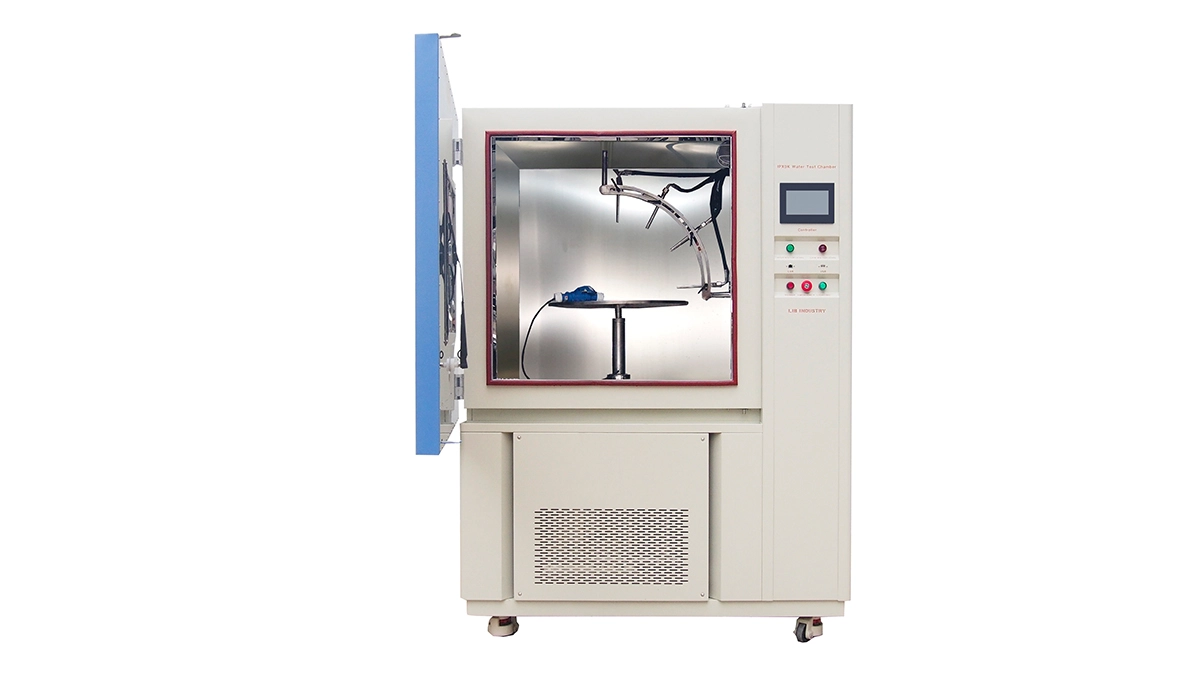

Environmental testing chambers (TH Series) provide critical simulation capabilities for research, development, and quality assurance across industries. These systems offer precise control over temperature and humidity conditions, enabling professionals to evaluate product reliability and performance under various environmental stresses. Understanding their operation, calibration, and maintenance is essential for achieving consistent, accurate results.

This article provides you with a common FAQ about LIB humidity and temperature control chambers https://www.libtest.com/products/temperature-humidity-environmental-control-chamber.html , helping you better understand these test chambers.

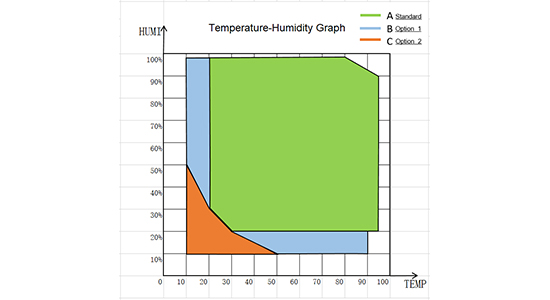

The compressor starts operating at 85℃ instead of being activated at a higher temperature.

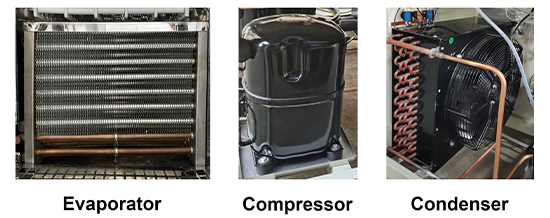

as a protective measure. This design prevents refrigerant overheating, which would trigger automatic safety shutdowns. The cooling cycle operates through a coordinated process:

Evaporation: Liquid refrigerant absorbs heat and transitions to low-pressure vapor within the evaporator.

Compression: The compressor draws in this vapor, compresses it into a high-pressure, high-temperature gas.

Condensation: The hot gas moves to the condenser, releasing heat to the surrounding medium and condensing back into a high-pressure liquid.

Expansion: The liquid passes through an expansion valve (capillary tube), reducing its pressure before returning to the evaporator to repeat the cycle.

The standard model of LIB humidity and temperature control chambers has a minimum temperature of -120℃. Customization for lower temperatures is also available. In addition to mechanical refrigeration, LIB also offers water-cooled temperature and humidity control chambers.

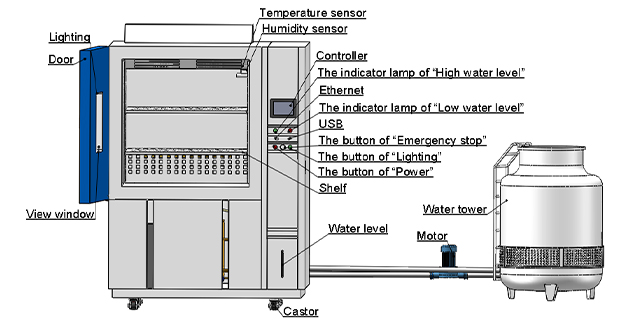

These chambers reliably perform extended tests (e.g., dual 85°C/85% RH) due to two integrated systems:

Automatic Water Supply: Ensures a consistent and timely water source for maintaining high humidity levels.

Advanced PID Control: Intelligently allocates power between the refrigeration and humidification systems for optimal stability and efficiency.

Precision is paramount. LIB calibration protocol ensures data integrity for both temperature and humidity readings.

Table: Calibration Overview

Parameter | Method | Standard Used | Goal |

Temperature | 9-Point Test, 6 Probes | DT-100 Probe | Controller display matches the average chamber temperature |

Humidity | Psychrometric Comparison | Reference Hygrometer | Controller reading matches the standard reference table value |

Heating is achieved via dedicated heating wires installed in a layer behind the workroom workspace. Power capacity is scaled to the chamber's volume:

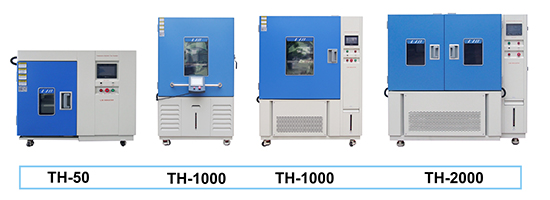

Table: Heating Element Specifications by Model

Chamber Model | Heating Wire Power |

TH-50 / TH-80 / TH-100 | 1500 W |

TH-225 / TH-500 / TH-800 | 2000 W |

TH-1000 / TH-1500 | 3200 W |

Standard Connections: Water inlet/outlet valves feature an 11.5mm diameter and include 2 meters of drainage hose.

Test Ports: Located a standard distance from the insulation. A minimum spacing of 10cm is required between multiple ports.

Ramp Rates: A rapid change rate of 10°C per minute is standard within a typical operating range (e.g., -60°C to +85°C).

Custom Windows/Ports: Adding optical glass viewports or custom ports typically extends production time by 5-10 business days.

Refrigerant: Permanently sealed within the copper compressor loop with no routine depletion. Leak risk is minimal and primarily associated with weld integrity during transit, mitigated by specialized packaging.

Silicone Seals: Designed for longevity with a recommended replacement interval of 3 years to ensure ongoing integrity.

Guidance: We provide comprehensive video installation support to complement written manuals, ensuring correct setup.

Conclusion: Modern Humidity and Temperature Control Chambers are complex instruments integrating robust mechanical systems with precise digital control. Understanding their operation, calibration needs, and specifications is key to leveraging their full potential for effective environmental simulation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia