Whether you are running NSS, AASS, or CASS tests, the credibility of your results depends on one critical factor: uniform salt fog distribution with stable chemistry over time.

Yet in real laboratories, many failed or rejected tests are not caused by incorrect standards, but by maintenance-related design limitations of the salt spray chamber itself.

|  | |||

Model | S-150 | S-250 | S-750 | S-010 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

Temperature Range | Ambient ~ +60 ℃ | |||

Humidity Range | 95% ~ 98% RH | |||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||

Spray Type | Continuous / Periodic | |||

Salt Fog Collected | Fog collector and fog measure cylinder | |||

Air Preheating | Saturated air barrel | |||

Spraying System | Atomizer tower and Spray nozzles | |||

Controller | PID controller | |||

Material | Glass fiber reinforced plastics | |||

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||

This article explores how proper maintenance ensures reliable salt spray testing — and more importantly, how LIB industry designs Salt Spray Chambers to make accuracy easier, not harder, to achieve.

The atomizing system is the heart of any salt spray chamber.

If the spray nozzle becomes partially blocked or damaged, fog distribution immediately suffers — leading to uneven deposition, unstable collection rates, and invalid test data.

In many conventional salt spray chambers:

Plastic or low-grade nozzles develop salt crystallization

Narrow internal surfaces trap deposits

Nozzle cleaning requires tools, increasing the risk of damage

As a result, technicians delay maintenance — and accuracy silently degrades.

LIB industry Salt Spray Chambers use high-precision Quartz Nozzles, selected for:

Exceptional corrosion resistance

Ultra-smooth internal surfaces

Long-term dimensional stability

|

|

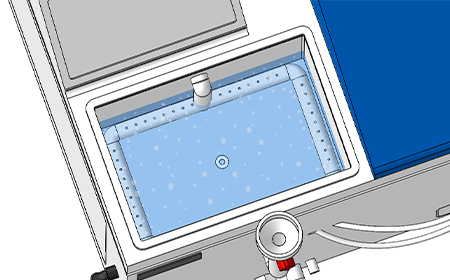

| Corrosion-Resisitant Workroom | Modular grooves are used for holding samples |

salt spray tower |

cylinder |

spray collector |

Maintenance Best Practice

Never clean a spray nozzle with metal wires or needles. This scratches the internal surface and permanently alters the spray pattern. Instead:

Dismantle the nozzle

Soak it in warm distilled water or a mild acidic solution

Rinse thoroughly before reinstallation

LIB industry chambers feature an easy-to-disassemble spray tower, allowing routine cleaning to be completed in minutes — not hours.

Result:

Consistent fog distribution with a stable sedimentation rate of

1–2 ml / 80 cm² · h, fully compliant with ASTM B117 and ISO 9227.

LIB industry doesn’t rely on “more frequent maintenance” —we engineer chambers that are easy enough to maintain that technicians actually do it.

International standards such as ASTM B117 and ISO 9227 specify a 5% sodium chloride solution, but achieving true compliance requires more than following a ratio.

Always use NaCl with ≥99.5% purity.

Impurities commonly found in industrial or table salt — such as iodine, copper ions, or anti-caking agents — can:

Artificially accelerate corrosion

Suppress corrosion reactions

Cause inconsistent results between test cycles

One of the most common reasons third-party corrosion data is questioned or rejected is non-compliant salt chemistry.

Use distilled or deionized water only.

Tap water introduces minerals that alter conductivity and pH, undermining repeatability.

To meet standard requirements:

Dissolve 5 ± 1 parts by weight of NaCl

In 95 parts by weight of purified water

LIB industry chambers are designed to maintain solution stability once prepared — reducing operator-dependent variability.

Maintaining correct pH is one of the most overlooked challenges in salt spray testing.

As brine sits in the tank, it absorbs carbon dioxide from the air, gradually lowering pH.

Many chambers rely on:

Manual pH correction

Frequent sampling

Operator experience

This approach becomes unreliable, especially during long-duration NSS tests.

LIB industry Salt Spray Chambers incorporate a specialized bubble device within the brine pipeline.

How It Works

Aerates the salt solution before atomization

Pre-heats air in the saturated air barrel

Reduces CO₂ absorption and chemical drift

|  |

The Result

For Neutral Salt Spray (NSS) testing, the collected fog maintains a stable pH between 6.5 and 7.2 — from the first hour to extended test durations.With LIB industry, pH stability shifts from operator experience to system design.

To ensure continuous compliance with global standards, LIB industry recommends the following routine checks:

| Component | Action | Purpose |

|---|---|---|

| Saturated Air Barrel | Verify water level and temperature | Ensures fully humidified air and prevents fog drying |

| Fog Collector | Measure hourly deposition | Confirms uniform fog across the test volume |

| Water Seal | Inspect airtightness | Prevents salt fog leakage into the laboratory |

| Brine Tank | Check for sediment | Keeps filters and bubble device clean for stable pH |

Design Matters

Every item on this checklist can be verified on a LIB industry Salt Spray Chamber without special tools or extended downtime — a critical advantage for high-throughput laboratories.

Q1: How often should I clean the quartz nozzles?

A: For optimal performance, inspect the nozzles weekly. Thanks to LIB industry’s easy-to-disassemble spray tower, cleaning takes only a few minutes without specialized tools. Regular cleaning ensures uniform fog distribution and consistent sedimentation rates.

Q2: Can I use regular table salt for my tests?

A: No. Only high-purity NaCl (≥99.5%) ensures accurate and repeatable results. Impurities in table salt can alter corrosion rates and may lead to failed or invalid tests. LIB chambers are designed to maintain stable chemistry when correct consumables are used.

Q3: How does LIB ensure pH stability during long NSS tests?

A: LIB industry chambers are equipped with a bubble device that aerates the brine and pre-heats the saturated air. This keeps the pH stable between 6.5–7.2, minimizing operator intervention and ensuring reliable test results over extended periods.

Q4: What chamber size should I choose for my lab?

A: LIB offers a range from compact S-150 to high-capacity S-020 chambers. Selection depends on your sample size, throughput, and testing standards. Our technical team can help match a chamber to your exact needs.

Q5: How can I reduce maintenance downtime while ensuring test accuracy?

A: With robust GRP construction, easy-to-clean quartz nozzles, and integrated pH stabilization, LIB chambers are engineered to minimize routine maintenance while maximizing data reliability, letting your lab focus on analysis instead of upkeep.

From the compact S-150 to the high-capacity S-020, LIB industry provides corrosion testing solutions engineered for accuracy, durability, and ease of operation.

Contact LIB industry today inquiry@libtestchamber.com for a quotation or technical consultation — and ensure your salt spray testing is built on results you can trust.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia