Proven RTU Aging Case by LIB Industry

Modern electronic devices are no longer tested under idle or no-load conditions.

Products such as RTUs (Remote Terminal Units) operate continuously in the field, generating significant internal heat while being exposed to changing environmental temperatures. This combination of electrical load + thermal stress places far greater demands on a temperature test chamber than traditional environmental testing.

In high-load applications, the real challenge is not simply reaching the target temperature—it is maintaining temperature stability, ramp rates, and uniformity while the products themselves are generating heat.

LIB industry specializes in temperature test chamber solutions ranging from standard models to deeply customized systems, enabling customers to validate product reliability under real operating conditions rather than laboratory assumptions.

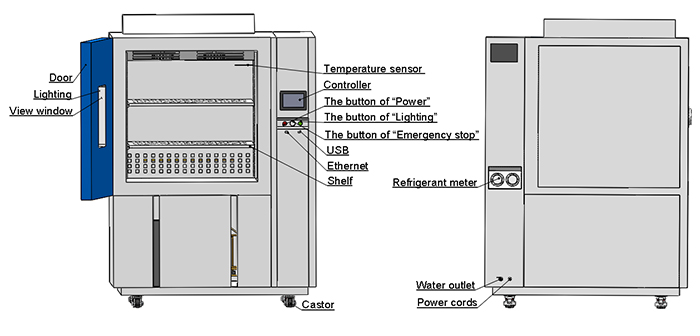

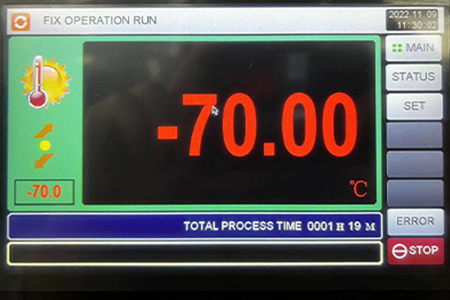

In August 2022, a customer approached LIB industry seeking a temperature test chamber for RTU high–low temperature cycling and aging tests.

The application involved:

100 RTUs operating simultaneously

Individual power: 10 W per unit

Total thermal load: 1000 W

Temperature cycling range: 0°C to 70°C

Required cooling rate: 1°C/min (average)

Continuous powered operation throughout the test

Unlike conventional environmental tests, this project required the chamber to perform reliably under full electrical and thermal load, not just under empty or lightly loaded conditions.

Maintaining a 1°C/min cooling rate while dissipating heat from 100 active RTUs is a significant engineering challenge. Any insufficient cooling margin, airflow imbalance, or control instability would compromise test repeatability and long-term reliability.

This requirement became the defining factor of the entire system design.

To ensure stable performance over years of operation, LIB industry went beyond the customer’s baseline requirements and introduced several value-added design measures.

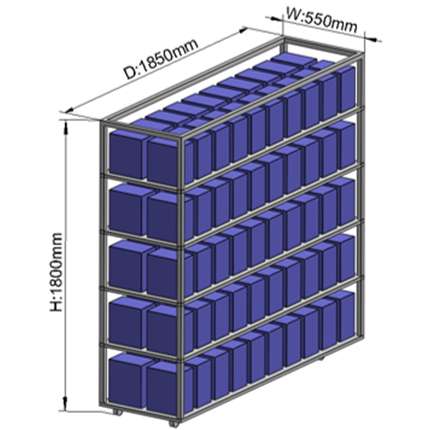

The combined weight of the RTUs and aging carts was estimated at approximately 800 kg.

To ensure safe and efficient operation, the temperature test chamber was equipped with a ramp pedal design, allowing carts to be smoothly rolled in and out of the chamber without damaging the floor or structure.

This design significantly improves daily testing efficiency while reducing long-term mechanical stress.

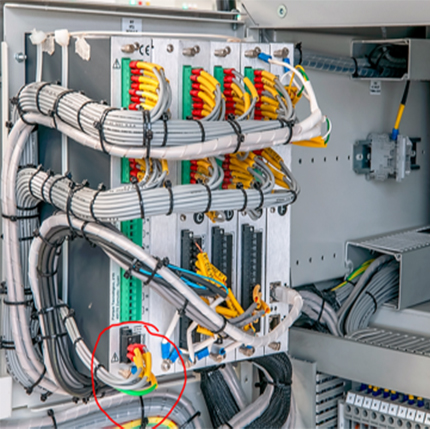

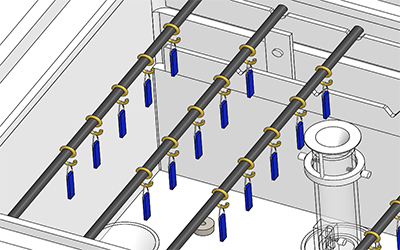

Rather than relying on external power routing, the system integrates:

A built-in, controller-managed power supply

Two customized aging carts supplied by LIB industry

ESD-type casters with braking function

Electrical interfaces using Phoenix 3-terminal connectors (P/N: 1757022)

This integrated design ensures safe powered testing, clean cable management, and consistent electrical connections throughout long-duration aging cycles.

|

|

|

|

Although the actual product heat load was 1000W, LIB industry deliberately designed the cooling system based on a 2000W thermal load.

This performance redundancy ensures:

Stable 1°C/min cooling under worst-case conditions

Reduced compressor stress during long-term operation

Higher system reliability over extended service life

By designing beyond nominal requirements, the temperature test chamber remains stable not only on day one, but throughout years of continuous testing.

| Feature | Standard Model | Customized for RTU | Advantage |

|---|---|---|---|

| Heat Load Capacity | 1000 W (typical design) | 2000 W | Easily handles 1000 W real-time heat generation from operating RTUs |

| Cooling Rate | 1.0 °C/min (no load) | 1.0 °C/min (full load) | Maintains fast and stable cooling even under high thermal load |

| Maximum Loading Weight | 50 kg per sample shelf | 800 kg | Reinforced base supports two heavy-duty aging carts |

| Power Integration | Not integrated (external wiring required) | Built-in 24V DC, controller-managed | Direct power control via chamber controller for safe aging tests |

| Interface System | 50 mm / 100 mm cable ports | 200 × Phoenix 1757022 terminals | RTU-specific design enables fast, secure, and organized connections |

| Floor Design | Flat chamber floor | Ramp pedal design | Smooth and safe access for 800 kg aging carts |

The RTU project was not built as a one-off solution.

It was developed on the same engineering foundation used across LIB industry’s standard temperature test chamber product lines.

|

|

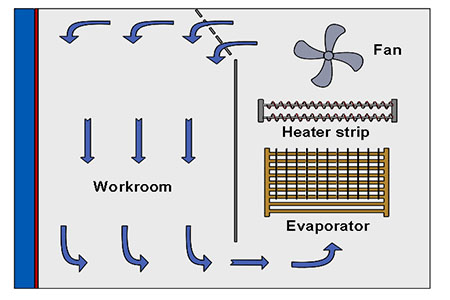

Optimized air circulation systems using centrifugal fans

Top air supply and bottom return for vertical forced convection

Uniform temperature distribution with deviation within ±2.0°C

High-precision PID control for stable ramp rates under load

Reliable cooling systems capable of sustained operation

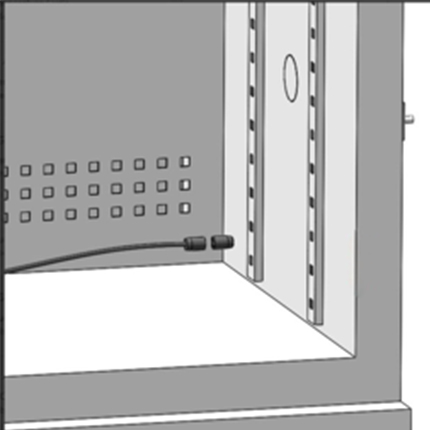

Support for powered testing through sealed cable holes

Model | T-100 T-225 T-500 T-800 T-1000 | |||

Interior Volume | 100L 225L 500L 800L 1000L | |||

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | |||

Temperature Fluctuation | ± 0.5 ℃ | |||

Temperature Deviation | ± 2.0 ℃ | |||

Cooling Rate | 1 ℃ / min | |||

Heating Rate | 3 ℃ / min | |||

Cooling system | Mechanical compression refrigeration system,Environmentally Friendly Refrigerant ,French TECUMSEH compressor | |||

Controller | Programmable color LCD touch screen controller, Ethernet connection | |||

| ||||

|  |

| ||

These core technologies are present not only in customized systems, but also in LIB industry’s standard chambers.

TH Series (Temperature & Humidity Chambers)

Designed for daily reliability testing, aging tests, and environmental verification.

Rapid Temperature Change Chambers

Suitable for ESS (Environmental Stress Screening) and accelerated reliability testing.

Walk-in Temperature Test Chambers

Ideal for large components, complete assemblies, or batch testing scenarios.

Each series inherits the same focus on load-aware design, airflow uniformity, and long-term stability demonstrated in the RTU case.

Temperature fluctuation controlled within ±0.5°C

Maximum temperature deviation within ±2.0°C

High-accuracy PT100 Class A sensors ensure consistent results

SUS304 stainless steel interior for corrosion resistance

Industrial-grade steel exterior structure

Comprehensive safety systems including over-temperature protection, grounding, and electrical monitoring

ESD design concepts applied where powered testing is required

In this RTU project:

Order placed: February 2023

System delivered: March 2023

This rapid delivery reflects LIB industry’s mature production system and global project experience.

The RTU case demonstrates one key principle:

reliable testing starts with designing the chamber around the application—not the other way around.

If you are testing products that generate heat during operation and require stable, repeatable temperature cycling, contact LIB industry inquiry@libtestchamber.com for a free technical evaluation.

3-year warranty covering the complete system for long-term reliability

Lifelong technical support from experienced application and service engineers

Fast remote technical response within 1–3 hours to minimize test interruptions

Global spare parts availability, ensuring quick replacement and sustained operation

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia