The aerospace industry has entered a new stage of rapid technological development. With the successful launch of manned spacecraft and the continuous advancement of satellites, avionics, and launch systems, aerospace products are becoming more sophisticated, compact, and performance-intensive. At the same time, expectations for reliability, service life, safety, and environmental adaptability have reached unprecedented levels.

Aerospace components and systems must withstand extreme temperature variations, humidity exposure, corrosion, vibration, and even vacuum environments throughout their lifecycle—from ground storage and transportation to launch, flight, and orbital operation.

As a result, environmental reliability testing is not optional; it is a fundamental requirement for aerospace qualification and mission success.

Environmental test chambers for the aerospace industry are designed to reproduce these harsh conditions under controlled and repeatable laboratory environments. LIB industry provides a comprehensive range of environmental test chambers engineered specifically to support aerospace reliability testing, fully aligned with international standards.

Environmental testing in the aerospace sector is governed by a well-established framework of international standards. These standards define test methods, severity levels, acceptance criteria, and data repeatability requirements, ensuring consistency and global recognition of test results.

Key standards applied in aerospace environmental testing include:

MIL-STD-810

A primary reference for aerospace and defense applications, covering temperature, humidity, corrosion, waterproofness, vibration, shock, and low-pressure environments.

IEC 60068 Series

International standards for environmental testing of electronic and electromechanical components, widely used for temperature, damp heat, and combined environmental tests.

ASTM Standards

Particularly ASTM B117 and ASTM G85, focusing on salt spray and cyclic corrosion testing of materials and protective coatings.

RTCA DO-160

Environmental conditions and test procedures for airborne electronic equipment, including vibration and rain testing.

IEC 60529 (IP Code)

Classification of degrees of protection against dust and water ingress.

LIB industry designs environmental test chambers with these standards as the engineering baseline, ensuring that all test systems align with aerospace qualification requirements and customer-specific specifications.

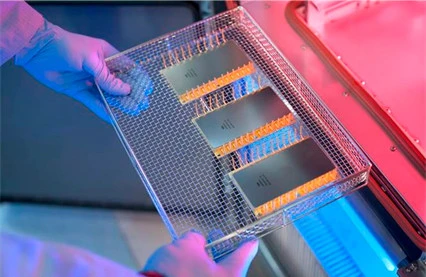

Temperature testing verifies the ability of aerospace components and assemblies to operate reliably under high-temperature, low-temperature, and rapidly changing thermal conditions encountered during ground operation, flight, and storage.

MIL-STD-810 Method 501.5 – High Temperature

MIL-STD-810 Method 502.5 – Low Temperature

IEC 60068-2-1, IEC 60068-2-2

IEC 60068-2-14, IEC 60068-2-30, IEC 60068-2-38

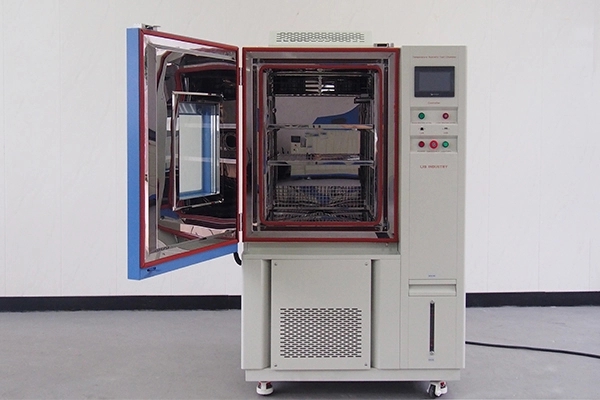

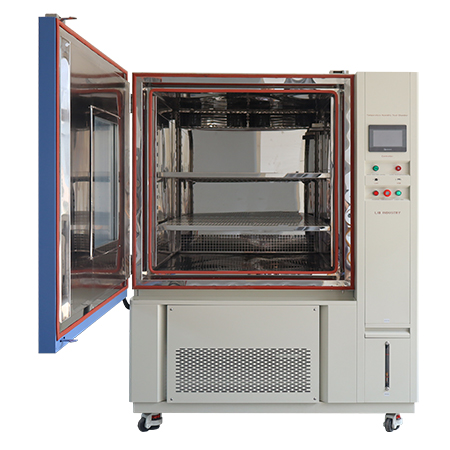

LIB industry Temperature Test Chambers | |

| Temperature and humidity chambers High-low temperature test chambers

|

These environmental chambers provide precise temperature control, uniform airflow distribution, and programmable test profiles, supporting both component-level screening and system-level qualification.

Humidity and damp heat testing evaluates resistance to moisture absorption, condensation, insulation degradation, corrosion initiation, and functional instability, which are critical risks for aerospace electronics and avionics systems.

MIL-STD-810 Method 507.5 – Humidity

IEC 60068-2-30 – Damp Heat, Cyclic

IEC 60068-2-38 – Combined Temperature/Humidity

LIB Industry Humidity Test Solutions | |

| Temperature Humidity Environmental Control Chamber Benchtop and portable humidity test chambers

|

LIB industry humidity chambers deliver stable long-duration performance with accurate sensor feedback, enabling reliable qualification and endurance testing.

Aerospace products are frequently exposed to salt-laden air, industrial pollutants, and corrosive atmospheres, particularly during coastal deployment, ground handling, and long-term storage.

MIL-STD-810 Method 509.3 – Salt Fog

ASTM B117 – Neutral Salt Spray

ASTM G85 Annex A1–A4 – Cyclic Corrosion (Salt + SO₂, Acetic Acid)

LIB Industry Corrosion Test Chambers | |

| Cyclic corrosion test chambers |

These systems allow aerospace manufacturers to evaluate the durability of coatings, fasteners, connectors, and electronic enclosures under realistic corrosive conditions.

Waterproof and ingress protection testing verifies the sealing integrity of aerospace equipment exposed to rain, spray, condensation, and immersion, especially for external enclosures and airborne electronics.

RTCA DO-160 Section 11 – Rain and Water Spray

MIL-STD-810 Method 506 – Rain

MIL-STD-810 Method 504.1 – Fluid Contamination

IEC 60529 – IPX3 to IPX9K

LIB Industry Waterproof Test Chambers | |

| IPX3 / IPX4 spray test chambers IPX5 / IPX6 / IPX6K jetting chambers |

LIB industry provides complete IP test equipment solutions for aerospace-grade enclosure verification.

Thermal vacuum testing is essential for simulating the combined effects of high vacuum and extreme temperature conditions encountered in space environments. It is a critical qualification step for satellites, sensors, and spaceborne electronic assemblies.

MIL-STD-810 Method 500.6 – Low Pressure (reference)

ECSS-E-ST-10-03 – Space Engineering Testing

ECSS-Q-ST-20 / ECSS-Q-ST-70 – Materials, Outgassing, and Cleanliness

NASA project-level thermal vacuum specifications

LIB Industry Thermal Vacuum Solutions | |

| Standard thermal vacuum chambers Customized thermal vacuum chambers

|

These systems integrate vacuum pumping, thermal control, and long-term stability, supporting component-level and subsystem-level testing for space applications.

Each system is engineered based on test object size, thermal load, vacuum level, and mission profile.

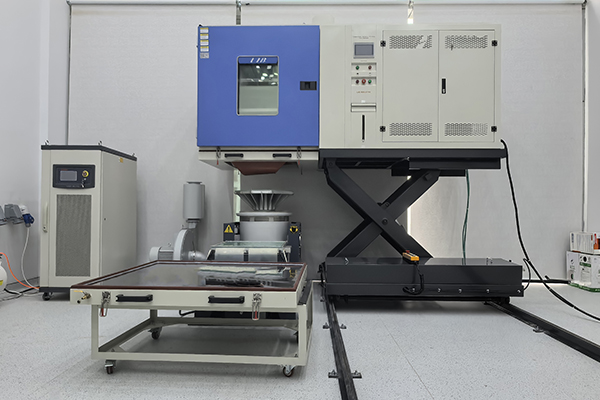

Vibration testing evaluates the mechanical integrity of aerospace products under launch loads, transportation vibration, and operational stresses. In modern aerospace qualification, vibration is often combined with temperature and humidity stresses to more accurately replicate real-world service conditions.

MIL-STD-810 Method 514.8 – Vibration

IEC 60068-2-6 – Sinusoidal Vibration

IEC 60068-2-64 – Random Vibration

IEC 60068-2-27 – Shock

RTCA DO-160 Section 7 – Vibration

LIB Industry Vibration Test Chambers | |

| |

These solutions support single-axis and multi-axis vibration, synchronized environmental control, and powered-on testing.

LIB industry develops environmental test chambers strictly in accordance with MIL, IEC, ASTM, RTCA, and ECSS standards, ensuring global acceptance of test results.

From temperature, humidity, corrosion, and waterproof testing to vibration and thermal vacuum simulation, LIB industry provides a single-source solution for aerospace environmental testing.

LIB industry supports non-standard chamber dimensions, combined stress testing, application-specific airflow design, and customer-defined qualification requirements.

High-precision sensors, optimized airflow structures, and robust control systems ensure repeatable results during long-duration aerospace tests.

From test planning and system configuration to installation, calibration, and long-term technical support, LIB industry supports aerospace customers throughout the entire equipment lifecycle.

Environmental testing is not merely a qualification step—it is a foundation for aerospace mission success. By delivering standards-compliant, engineering-focused, and fully integrated environmental test chamber solutions, LIB industry supports aerospace manufacturers from early development to final qualification, ensuring reliability under the most demanding conditions.

Discuss your aerospace environmental testing requirements with LIB industry inquiry@libtestchamber.com and build a qualification strategy aligned with mission-critical standards.

Custom Configurations | 3-Year Warranty | Lifetime Technical Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia