As products increasingly move toward outdoor, industrial, and automotive applications, Ingress Protection (IP) testing has become essential for modern laboratories. Among all protection levels, IP65 is one of the most commonly requested and strictly audited ratings.

IP65 is not a single test—it represents two extreme environments: dust-tight verification and high-flow water spray resistance.

This is where the LIB Industry IP65 Tester Solution provides unmatched value for laboratory expansion.

IP65 has become a baseline expectation across industries like:

Automotive electronics and sensors

Outdoor lighting and security systems

Energy storage enclosures

Industrial control cabinets

Challenges in expansion often include:

Only dust or water testing available

Equipment from different vendors with inconsistent workflows

Complex infrastructure and compliance audits

IP65 testing exposes these weaknesses immediately.

IP6X – Dust-Tight ProtectionEnsures no dust ingress under strict test conditions. Dust concentration: 2 kg/m³ talcum powder Particle size: 75–100 μm Test duration: 8 hours Pressure simulation: optional negative pressure inside enclosure Guarantees enclosure integrity under extreme dusty conditions. | IP5X – General Dust ProtectionDust type: standard talcum powder Test duration: 2 hours Validates protection against ordinary dust environments. |

|  |

Together, IP5X and IP6X dust tests define enclosure performance across both general and extreme dust environments, forming the solid-particle protection foundation of the IP65 rating.

IPX5 – Moderate Water Jet ResistanceWater flow rate: 12.5 L/min Pressure: 30–50 kPa Test duration: ~3–5 minutes per side Simulates rain or light industrial wash-down exposure. | IPX6 – High-Pressure Water Jet ResistanceWater flow rate: 100 L/min Pressure: 100–150 kPa Test duration: 3 minutes per side Validates structural sealing under forceful water impact. |

|  |

LIB Industry provides a modular IP65 testing solution built around two dedicated systems—one for dust ingress and one for water jet testing.

Together, they form a complete IP65 verification setup, expandable to cover IPX1–X9K water and IP5X–IP6X dust testing within a single laboratory layout.

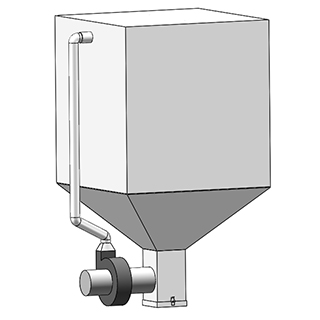

Verifying enclosure integrity in dusty environments

This system is designed to evaluate enclosure performance under controlled dust exposure, simulating both routine outdoor dust and extreme dust-tight conditions.

Typical testing scenarios include:

Automotive electronic modules

Outdoor lighting and communication enclosures

Industrial control cabinets

How the system works:

Dust is circulated evenly within the dust ingress chamber while test parameters are precisely controlled. Optional negative pressure can be applied to the test item to replicate real-world pressure differentials, ensuring reliable and repeatable results.

|  |  |

Sand-Dust Circulation System | Vacuum Connector | PLC Controller |

What laboratories gain:

Stable verification of IP5X and IP6X requirements

Repeatable test conditions aligned with IEC 60529 and ISO 20653

Flexible chamber configurations for different sample sizes

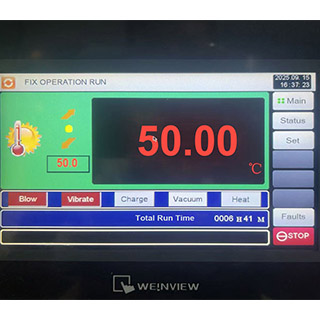

Key technical capabilities (summary)

| Item | Specification |

|---|---|

| Supported IP ratings | IP5X, IP6X |

| Test dust | Standard talcum powder |

| Temperature range | Ambient to +50 °C |

| Pressure simulation | Optional negative pressure |

| Standards | IEC 60529, ISO 20653 |

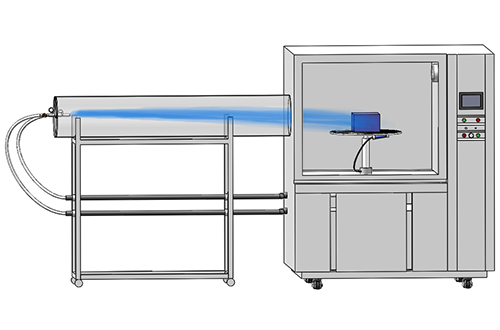

Validating enclosure sealing under water jet impact

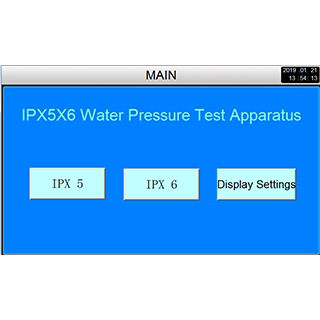

The water spray test chamber evaluates sealing performance under moderate to high-pressure water jets, simulating rain exposure, wash-down, and industrial cleaning conditions.

Typical testing scenarios include:

Outdoor electrical equipment

Automotive components

Energy storage enclosures

How the system works:

Multi-directional nozzles deliver controlled water flow while the rotating turntable ensures uniform exposure on all sides of the test item. Water pressure and flow are automatically regulated to maintain standard-compliant test conditions.

|  |  |

| Nozzle with Flow Meter | Turntable with Waterproof Power Supply | Smart Controller |

What laboratories gain:

Reliable IPX5 and IPX6 verification

Consistent, repeatable spray coverage

Efficient handling of large or heavy samples

Key technical capabilities (summary)

| Item | Specification |

|---|---|

| Supported IP ratings | IPX5, IPX6 |

| Water flow / pressure | 12.5–100 L/min, 30–150 kPa |

| Spray system | Multi-directional nozzles |

| Sample handling | Rotating turntable |

| Standards | IEC 60529, ISO 20653 |

Yes. LIB industry supplies high-grade talcum powder with stable particle size and performance, validated for long-term use and fully compliant with IEC 60529 requirements for IP5X and IP6X dust tests.

Pipe and side connections are sealed using flexible sealing materials wrapped around the interfaces before tightening.

For frequent connections, quick connectors can be used to ensure both airtightness and operational convenience.

Noise is well controlled and typically below 65 dBA.

Short vibration periods (around 10 seconds) may occur to prevent dust adhesion. Low-noise fans further reduce overall operating sound.

Yes. As IPX5 (~30 kPa) and IPX6 (~100 kPa) involve high water pressure, the turntable is equipped with straps or fixing tools to keep specimens stable during testing.

The water spray test chamber uses a closed-loop water circulation system, maintaining stable flow and pressure.

One full tank supports long-duration continuous testing without frequent refilling.

Yes. In accordance with IEC 60529, nozzles are mechanically fixed to the rack using dedicated mounting holes and screws, preventing movement under high-pressure water and ensuring accurate spray direction.

Expertise in IEC 60529 & ISO 20653 compliance

Integrated IP testing setups covering IPX1–X9K and IP5X–IP6X

Tailored solutions for lab layout and sample types

Global technical support and spare parts

3-year comprehensive warranty covering core systems

Lifetime technical support provided by senior engineers

Rapid remote diagnostics and response within 1–3 hours

From IP5X–IP6X dust to IPX5–IPX6 water, LIB Industry delivers tailored, integrated IP testing solutions. Contact us inquiry@libtestchamber.com to design your system today.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia