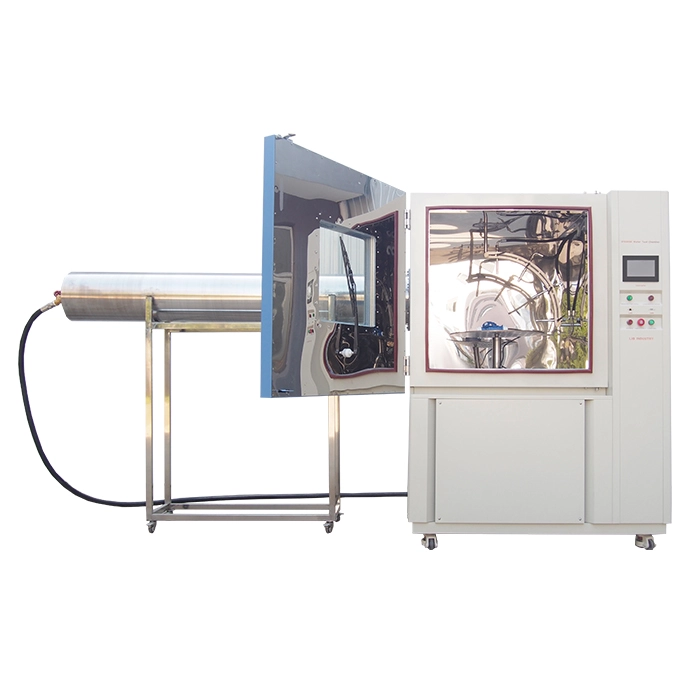

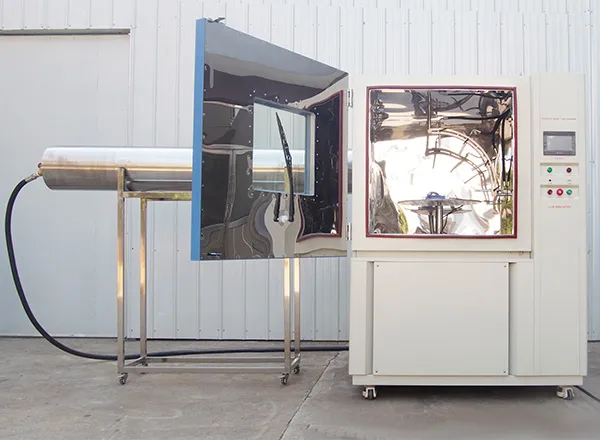

Features and Benefits of IP6K9K Test Chamber

1. Dual Protection Testing – IPX6K & IPX9K in One Unit

The IP6K9K test chamber supports both IPX6K and IPX9K waterproof tests, enabling users to perform multiple high-pressure water tests in a single unit.

2. Precise High-Pressure Spray

IPX6K: Spray pressure up to 1000 kPa (10 kg), with a water flow rate of approximately 75 ± 5 L/min.

IPX9K: Injection water pressure between 8000–10000 kPa (80–100 bar), spray flow rate of 14–16 L/min.The spray is directed at four fixed angles—0°, 30°, 60°, and 90°—with precise pressure and flow control to ensure accurate and repeatable testing.

3. Flexible and Adjustable Turntable

Adjustable height and rotation speed, allowing it to accommodate samples of various sizes and shapes, including a waterproof electrical interface for powering up.

4. Automated Water Intake System

The IP6K9K test chamber allows direct connection to the lab faucet, enabling fully automated water intake and testing. The inlet is a standard 1/2 inch (13.5 mm) diameter for easy installation.

5. Safety Monitoring and Alerts

Equipped with high and low water level alarms, the system ensures uninterrupted testing.

Specifications of IP6K9K Test Chamber

Model | RC-012 |

Interior Volume (L) | 1200 |

Testing Platform Diameters | 600mm |

Testing Platform Speed | 5±1 r.p.m |

Turntable loads | 50kgs |

Testing Platform Height | 230-350mm |

IPX6K | Internal Diameter of Nozzle | 6.3mm |

Water Flow Rate | 75L/min ±5% |

Water Pressure | approx.1 000 kPa |

Distance from Water Spraying to Specimens | between 2.5 m and 3 m. |

IPX9K | Water Spray Angle | 0°, 30°, 60°, 90° |

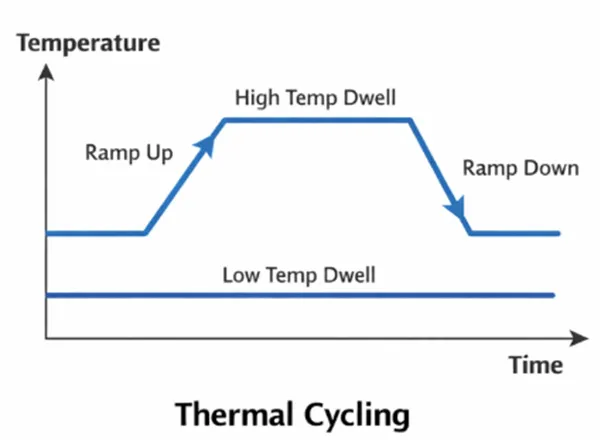

Water Spray Temperature | Ambient ~ +88℃ (Adjustable) |

Spray Nozzle | Four, 30 Seconds each position |

Distance from Water Spraying to Specimens | 10~15cm |

Water Pressure | 8000-10000 Kpa (Adjustable) |

Water Flow Rate | 14L-16L/min |

Controller | Programmable color LCD touch screen controller,Ethernet connection, PC Link |

Door Lock | Electromagnetic lock |

Water supply system | Storage water tank; Booster pump; Automatic water supply; Water purification system; |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Configuration of IP6K9K Test Chamber

Workroom | SUS304 stainless steel, resistant to high-temperature, high-pressure and moisture corrosion. High-elasticity heat-resistant silicone rubber sealing ring to prevent water vapor leakage during the testing process. The turntable equipped with a waterproof power supply simulates high-pressure water impact at different angles.

|

|

IPX6K and IPX9K nozzles | Stainless steel heat-resistant material can withstand high temperatures and pressures for a long time and is not prone to scaling or corrosion IPX6K nozzle: Linear high-pressure nozzle, inner diameter 6.3mm, powerful linear jet, stable water pressure, flow rate up to 75L /min. IPX9K nozzle: Fan-shaped high-pressure nozzle, simulating high-temperature and high-pressure impact. The spray angle is automatically switched (0°, 30°, 60°, 90°).

|

|

Intelligent touch controller | The touch screen controller enables users to set parameters such as test time, temperature, injection cycle, and automatic angle switching. Data recording and fault alarm function. Remote control via PC and export of test data.

|  |

Water Circulation System | A closed water circulation system saves water and improves testing efficiency. Including the circulating water tank, filtration system, high-pressure water pump and piping system.

|  |

Choose LIB

LIB offers full technical support and global after-sales service to ensure the long-term stable operation of your IP6K9K test chamber.LIB promises: rapid response within 24 hours, original factory parts, remote guidance, on-site maintenance, and an extended 36-month warranty.

Contact us immediately to learn more details and customized solutions for the IP6K9K test chamber!

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia