Electronics products are along with us with almost every aspect in our lives, from the smart phones we use every day to complex industrial control systems, electronics cover too many products and information. To ensure the performance and stability of electronics, performing environmental testing of electronics plays a crucial role.

Why we can draw this solid conclusion?Electronics are operated under different environmental conditions and may be affected by various factors such as high temperature, low temperature, humidity, vibration and etc. These factors may cause electronics’ malfunction, performance degradation or even damage. The environment test chamber is specifically designed to provide authentic environment conditions or more extreme environment elements, through the rigorous testing of electronics, we can assess their reliability and durability in the actual use condition.

An environment test chamber can reproduce a complex natural environment such as high and low temperature, high and low humidity, vibration and etc. You can test electronics in a combined or single environment. For example, you can perform high/low temperature test, thermal shock test, high/low humidity test and vibration test to access their performance and reliability under those harsh and complicated environments.

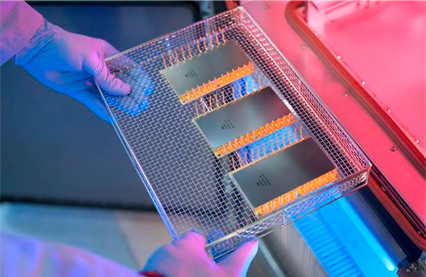

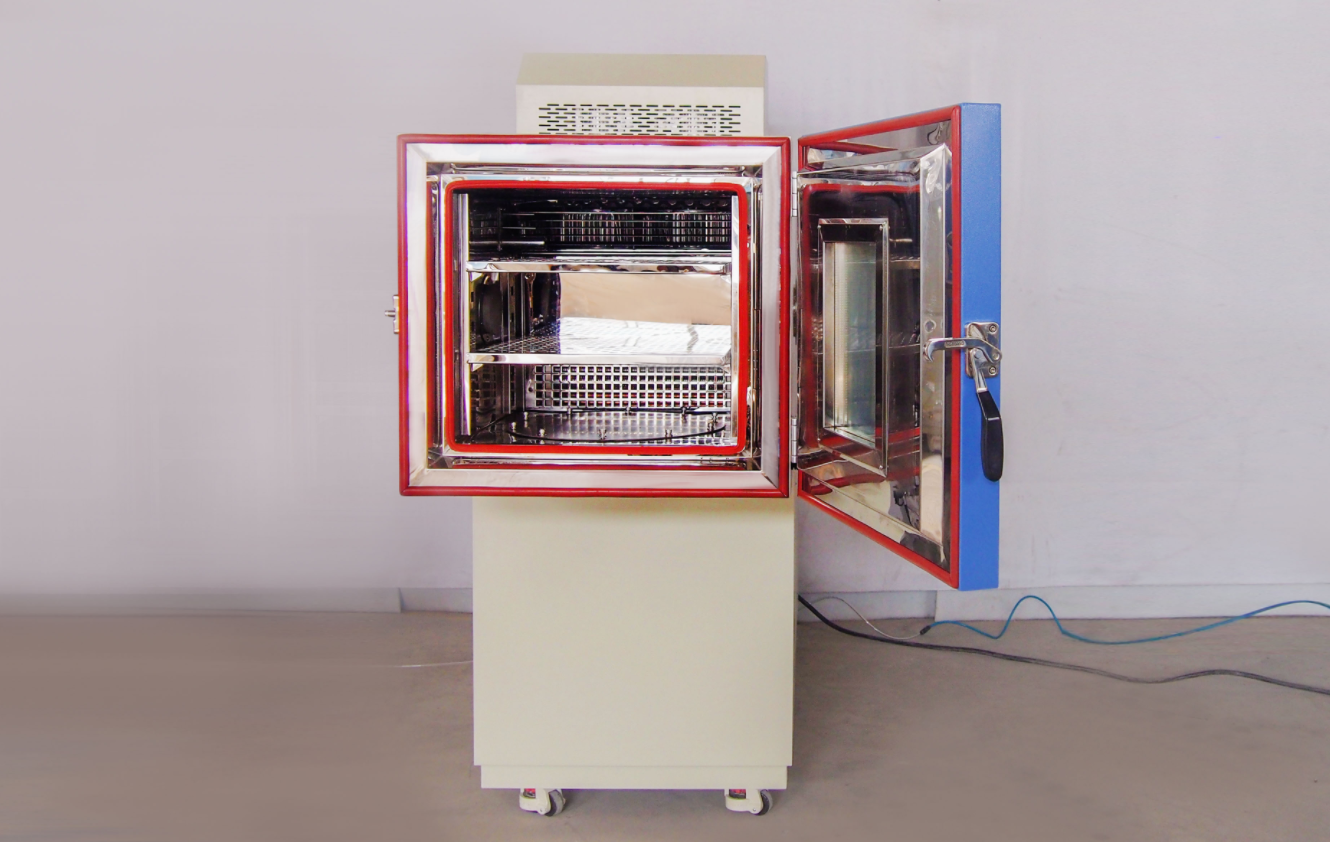

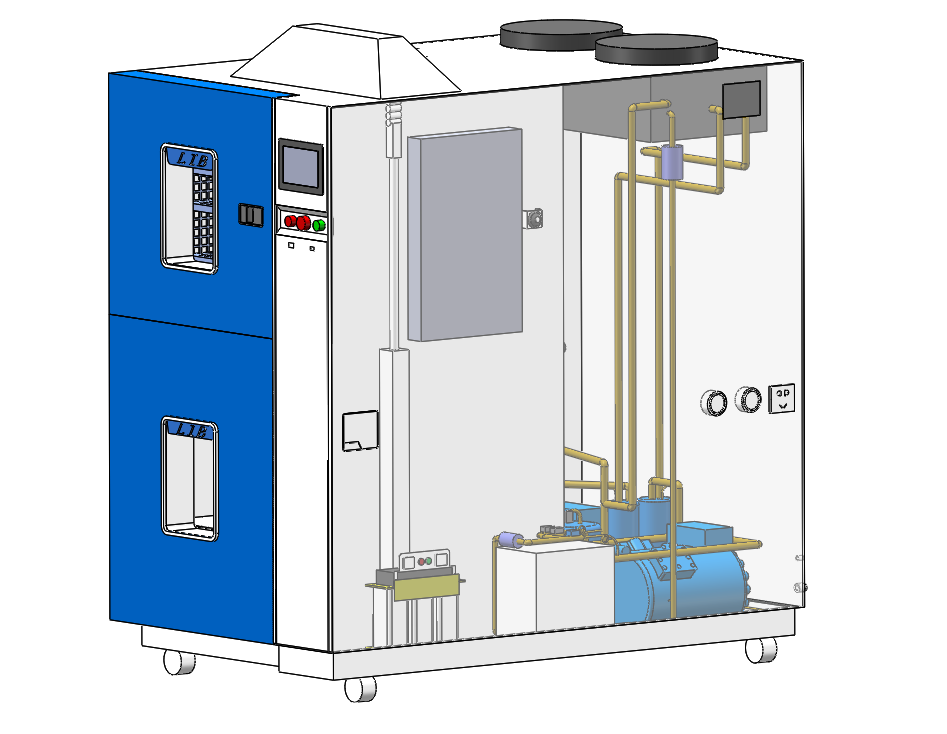

Obviously, the main structure of the environment test chamber is determined by its function. It is usually composed of a chamber body, temperature control system, humidity control system, vibration system, PID controller, etc. The chamber body is workroom where electronics to be tested. The size of chamber body depends on your specimens’ size, usually the various models can satisfy most kinds of test pieces and custom environment test chamber can meet nonconventional size products. To obtain the most real usage situation, the cable hole is equipped to facilitate power electronics.

For the temperature control system, it consists of heating system, cooling system and temperature sensor. Through the precise temperature control algorithm, the temperature control system can maintain the temperature in the workroom within the set range, and can achieve rapid temperature change. The humidity control system is composed with water tank, humidifier, humidity sensor. The humidity control system can maintain the humidity in the chamber within the set range to meet the needs of different tests. Vibration systems are used to simulate mechanical vibration. It usually includes a vibration table, power amplifier, refrigeration system (fan) and probe. The vibration system can generate vibration of different frequencies, amplitudes and directions to simulate the vibration that electronic products may encounter during actual use.

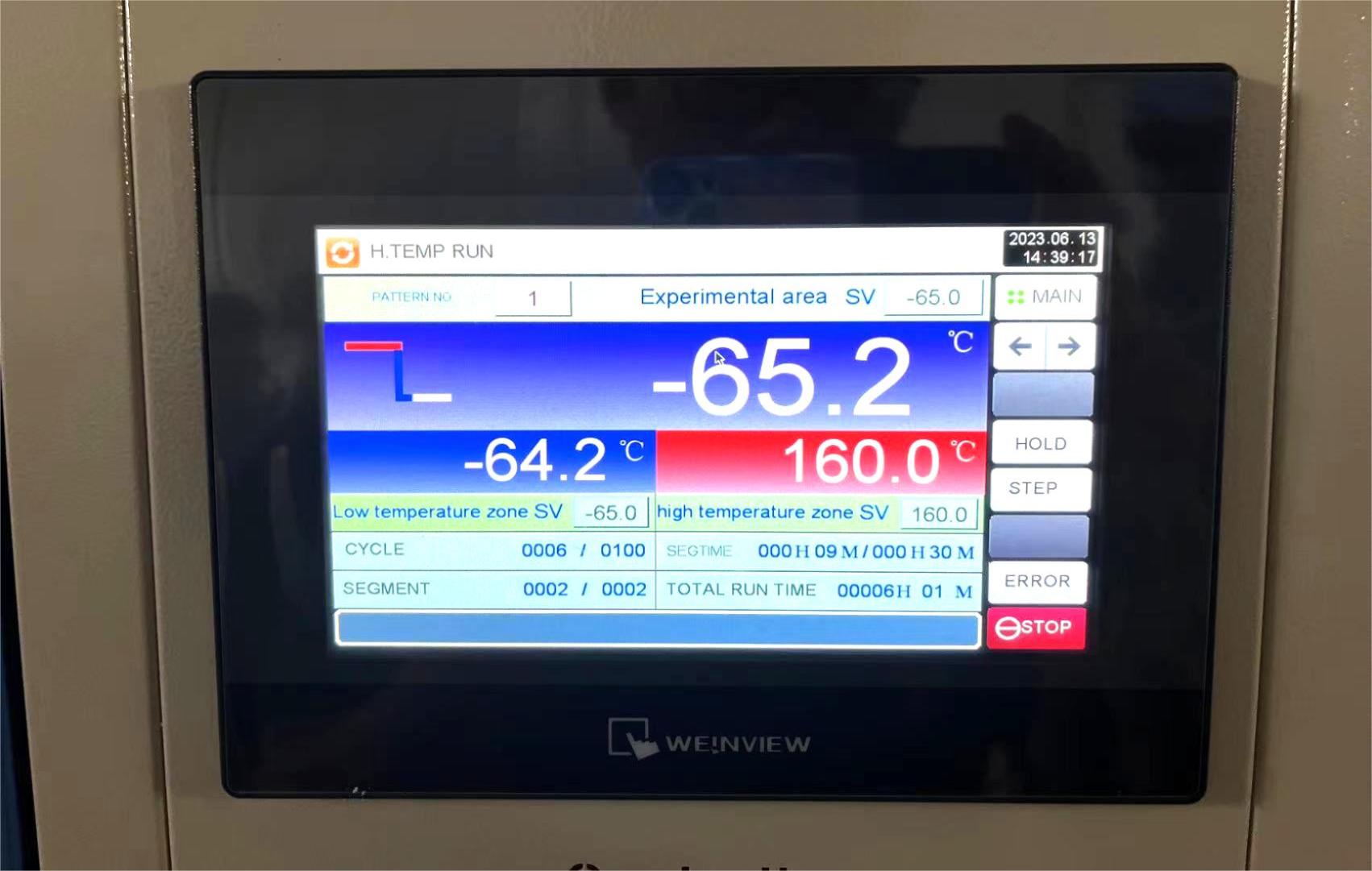

On the PID controller, you can set test time, cycles, temperature and other relevant parameters. It records various parameters in the test chamber. Through detailed data acquisition and matched computer software, we can monitor and analyze the performance changes of electronics in the test process in real time, and provide data support for evaluating their reliability. At the same time, the operator can observe the physical changes of the test parts through the observation window, you can get an overall analytics’ performance changes of the test parts by combining the data.

Environment test chamber for electronics testing is widely used in communications, automotive, aerospace, national defense and many other fields. Let's take a smart phone that we are familiar with in our daily life as an example. Suppose we want to test the environmental adaptability of the circuit board of a new smart phone.

First, place the circuit board in the test chamber. Set the temperature range of the test chamber, such as gradually increasing from -40 ° C to 80 ° C, changing the temperature at a certain rate, and maintaining it at a specific temperature at intervals of time (for example, 1 hour). In the whole process of temperature change, the performance of the circuit board are continuously monitored and record data on the controller. At the same time, the environment test chamber is also set up the corresponding humidity conditions, from low humidity (such as 30%RH) to high humidity (such as 80%RH), and in different humidity stages for a long time stay test and perform humidity cycle test.

In addition, vibration testing may also be carried out, with a vibration table installed in the test chamber to simulate vibration during transportation and further verify the reliability of the board in a comprehensive environment.

Through such detailed tests, the performance and reliability of the electronic device (circuit board) can be comprehensively evaluated under different temperature, humidity and vibration conditions, which provides an important basis for product improvement and quality assurance.

The environmental test chamber can become an indispensable equipment for testing electronic components because of the continuous innovations and improvement of the technical speciality of the environment test chamber.

For example, for the temperature, the control accuracy, sensor accuracy, deviation, fluctuation, adjustable range are all get improved. In the same way, for the humidity function, the overall aspects get more precise. And the vibration frequency and amplitude are more accurate. At the same time, the intelligent PID control level of the test chamber is also constantly improving, through the introduction of advanced sensor technology and automatic control system, remote monitoring, automatic alarm and data analysis can be achieved.

On the other hand, the application field of electronic product test chamber is constantly expanding. With the continuous emergence of new electronic products and technologies, the demand for electronic product test chambers is also increasing. Therefore, the design and function of the test chamber for electronic products also need to constantly adapt to new market demands and technological development trends.

The future of environmental test chambers

In short, the environment test chamber, as an important tool to ensure the quality and reliability of electronic products, plays an irreplaceable role in today's scientific and technological development. With the continuous progress of science and technology and the constant change of market demand, the electronic product test chamber will continue to develop and innovate, and make greater contributions to promote the development of the electronic product industry.

The above is about environmental testing of electronics some of the introduction, if you are interested, need more information and specifications, please leave your contact information and test requirements, our team will soon contact you and give professional solutions. You can also clickhttps://www.libtest.com/products/temperature-and-humidity-chamber/ to obtain the product information of different models.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia