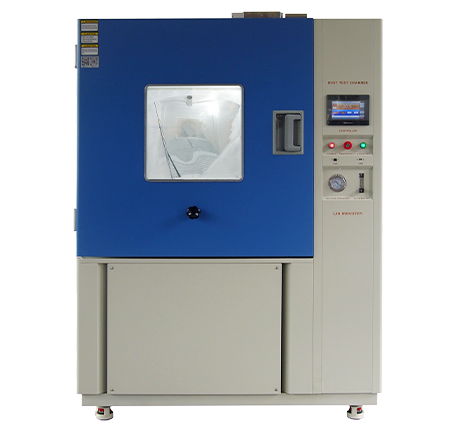

Dust can silently damage electronics, machinery, and critical devices—but how do you ensure your products are truly protected? The IP5X test chamber delivers precise, standardized dustproof testing to guarantee reliable performance under even the harshest industrial conditions.

The IP5X rating guarantees that devices are protected against solid particles larger than 1mm without compromising functionality. It is part of the international Ingress Protection (IP) standard, widely recognized in electronics, automotive, aerospace, and industrial machinery sectors.

|  |

Parameter | Specification |

Particle type | Dry talc |

Wire diameter | 50 μm |

Screen size | 75 μm |

Dust concentration | 2 kg/m³ |

Even if a tiny amount of dust enters the product, the dustproof performance ensures operational reliability. Testing simulates real-world dust exposure, delivering accurate, actionable insights.

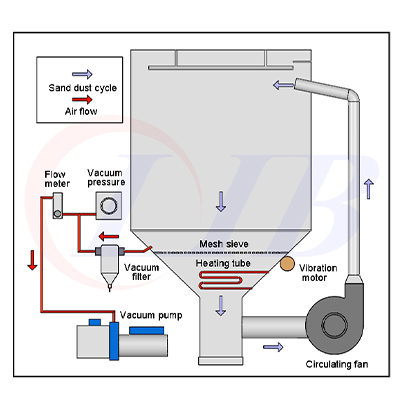

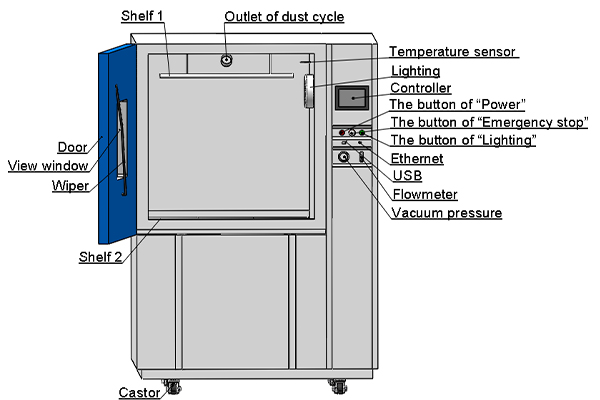

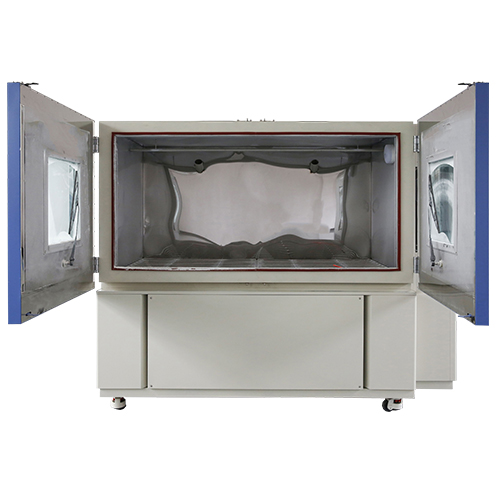

The IP5X test chamber is designed for precision dustproof testing using a controlled environment:

· Uniform dust injection: Specialized devices disperse dust evenly across the chamber.

· Optimized airflow circulation: Air ducts and filtration systems maintain stable dust concentration for repeatable testing.

· Product placement strategy: Devices are positioned to reflect actual operational conditions, ensuring realistic results.

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ | |||

Humidity Range | < 30% RH | |||

Normal Wire Diameter | 50um | |||

Nominal Width of a Gap Between wires | 75um | |||

Fight Time | 0 ~ 99H59M | |||

Blowing Time | 0 ~ 99H59M | |||

Specimen Power Outlet | Dust-proof socket 16A | |||

Controller | Programmable color LCD touch screen controller, Ethernet connection | |||

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) | |||

|  | |||

This combination of controlled dust exposure and uniform airflow guarantees that the dustproof performance evaluation is reliable and reproducible.

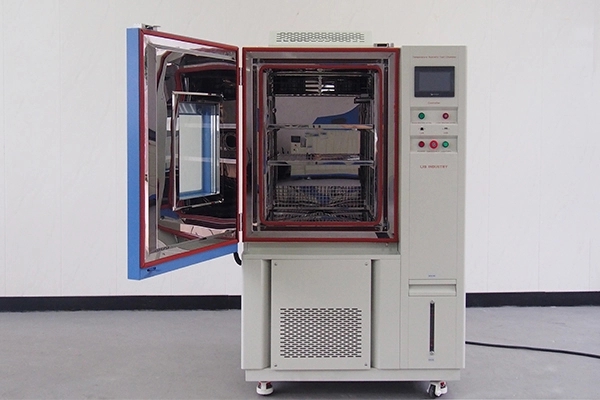

Accurate dustproof testing relies on advanced sealing:

· Door and window seals: High-quality rubber or silicone prevents dust leakage.

· Chamber connections: Gaskets and sealants maintain airtight integrity.

· Negative pressure technology: Some IP dust test chambers use slight negative pressure to block external contamination, enhancing test accuracy.

This ensures the chamber’s internal environment remains consistent, supporting precise dustproof testing.

Several elements can affect test outcomes, and LIB industry’s IP5X solutions address them effectively:

1. Consistent dust properties: Only standard-spec dust is used, screened and mixed to ensure uniform particle size.

2. Stable airflow: Advanced fans and optimized duct design maintain consistent dust distribution.

3. Correct product positioning: Proper installation prevents local obstruction or interference, providing reproducible results.

By controlling these factors, the IP5X test chamber delivers trustworthy data for evaluating dustproof performance and ensuring product reliability.

Q1: What particle size and dust concentration does the chamber support?

A: The chamber handles talc dust between 50–75 μm, with a controlled concentration of 2 kg/m³, fully circulating via a closed-loop system to ensure uniform exposure across all samples.

Q2: How is the air flow and dust distribution maintained?

A: Advanced air duct design and negative pressure sealing guarantee smooth, uniform airflow of 1–2 m/s, preventing hotspots and uneven deposition.

Q3: Is the system compatible with remote monitoring and data recording?

A: Absolutely. The touchscreen control provides real-time monitoring, with automatic data logging and USB/CSV export for compliance and traceability.

Q4: Can the dust test chamber be customized for larger or special-shaped products?

A: Yes, the chamber can be built up to 1,000 L or custom dimensions, with optional integration for vibration, temperature control, and special fixtures to accommodate irregular or oversized components.

· High-precision dust injection and circulation for consistent test results

· Advanced sealing and optional negative pressure for accurate dustproof performance measurement

· Customizable chamber sizes to suit diverse product dimensions

· Stable airflow and repeatable testing for industrial reliability

· Comprehensive after-sales support: rapid response, fast delivery, and technical consultation

LIB Industry IP Dust Testing Solution | |

| |

Upgrade your testing capabilities with LIB industry’s IP5X test chamber. Ensure your products achieve maximum dustproof performance and maintain industrial reliability under extreme conditions.

✅ Contact us today inquiry@libtestchamber.com for a tailored solution, fast delivery, and professional technical support.

✅ Free consultation to determine the optimal dustproof testing strategy for your products.

✅ 3-year warranty and lifetime service guarantee for long-term peace of mind.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia