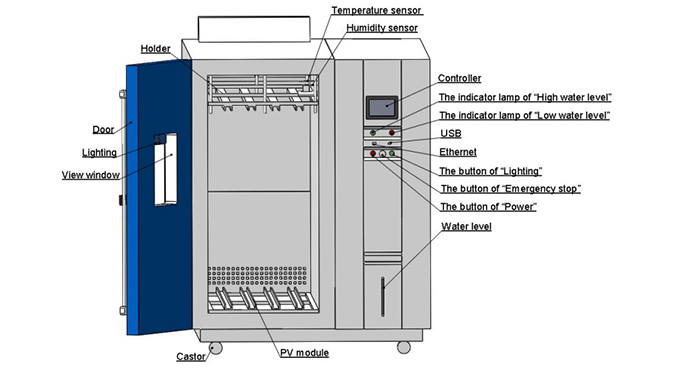

The LIB industry PV Environmental Chamber is designed to perform multiple aging tests within one system, supporting large panels and multiple samples simultaneously. It complies with IEC 61215 and IEC 61730 standards and ensures accurate results for long-term durability evaluation.

Flexible Mounting: Panels can be installed vertically or at a tilt.

Customizable Size Support: Handles panels up to 1.5 m × 2.5 m.

Multiple Panel Capacity: Supports testing of several panels simultaneously.

Adjustable Racks: Rack height and spacing can be modified for optimal positioning.

Optional Roller Racks: Simplifies handling of heavier modules.

| |

|

These features make the chamber particularly suited for solar panel testing, providing even exposure and reliable results without occupying excessive space.

Purpose:The Damp Heat Test simulates prolonged exposure to high temperature and high humidity, accelerating material degradation, EVA yellowing, back sheet delamination, and solder joint oxidation.

Testing Conditions:

Temperature: 85 °C

Relative Humidity: 85% RH

Duration: 1000 hours (or as required by IEC 61215)

LIB Industry Features and Advantages:

Temperature control precision: ±0.5 °C

Humidity control precision: ±2% RH

Uniform distribution ensures consistent testing conditions

Automatic data logging and remote monitoring

Supports large-format panels

Maintains consistent conditions for extended durations

Integrated sensors and monitoring enable precise measurement

Temperature Range | -60℃ ~ +100 ℃ | |

Temperature Fluctuation | ± 0.5 ℃ | |

Temperature Deviation | ± 2.0 ℃ | |

Humidity Range | 20% ~ 98% RH | |

Humidity Deviation | ± 2.5% RH | |

Expected Outcomes:

EVA yellowing and delamination

Back sheet degradation

Oxidation of solder joints

Detailed reports for lifetime prediction and optimization

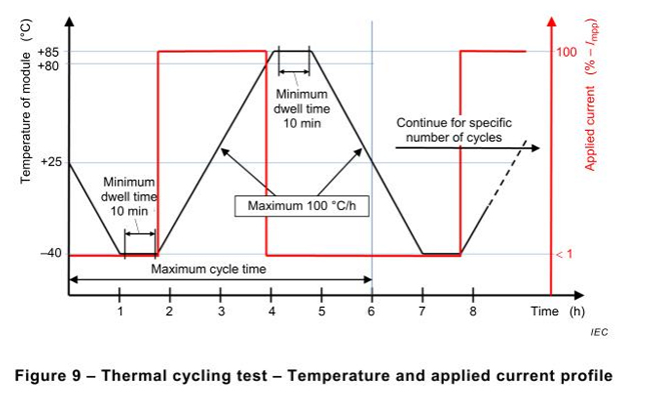

Purpose:The Thermal Cycling Test evaluates the mechanical stress caused by temperature fluctuations, which can lead to cracking, solder joint failures, and delamination.

Testing Conditions:

Temperature range: -40 °C to +85 °C

Number of cycles: 200–600 (per IEC 61215)

Heating/cooling rate: 2–5 °C/min

LIB Industry Features and Advantages:

Precise temperature cycling with uniform distribution

Multi-panel simultaneous testing

Built-in safety: anti-condensation, overheat protection

Automatic data recording

Programmable Cycle Patterns: Mimic real-world temperature variations

Visual & Digital Monitoring: Observe panel responses throughout testing

Temperature Change Rate | 1 ~ 3.4℃ / Min | |

Expected Outcomes:

Cracks in glass or encapsulant

Solder joint fatigue or failure

EVA delamination or panel warping

Comprehensive data for mechanical stability

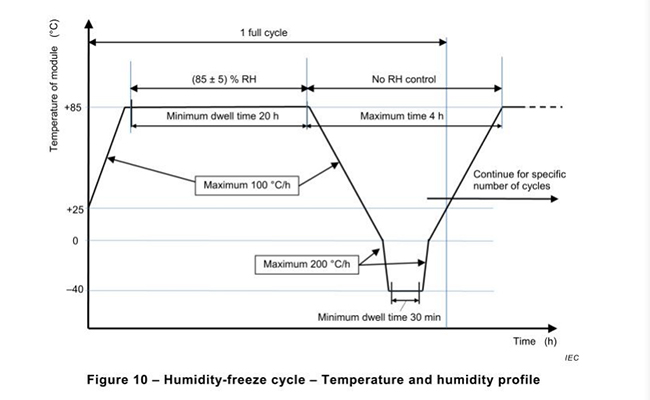

Purpose:Simulates extreme cold conditions to assess solar panel encapsulation stability. Moisture freezing can cause material cracking or interface separation.

Testing Conditions:

Humid phase: 85 °C / 85% RH, 1000 hours

Freeze phase: -40 °C, maintained for several hours

Multiple alternating cycles

LIB Industry Features and Advantages:

Combines humid-heat and freeze testing

Anti-condensation design protects panels and equipment

Automated data recording

Supports large panels and multiple samples

Precise Transition Control: Smoothly alternates between temperature and humidity extremes

Early Failure Detection: Monitors material stress in real-time

Enhanced Panel Safety: Reduces risk of panel damage during testing

Temperature Range | -60℃ ~ +100 ℃ | |

Temperature Fluctuation | ± 0.5 ℃ | |

Temperature Deviation | ± 2.0 ℃ | |

Humidity Range | 20% ~ 98% RH | |

Humidity Deviation | ± 2.5% RH | |

Expected Outcomes:

EVA cracking or embrittlement

Glass breakage or warping

Back sheet delamination or adhesive failure

Detailed analysis for product improvement

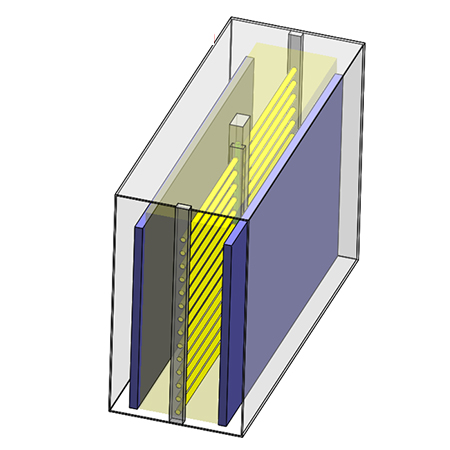

Long-term sunlight exposure can degrade EVA, back sheets, and overall panel integrity. LIB industry’s UV Preconditioning Chamber simulates solar radiation, providing controlled accelerated UV aging tests for realistic longevity assessment.

UVA and UVB lamps arranged for uniform irradiation

30 lamps total with optimized UVA lamps incorporating UVB components to meet IEC 61215

Temperature: 60–70 °C

Adjustable UV intensity and cycle duration

Uniform UV exposure across panels

Adjustable intensity for different climates

Integrated cooling and humidity system

Compliant with ASTM G154 and IEC 61215 preconditioning standards

Specimen Capacity | 2/4/6/... Pieces |

Irradiation Source | Fluorescent UVA lamps (20 pieces) and UVB lamps (10 pieces) |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Bandwidth | UVC: (< 0.1%) UVB: (3% to 10% of total UV) UVA: (90% to 97% of total UV) |

Irradiance Control | ●The wavelength of 280 nm - 320 nm:7.5 k Wh/m2 ●The wavelength of 320 nm - 400 nm:15 k Wh/m2 ●Maximum Irradiance in the UV range: < 250 W/m2 |

Controller | Programmable color LCD touch screen controller |

|  |

EVA yellowing and embrittlement

Back sheet degradation

Adhesive and lamination failures

Provides preconditioned panels for subsequent Damp Heat, Thermal Cycling, and Humidity Freeze tests

Advanced aging tests are essential for ensuring long-term performance, reliability, and safety of high-performance solar panels. LIB industry’s PV Environmental Chamber and UV Preconditioning Chamber allow comprehensive, precise testing, including damp heat, thermal cycling, humidity freeze, and UV preconditioning.

These chambers enable multi-panel testing, automated data collection, and compliance with international standards, giving manufacturers confidence in producing durable, high-quality solar panels.

Contact LIB industry today inquiry@libtestchamber.com to customize a complete solar panel aging test solution tailored to your products.

3-Year Warranty | Lifetime Technical Support | Rapid Engineering Response

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia