Electronics, lithium batteries, LED lighting, and photovoltaic panels are often exposed to extreme heat and humidity, which can lead to failures such as battery bulge, circuit short circuits, or LED degradation. Without proper testing, these failures can occur unexpectedly, resulting in costly recalls or reduced product lifespan.

The Double 85 Test addresses this by simulating extreme wet and thermal environments in a controlled setting using a PV Environmental Test Chamber, allowing manufacturers to identify weaknesses early and enhance product reliability.

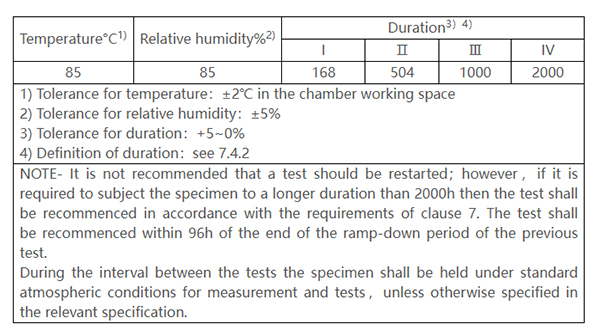

The Double 85 Test is an accelerated aging method where products are continuously exposed to 85°C ±2°C temperature and 85% RH ±3% humidity. The purpose of this test is to evaluate:

Weather resistance

Sealing performance

Electrical stability

High temperature accelerates chemical reactions inside materials, while high humidity promotes moisture ingress, corrosion, and insulation degradation. By maintaining these conditions for extended periods, manufacturers can simulate years of real-world exposure in just hundreds or thousands of hours.

This test is a core requirement in international standards such as IEC 60068, IEC 61215, and JESD22-A101, and is widely used in photovoltaic components, automotive electronics, lithium batteries, and LED lighting.

For common consumer electronics such as smartphones and smart watches, industry standards typically require at least 500 hours of Double 85 Testing to prevent failures in hot and humid regions, such as screen malfunctions, battery swelling, or internal circuit shorts. For high-reliability products like outdoor power equipment or electric vehicle components, testing may extend beyond 1,000 hours to ensure long-term performance and safety.

Test Duration | Typical Applications | Notes |

168h | Small electronic devices | Basic verification |

504h | Smartphones, smart watches | Industry standard minimum |

1000h | Automotive electronics, photovoltaic panels | High reliability required |

2000h | Outdoor power equipment | Extreme reliability testing |

IEC 60068-2-67-2019 | ||

Different durations allow manufacturers to tailor testing to the specific reliability requirements of their products. Shorter tests can detect early failures in consumer electronics, while longer tests help preventing long-term failures and warranty issues.

The LIB industry Damp Heat Chamber plays a key role in Double 85 Testing by providing a controlled, stable environment to accurately simulate extreme conditions. Unlike traditional product listings, the focus here is on how the chamber helps users achieve testing goals efficiently:

· Simulate Real-World Conditions Accurately: Advanced temperature and humidity control ensures repeatable and reliable results, giving confidence in accelerated aging outcomes.

· Flexible Testing for Various Products: From small electronic devices to full-size photovoltaic panels, the chamber supports multiple test stations simultaneously, maximizing efficiency.

· Ease of Monitoring: The large observation window with internal LED lighting and intuitive programmable controller allows operators to monitor samples without interrupting tests.

· Safety and Reliability: Multiple protection systems safeguard both operators and products, enabling long-term, uninterrupted testing.

This approach ensures that manufacturers can accelerate product development, reduce warranty risks, and deliver reliable electronics and photovoltaic solutions.

LIB industry’s solutions provide manufacturers with the confidence that their products will perform reliably under extreme environmental conditions.

16+ years of experience in designing environmental test chambers

Advanced temperature and humidity control ensures precise and repeatable testing

Flexible customization: small to large chambers, single or multi-station setups

Fast pre-sales and after-sales support: 1–3 hour response time

Compliance with international standards: IEC, JESD, and others

Tailored Double 85 Test solutions for your products

Rapid quotes and consultation

Multi-volume chamber options to suit small devices or large photovoltaic panels

Reliable testing that ensures electronics and photovoltaic modules meet international standards and excel in extreme environments

Ensure your products pass the test for reliability and durability with LIB Industry’s Damp Heat and PV Test Chambers at inquiry@libtestchamber.com.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia