When outdoor lighting products—including LED street lamps, tunnel luminaires, floodlights, and solar-powered units—are exposed to heavy rain, wind-driven water, or airborne dust, even minor sealing failures can lead to corrosion, short circuits, or complete system failure. For engineers and quality managers, the key question is not whether products will encounter such conditions—but whether they have been tested rigorously and reliably before deployment.

Ingress Protection (IP) testing is therefore critical. LIB industry offers two specialized machines to cover the full spectrum of IP65 protection: the IPX5 Water Jet Tester and the IP6X Dust Chamber, both designed to meet IEC 60529 standards and provide repeatable, reliable, and efficient testing for outdoor lighting applications.

IP65 consists of two parts:

“6” – Full dust ingress protection (IP6X)

“5” – Resistance to water jets from any direction (IPX5)

IEC 60529 defines the test procedures for both dust and water protection. To achieve genuine IP65 compliance, both aspects must be verified independently, simulating real-world conditions for outdoor luminaires.

Dust and water affect enclosures differently:

Dust particles can penetrate micro-gaps, requiring controlled airflow and dust concentration to verify integrity.

Water jets exert dynamic pressure on seals and housings, testing resistance to rainfall or splashing water.

By performing separate IPX5 and IP6X tests, manufacturers obtain accurate, repeatable results, ensuring long-term reliability and compliance.

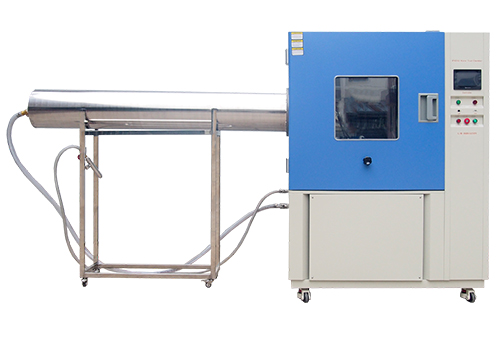

The IPX5 Water Jet Tester simulates rainfall and water jets from all directions on outdoor lighting products.

|  |

Key Parameters:

Nozzle diameter: 6.3 mm

Water flow rate: 12.5 L/min

Water pressure: 30–100 kPa

Distance from lamp: 3 m

Rotating test table for full-surface exposure

IEC 60529 IPX5 compliant

Testing ensures:

Verification of seal integrity

Resistance to heavy rain and splashing water

Reliable performance under real outdoor conditions

Adjustable water pressure and nozzle angles for different product sizes

Programmable rotation speed and test duration

Corrosion-resistant stainless steel structure

PLC/touchscreen control with automatic cycles and data logging

Custom fixtures supporting lamps up to 200 kg

LED street lamps, tunnel luminaires, and floodlights

Early detection of enclosure weaknesses reduces field failures

Supports R&D validation and mass production quality control

Improves product reliability and brand competitiveness

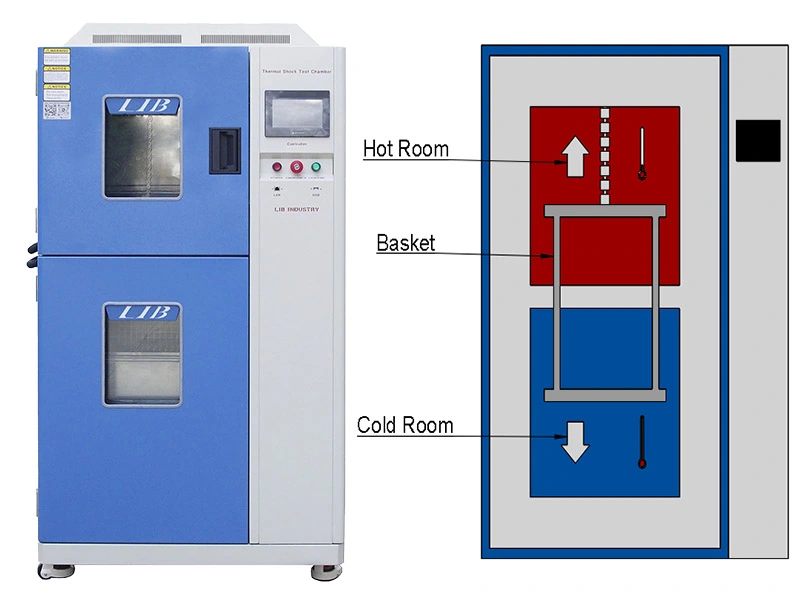

The IP6X Dust Chamber evaluates luminaires for complete dust protection, simulating dusty environments.

|  |

Key Parameters:

Test dust: ISO 12103-1 A2 fine dust

Particle size: ≤ 50 μm

Dust concentration: 2–4 kg/m³

Test duration: 2–8 hours

Negative pressure applied to verify enclosure integrity

IEC 60529 IP6X compliant

Fully enclosed chamber with uniform dust distribution

Adjustable dust concentration, airflow, and duration

Transparent observation window for monitoring

Supports lamps up to 200 kg, including irregular shapes

Heating tube prevents dust agglomeration

PID-controlled airflow ensures stable, repeatable results

LED street lamps and highway tunnel luminaires in dusty environments

Solar-powered outdoor lighting units

Detects weak points in enclosures early

Ensures reliable, repeatable, and standard-compliant results

Improves product durability and market competitiveness

Dust uniformly distributed in sealed chamber

Negative pressure applied to detect any ingress

PID-controlled airflow ensures repeatability

Rotatable and height-adjustable racks

Load capacity up to 200 kg

Proper alignment guarantees uniform exposure

Lamps rotated under controlled water jets

Adjustable pressure and nozzle angles

Automatic cycle control for reproducibility

Real-time observation and data logging

Safety valves and corrosion-resistant components

Transparent windows and secure lid operation

Although IPX5 and IP6X tests are performed separately, together they provide full IP65 verification, confirming that outdoor luminaires can withstand both heavy rainfall and dust storms.

LIB industry provides customized fixtures, automated testing, and turnkey solutions, supporting R&D, mass production, and certification compliance.

Why Choose LIB:

3-Year Warranty & Lifetime Technical Guidance – Ensures worry-free operation.

Replacement Units – Provided at no additional cost if malfunctions cannot be resolved remotely.

24/7 Global Support – Experienced English-speaking team ready to assist worldwide.

Critical Spare Parts Availability – Stocked in international centers for fast delivery within 7–15 days.

Detailed Instructions Provided – Guarantees safe shipping, installation, and operation of your testing equipment.

Benefit: Ensure your outdoor lighting products achieve reliable, long-term IP65 performance with full support from LIB industry.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia