Key Performance Advantages of UV Preconditioning Test Chamber for Solar Panels

1. Solar-Relevant UV Spectrum Composition

The irradiation system delivers a UV spectrum dominated by UVA (≈90–97%), with controlled UVB contribution (≈3–10%) and negligible UVC content (<0.1%), closely matching natural solar exposure conditions.

2. Energy-Based UV Dose Control

UV preconditioning is governed by cumulative energy targets, such as defined exposure levels in the 280–320 nm and 320–400 nm bands, ensuring consistent material stress across different test batches.

3. Independent Thermal & BPT Regulation

Chamber air temperature (ambient to 90 °C, ±2 °C) and Black Panel Temperature are regulated independently, preventing thermal coupling from distorting pure UV aging mechanisms.

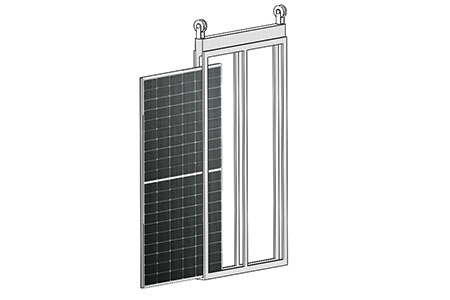

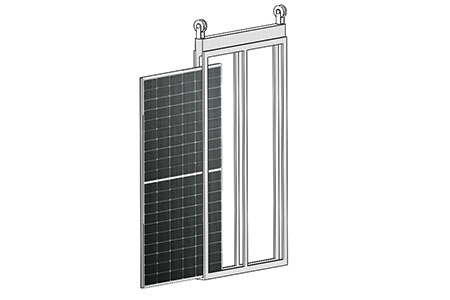

4. Full-Size PV Module Compatibility

Vertical specimen holders support large solar panels with stable exposure geometry, enabling simultaneous testing of multiple modules without irradiance shadowing.

5. Designed for IEC-Oriented Test Sequences

Optimized as a UV preconditioning stage before damp heat, thermal cycling, or combined climatic tests required in photovoltaic qualification workflows.

Technical Parameters of UV Preconditioning Test Chamber for Solar Panels

Name | UV Preconditioning Chamber |

Model | UVP-02 |

Internal Dimension (mm) | 1450*745*2500 D*W*H |

Overall Dimension (mm) | 1875*1210*2800 D*W*H |

Specimen Holder Size(mm) | 1400*2400 W*H |

Specimen Capacity | 2/4/6/... Pieces |

Irradiation Source | Fluorescent UVA lamps (20 pieces) and UVB lamps (10 pieces) |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Bandwidth | UVC: (< 0.1%) UVB: (3% to 10% of total UV) UVA: (90% to 97% of total UV) |

Irradiance Control | ●The wavelength of 280 nm - 320 nm:7.5 k Wh/m2 ●The wavelength of 320 nm - 400 nm:15 k Wh/m2 ●Maximum Irradiance in the UV range: < 250 W/m2 |

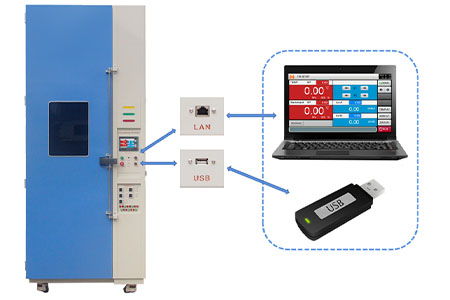

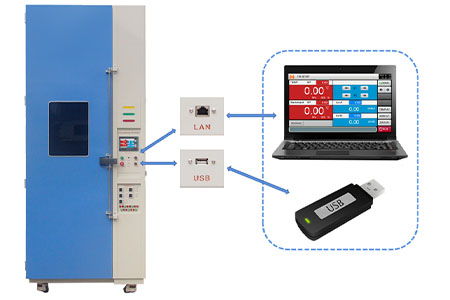

Controller | Programmable color LCD touch screen controller |

Exterior Material | Steel Plate with protective coating |

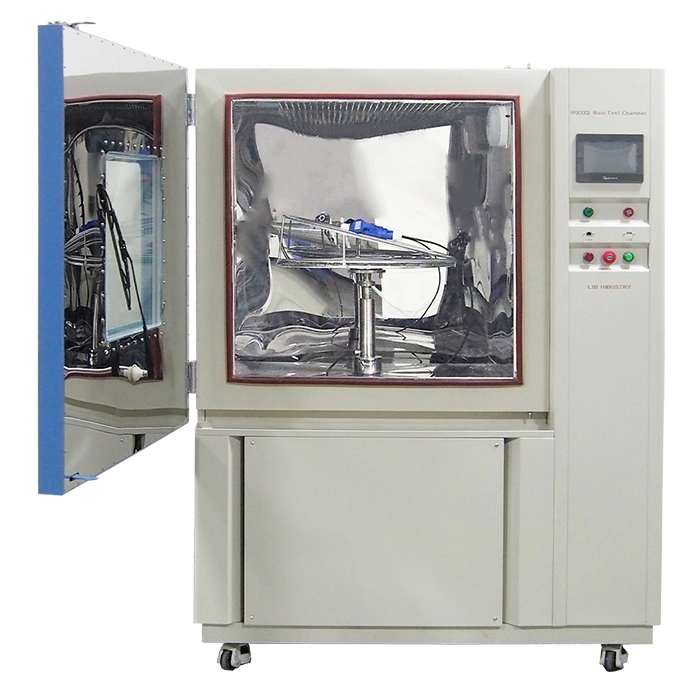

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Power Supply | AC380V 50Hz 3Phase |

Engineered Details of UV Preconditioning Test Chamber for Solar Panels

High-Density UVA / UVB Lamp Array | 20 pcs of UVA lamps and 10 pcs of UVB lamps, forming a UV spectrum dominated by 320–400 nm (UVA) with controlled 280–320 nm (UVB) contribution. The total UV irradiance is maintained below 250 W/m², ensuring uniform exposure across the specimen plane while minimizing center-to-edge deviation during extended UV preconditioning cycles.

|

|

Rigid Vertical PV Module Holder | The vertical specimen holder is for full-size photovoltaic modules, maintaining a fixed lamp-to-sample distance throughout the test. The reinforced frame supports customizable module quantities (2, 4, 6 or more panels).

|  |

SUS304 Stainless-Steel Test Workroom | SUS304 stainless steel workroom, offering excellent resistance to UV radiation, corrosion, and operating temperatures up to 90 °C. The smooth surface finish supports long-duration testing while maintaining structural integrity and cleanliness.

|  |

Programmable Touchscreen Control System | A color LCD touchscreen controller enables multi-step test programming(120 programme 99 steps, including UV energy, air temperature regulation, and automatic test sequencing. Integrated alarms and data logging ensure operational safety and test traceability.

|

|

Practical Questions - UV Preconditioning Test Chamber for Solar Panels

Q1: How is UV exposure controlled—by time or by energy?

The chamber controls UV preconditioning primarily by accumulated radiant energy (kWh/m²), which provides higher repeatability and aligns better with IEC photovoltaic test logic.

Q2: Can LIB industry customize the system for different PV module formats?

Absolutely. LIB industry customizes specimen rack dimensions, module quantity, UV configuration, and control logic to match your exact IEC test workflow.

Q3: What support does LIB industry provide beyond the chamber itself?

LIB industry delivers complete PV testing support, including chamber customization, test sequence consultation, installation guidance, operator training, and long-term technical service.

Contact LIB Industry Today

Choose a UV Preconditioning Test Chamber for Solar Panels engineered to translate IEC 61215 / IEC 61730 requirements into controllable, repeatable UV stress.

Contact LIB industry today inquiry@libtestchamber.com for an IEC-oriented configuration proposal, professional test consultation, and complete photovoltaic reliability testing solutions within 1~3 hours.

Custom Configurations | 3-Year Warranty | Lifetime Technical Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia