Dust testing is a crucial step in verifying the dust-proof capability of products, and it is particularly valued in fields such as automotive electronics, communication equipment, and outdoor instruments. The air circulation system determines the uniformity of dust suspension and distribution and is the core for reproducing the real environment.

With years of R&D experience, the LIB dust test chamber has developed an efficient and stable air circulation solution, providing customers with reliable, repeatable and precise testing conditions.

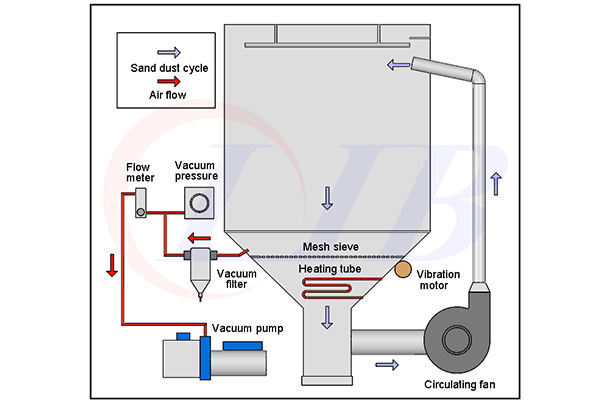

Design highlights: A closed vertical circulation structure is adopted, with top air supply and bottom air return. The air duct design is optimized to ensure that the wind speed in the test area is stable within the range of 1.5-3.5 m/s, and the difference between the center and the edge is ≤±0.2 m/s.

Fan:

Driven by a brushless DC motor, the air volume is adjustable from 0.5 to 10 m³/min, the air pressure is approximately 800 to 1000 Pa.

Powder Feeding Mechanism:

Quantitative feeding combined with stable airflow enables the setting of dust concentration from 2kg to 4kg /m³, and is controlled by PLC closed-loop.

Intelligent Control:

Real-time display on the PLC touch screen, program import/export; Test programs such as IEC 60068-2-68 and IEC 60529 can be preset.

Filtration and Safety:

Dust screen design + Vacuum Filtration design; Equipped with explosion-proof pressure relief, static grounding and abnormal fan alarm, it ensures long-term stable operation.

Both internal and external tests and third-party verification show that the LIB dust test chamber can achieve a highly uniform suspension environment in a larger working chamber (800L - 2000L), making it suitable for long-term aging and high-level dust-proof tests.LIB also supply free talcum powder.

Functional features: Supports modes such as suspended dust blowing and settled dust, and can be linked for testing in combination with temperature (RT~+50℃ or customized wide temperature range).

Typical parameters:

Inner chamber volume: 800L / 1000L / 1500L/2000L (or customized);

Wind speed: 1.5-3.5 m/s Dust concentration: 2KG - 4KG/m³

Control accuracy: Wind speed ±0.2 m/s, concentration fluctuation ≤±5%;

Standard support: Compatible with IEC 60068-2-68 (suspended dust), IEC 60529 IP5X/IP6X deposition test, GB/T equivalent standards.

Typical scenarios: Automotive ECUs, sensor housings, communication chassis, outdoor equipment and other products that need to pass dust-proof/sand-resistant certifications can achieve one-stop environmental testing.

In addition to dust testing, the environmental reliability of products often also involves challenges from multiple factors such as temperature, humidity, water, light and gas. As a professional manufacturer of environmental testing equipment, LIB offers a complete solution ranging from single to compound testing, helping users build an integrated testing platform that complies with international standards.

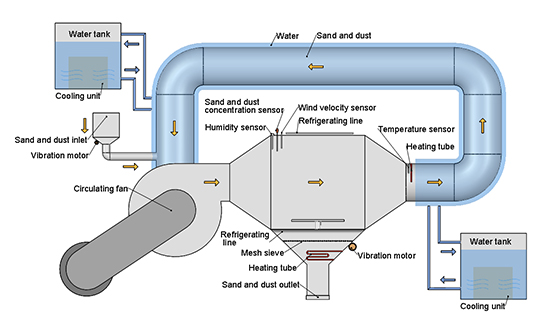

For industries such as military industry, aviation and high-end automotive electronics, MIL-STD-810H imposes stricter requirements on the particle size, wind speed, concentration and temperature of sand and dust.

The LIB MIL-STD-810H dust test chamber has been comprehensively strengthened in terms of structural sealing, air flow intensity, sand particle control and the automation of test procedures. Typical parameters such as sand particle size 150-850μm, high wind speeds 1.5-8.9m/s and 18.0-29.0m/s respectively for dust and sand, and concentration are adjustable to ensure the test accuracy and stability.

Corresponding to the dust test is a comprehensive assessment of the equipment's resistance to water invasion. LIB offers a complete set of waterproof testing equipment ranging from IPX1 to IPX9K, covering testing conditions such as vertical dripping, swing pipe rain, strong water jet, and high-temperature and high-pressure steam water. All models comply with standards such as IEC 60529 and ISO 20653, and can be flexibly configured for flow rate, pressure, temperature and Angle. They are often used for certification and testing of automotive lamps, electronic housings and outdoor security equipment.

For users who need more complex test solutions, LIB also provides the following composable devices:

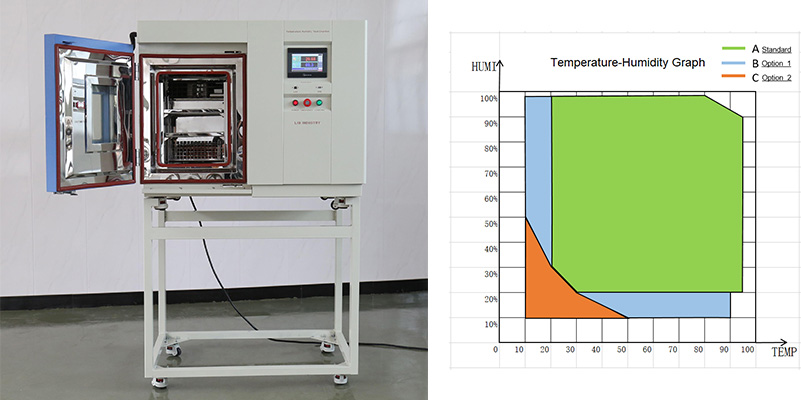

Temperature and humidity chamber: Temperature control accuracy ±0.5℃, humidity range 20~98%RH, supporting long-term aging and high-humidity penetration testing.

Thermal test chamber : Temperature change rate 5~15℃/min, suitable for thermal stress assessment of components;

Xenon /UV weathering chamber: Simulates the full-spectrum natural aging environment, and can customize the lighting, spray, and cycle times.

Ozone/Noxious gas test chamber: Supports precise control of the concentration of corrosive gases such as O₃, SO₂, and NO₂, and is suitable for corrosion resistance tests of seals, coatings, metal protection, etc.

These test chambers share a unified control logic and data interface with LIB's dust test chambers, facilitating customers to establish a standardized testing system and achieve comprehensive coverage of environmental stress and maximize testing efficiency.

LIB INDUSTRY is always committed to providing users with solutions that are not limited to single testing, but to building an environmental testing ecosystem that takes technology as the core, standards as the criterion, and customer needs as the orientation. Through multi-scenario linkage test platforms such as sand and dust, rain, temperature and humidity, light aging, and corrosion, LIB provides comprehensive reliability verification support for various industries.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia