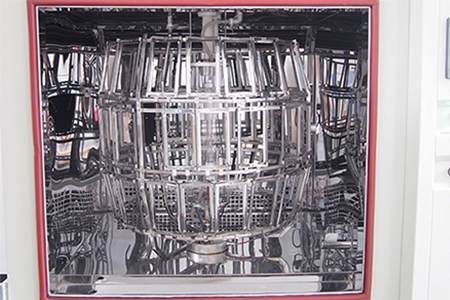

As a global manufacturer of environmental simulation chambers with over 16 years of expertise, LIB industry’s radiant exposure xenon test cabinet accurately reproduces real-world outdoor conditions, including full-spectrum sunlight, temperatures, humidity, and water condensation. Designed for rigorous material testing, this cabinet ensures reliable simulation for plastics, coatings, automotive components, and other outdoor-exposed products.

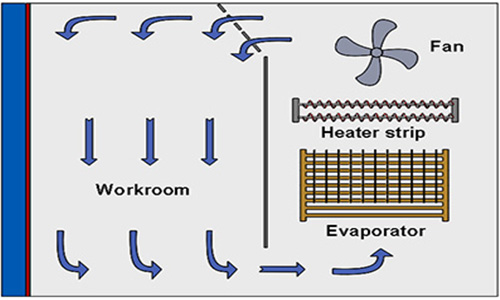

The cabinet features a xenon arc lamp providing uniform high-intensity illumination.Temperature control ranges from Ambient to 100 ℃, while relative humidity is maintained between 50% and 95% RH. The water spray system simulates natural dew formation and rainfall, enabling accelerated weathering tests.

LIB industry’s xenon test cabinet ensures consistent, repeatable results for quality assurance, R&D, and compliance with weathering standards such as ISO 4892-2 and ASTM G155.

Standard Models: XL-S-500,XL-S-750

Applicable Standards: IEC 60068-2-5, IEC 60068-2-27,ASTM G26,ISO 105, ISO 4892-2, ASTM G155, ASTM G151, ASTM G155,ISO 105-B02 (EN) (DIN), ISO 105-B04 (EN) (DIN).

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia