Hydrolysis aging test refers to the evaluation of how PU (polyurethane) synthetic leather degrades when exposed to prolonged high-temperature, high-humidity environments or alkaline conditions. For PU synthetic leather used in shoes, upholstery, bags, and other products, hydrolysis can cause serious deterioration: mechanical properties (tensile strength, tear resistance, elongation) may drop, surface may turn sticky , cholder, delaminate, or discolor.

Conducting hydrolysis tests helps manufacturers and quality-control labs assess the long-term durability of PU synthetic leather. By identifying how materials respond under stress, companies can:

optimize PU formulations for better hydrolytic stability,

predict service life and failure modes,

reduce warranty claims and improve product reliability.

There are three widely adopted methods for testing hydrolytic resistance of PU synthetic leather:

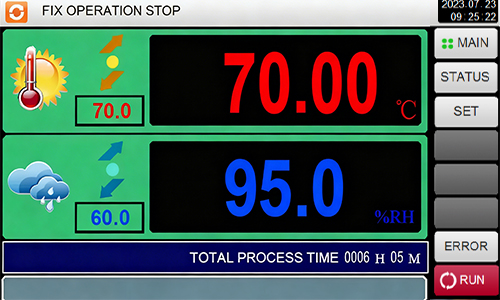

This method exposes samples to a highly humid and hot environment to simulate a “tropical” or “jungle” climate. The typical test condition is 70 °C, 95% RH, for 168 hours (7 days). After exposure, samples are hung in a standard environment (23 ± 2 °C, RH ~50%) for 2 hours, then observed for surface changes (e.g., tackiness).

Samples are immersed in a 10% NaOH aqueous solution at room temperature. The immersion durations are commonly 12 h, 24 h, 48 h, 72 h. After soaking, the samples are washed, and their surface appearance and other properties are evaluated.

Similar to method B, but the 10% NaOH solution is heated to 70 °C, and samples are immersed for 1h, 2h, 3h, or 4h. After the test, samples are rinsed, and pH of the rinsing solution is tested (for example, needs pH ~6–8).

Among these, Method A (constant temperature and humidity method) is widely regarded as the most effective in reflecting the hydrolysis resistance of synthetic leather under real humid conditions (such as tropical environments), and is therefore frequently used as the primary evaluation method.

Method A offers several advantages over other techniques in a temperature and humidity chamber :

Realistic Simulation: 70 °C and 95% RH replicate humid tropical climates,producing stress similar to long-term use.

Repeatable Results: Using a precise temperature and humidity chamber ensures stable and reproducible testing conditions.

Extended Observation: Test durations range from 168 hours (7 days) up to 2400 hours, allowing for thorough aging assessment.

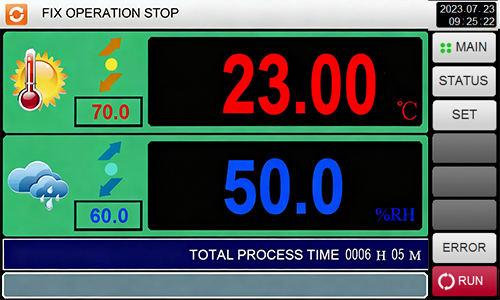

Objective Evaluation: After treatment, samples are conditioned at 23 ± 2 °C and 50% RH for 2 hours, and assessed for surface tackiness, choldering, delamination, and color change.

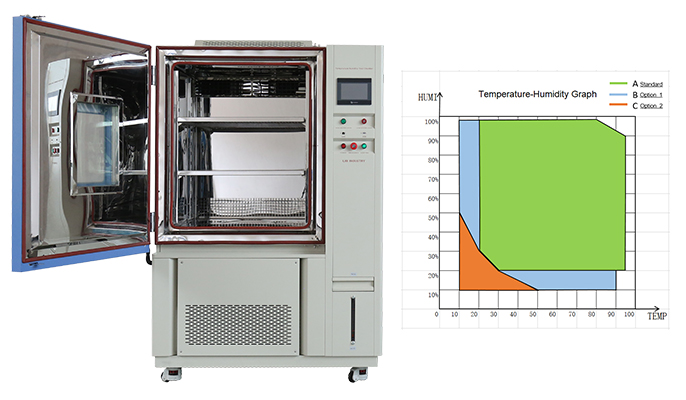

Accurate and repeatable hydrolysis evaluation requires a chamber that can maintain stable high-temperature and high-humidity conditions for hundreds to thousands of hours.

The LIB industry Temperature and Humidity Test Chambers are engineered specifically to meet these demands, making them the ideal equipment for Method A hydrolysis testing of PU synthetic leather.

Category | Specification |

Temperature Range | -70°C / -40°C / -20°C ~ +150°C |

Temperature Fluctuation | ±0.5°C |

Humidity Range | 20% ~ 95% RH |

Humidity Stability | ±2.5% RH |

Heating Rate | 3.0°C/min (higher rates customizable) |

Continuous Operation | Supports long-term tests of 500h / 1000h / 2400h |

Controller | 7-inch PLC touchscreen, up to 99 programmable cycles |

Workroom Volume | 100L / 225L / 500L / 800L / 1000L (custom sizes available) |

Shelves | Adjustable stainless-steel shelves, 50 kg load per layer |

| |

The Temperature Humidity Chamber is engineered to maintain high humidity and elevated temperatures with exceptional precision, even under continuous multi-week operation.

High-performance sensors ensure accurate climate control

PID micro-adjustment maintains micro-level stability

Uniform airflow ensures consistent conditions across all sample positions

This makes the Temperature Humidity Chamber one of the most stable long-duration environmental systems in its class.

Designed for laboratories and production environments that operate 24/7, the Temperature Humidity Chamber integrates:

Tecumseh compressors for high reliability

Eco-friendly R404A or R449A refrigerants

Corrosion-resistant SUS304 interior chamber

Reinforced humidification system with anti-scale design

These features ensure long service life, minimal downtime, and excellent performance consistency.

The advanced PLC touchscreen controller allows users to create complex environmental profiles with ease.

Key capabilities include:

Up to 99 programmable steps

Multi-segment cycling for long-term stability studies

Automatic water refill or manual water supply options

Real-time trend curves, alarm system, and remote monitoring

The interface is user-friendly and optimized for high-volume laboratory and production use.

The Temperature Humidity Chamber chambers offer multiple volume configurations to suit a variety of industries.

Adjustable shelves for flexible sample arrangement

Reinforced holders for heavy or oversized items

Customizable chamber sizes for large components

Whether testing small PU sheets or full-size shoe assemblies, the workspace design supports efficient multi-sample loading.

Unlike standard environmental chambers, the Temperature Humidity Chamber is optimized specifically to withstand high humidity (90–95% RH) for exceptionally long periods.

High-efficiency evaporator coils

Humidity circulation protection

Anti-condensation structure design

Stable water supply and vaporization system

This ensures smooth and consistent operation throughout extended usage cycles.

Step 1 – Sample Preparation: Cut PU samples to standard sizes or place full shoes on perforated shelves. Ensure samples do not touch each other or chamber walls.

Step 2 – TH Test Chamber Setup: Set the temperature and humidity chamber to 70 °C, 95% RH. Wait until conditions stabilize before starting the timer.

Step 3 – Hydrolysis Exposure: Maintain samples under these conditions for 168 hours, or longer as needed (up to 2400 hours).

Step 4 – Conditioning: After exposure, transfer samples to 23 ± 2 °C and 50% RH for 2 hours.

Step 5 – Evaluation: Observe surface for tackiness, cholders, delamination, or color change. Measure tensile strength, elongation, tear resistance, and compare with pre-test values.

The temperature humidity environmental chambers ensure all conditions are tightly controlled, providing consistent and objective results that cannot be achieved with simple immersion or boiling tests.

Ensure your PU synthetic leather products meet the highest hydrolysis resistance standards. LIB industry’s Temperature Humidity Chamber provide precise, reliable, and long-term testing capabilities.

Contact LIB industry today inquiry@libtestchamber.com to equip your lab with the Temperature Humidity Chamber, backed by a 3-year warranty, lifetime support, rapid 1–3 hour service response, and 7–15 working day delivery. Protect your brand and ensure product durability with the most reliable hydrolysis testing solution.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia