Corrosion testing plays a pivotal role in ensuring product durability across industries—from automotive to electronics. LIB’s Salt Spray Cabinet stands out by offering Neutral Salt Spray (NSS), Acetic Acid Salt Spray (AASS), and Copper-Accelerated Acetic Acid Salt Spray (CASS) within a single unit. Designed to meet major global testing standards, this cabinet delivers accuracy and efficiency for rigorous quality control and R&D.

AASS (Acetic Acid Salt Spray): Adds glacial acetic acid to NSS, reducing pH to around 3.1–3.3—commonly used for decorative coatings and anodic aluminum.

CASS (Copper-Accelerated Acetic Acid Salt Spray): Further enhances AASS with copper chloride, intensifying corrosion for demanding tests like aerospace and high-end finishes.

ISO 9227 formalizes all three methods as standard salt spray tests for evaluating metallic material corrosion resistance.

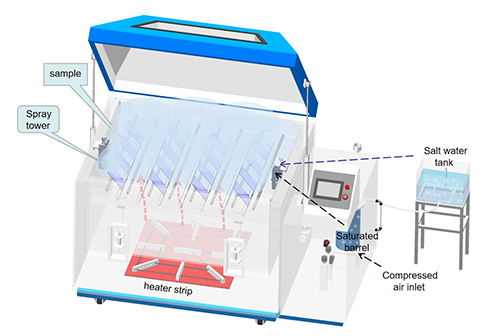

Supports NSS, AASS, and CASS in a single chamber—no need for separate devices.

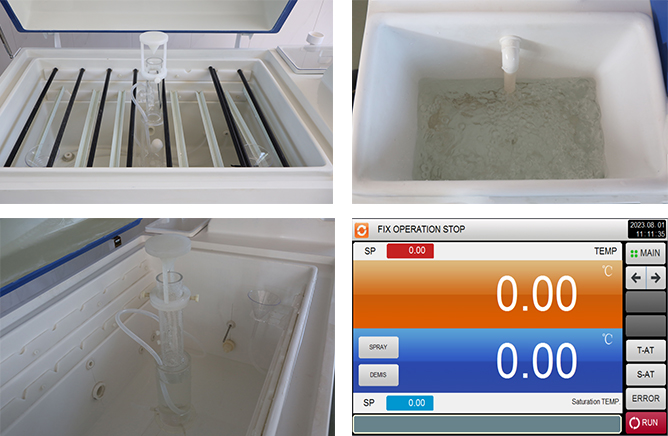

Even fog distribution via specialized nozzles and airflow systems.

Built from fiberglass-reinforced plastic—durable, acid- and salt-resistant.

Follows global standards: ASTM B117, ISO 9227, ASTM G85 (incl. Annex A1), SAE J2334, ISO 4611, ISO 7253, IEC 60068-2-11, DIN 50021, ASTM B368, and others .

Model | Internal (mm) | Volume (L) | Overall Size (mm) |

S-150 | 590 × 470 × 400 | 110 | 1460 × 760 × 1140 |

S-250 | 1000 × 640 × 500 | 320 | 1850 × 960 × 1350 |

S-750 | 1100 × 750 × 500 | 410 | 1950 × 1030 × 1350 |

S-010 | 1000 × 1300 × 600 | 780 | 2000 × 1300 × 1600 |

Temperature Range: Ambient to +60 °C | Fluctuation: ±0.5 °C | Deviation: ±2 °C

Humidity: 95%–98% RH | Salt Fog Deposition: 1–2 ml/80 cm²·h

Spray Modes: Continuous or Periodic | Controller: PID

Safety Features: Over-temp, over-current, water shortage, dry-combustion, earth-leakage protections | Material: Glass-fiber reinforced plastics

Automotive & Aerospace – Ensures components resist corrosion in harsh conditions.

Electronics – Protects sensitive parts from humidity and salt exposure.

Construction & Coatings – Validates paints, platings, and protective layers.

Research & Education – Ideal for universities and testing institutions.

Over 16 years of expertise in environmental test chambers.

Customization available – from size to control systems.

Global footprint – Trusted by manufacturers across Europe, Asia, and North America.

After-sales support – Professional engineers assist with installation, training, and service.

Contact LIB inquiry@libtestchamber.com today for a personalized quote and professional specification sheet. LIB team typically responds promptly—get the details you need to ensure your lab or production line is fitted with the industry’s most reliable salt spray testing cabinet.

Don’t wait—optimize your testing efficiency and accuracy with LIB’s advanced NSS/AASS/CASS salt spray cabinet.

In corrosion testing, using high-quality, versatile, and reliable equipment is non-negotiable. LIB’s salt spray cabinet meets this demand by delivering controlled, safe, and standard-compliant testing capabilities. Whether your lab focuses on standards compliance, material quality, or R&D, LIB’s range offers the ideal solution for accelerated and accurate corrosion assessment.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia