When testing conditions push beyond conventional limits, extreme low temperature is no longer just a parameter—it becomes a critical risk factor. At temperatures as low as –120°C, even minor instability can lead to irreversible sample damage, inaccurate data, or serious safety concerns.

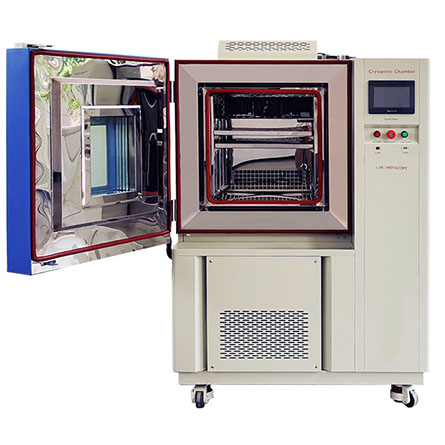

For industries operating at the edge of material performance, reliability at cryogenic temperatures is not optional. LIB industry high-precision cryogenic chambers are engineered specifically to deliver stable, safe, and repeatable performance where ordinary low-temperature equipment fails.

|  |

Reaching –120°C is not simply a matter of increasing refrigeration capacity. At cryogenic levels, the entire testing system faces a different set of challenges:

Temperature instability becomes amplified, where even small fluctuations can invalidate test results

Material brittleness and thermal stress increase sharply, demanding highly uniform temperature control

Frost formation and sealing failure threaten both equipment integrity and sample safety

Operational risks rise, requiring advanced protection for both the system and the operator

Many standard environmental test systems are designed for –40°C or –70°C and only extended to operate at lower temperatures. In contrast, LIB industry cryogenic chambers are purpose-built from the ground up for long-term, safe operation at ultra-low temperatures.

LIB industry cryogenic chambers provide stable and continuous operation down to –120°C, without forced derating or compromised performance. The refrigeration architecture is optimized specifically for deep-cold environments, ensuring reliable temperature pull-down and long-duration test stability.

At cryogenic temperatures, control accuracy defines test credibility. LIB industry integrates:

Multi-point temperature sensing throughout the workspace

Advanced PID control algorithms tuned for deep-cold dynamics

Consistent temperature uniformity and stability, even below –100°C

This ensures repeatable results for critical qualification, validation, and research testing.

Extreme cold introduces severe thermal contraction and energy loss challenges. LIB industry cryogenic chambers feature:

Reinforced chamber structures designed to withstand thermal stress

Multi-layer high-performance insulation to minimize cold leakage

Specialized sealing systems engineered specifically for ultra-low temperatures

Every structural detail is optimized to maintain long-term reliability under repeated cryogenic cycling.

Safety is the foundation of cryogenic testing. LIB industry integrates comprehensive protection mechanisms, including:

Over-temperature and over-pressure safeguards

Refrigeration system safety interlocks

Intelligent emergency shutdown logic

Operator-focused safety design throughout the test cycle

These features ensure stable operation while protecting both test samples and personnel.

–120°C cryogenic testing is essential in high-reliability industries and is commonly conducted with reference to recognized international standards.

Aerospace and space components – Extreme low-temperature exposure for qualification and reliability validation, referenced to MIL-STD-810 and aerospace thermal testing practices.

Power batteries and energy storage systems – Low-temperature performance and safety evaluation aligned with IEC 62660, UN 38.3, and automotive validation requirements.

Electronics and semiconductors – Reliability screening and brittle failure analysis based on IEC 60068-2 low-temperature test methods and JEDEC guidelines.

Advanced materials and composites – Cryogenic durability and thermal stress testing referenced to ASTM and ISO environmental testing practices.

Cryogenic chambers represent a long-term testing investment. LIB industry ensures worry-free operation through comprehensive global support:

3-year warranty covering complete system reliability

Lifelong technical support from experienced engineers

1–3 hour rapid remote response to minimize test interruptions

Global spare parts availability for fast recovery and sustained operation

This commitment ensures stable performance throughout long-term and high-value testing programs.

When testing moves into the cryogenic range, precision and safety are no longer optional—they are essential.

Contact LIB industry today inquiry@libtestchamber.com to discuss your –120°C testing requirements and receive a customized cryogenic chamber solution designed for extreme performance and absolute safety.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia