Today electronic products are at the heart of nearly every industry—automotive, aerospace, consumer electronics, telecommunications, energy, and medical devices. These products are expected to perform reliably under a vast range of environmental conditions, including exposure to extreme temperatures, rapid thermal transitions, and prolonged thermal stress.

To meet these expectations, manufacturers must validate their products through rigorous environmental testing—where the high low temperature test chamber plays a central role.

Unlike mechanical systems that may fail visibly or audibly, electronic systems often suffer silent degradation before failure. The internal circuitry, microchips, interconnects, and solder joints inside devices can all be significantly impacted by:

Thermal expansion and contraction: leading to fatigue and eventual cracking of solder joints or PCB traces.

Dielectric property shifts: causing signal interference or loss of function.

Condensation risks: especially when moving from cold to warm environments, leading to corrosion or short-circuiting.

Component drift: temperature can affect the values of resistors, capacitors, and sensors, leading to erratic behavior or malfunction.

Temperature extremes are among the most common environmental threats electronics face during their lifecycle—from manufacturing and shipping to deployment in real-world environments.

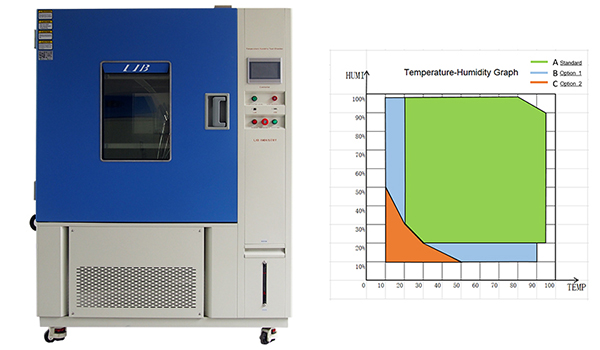

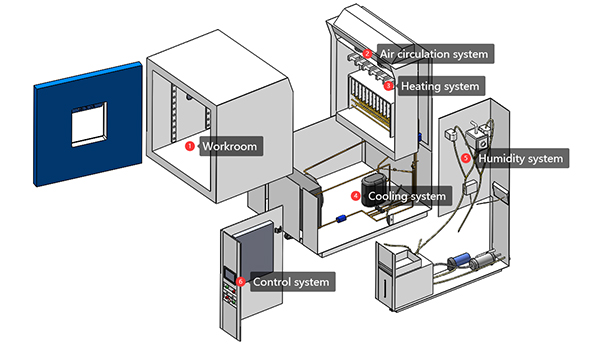

A high low temperature test chamber is designed to simulate extreme ambient conditions in a controlled and repeatable laboratory setting. With advanced programmable controllers, engineers can define specific temperature profiles, dwell times, ramp rates, and cyclic testing parameters to evaluate how a product responds over time and across conditions.

Wide temperature range: from -70°C,-40℃,-20℃ to +150°C, covering common international test standards.

Precise control: temperature accuracy ±0.5°C and uniformity within ±2.0°C to ensure reliable results.

Programmable cycling: simulate diurnal temperature shifts, start-stop cycles, and transportation conditions.

Data recording: monitor and log real-time data for post-analysis and report generation.

LIB high low temperature test chamber incorporate touch-screen PLC control systems, USB and Ethernet data interfaces, and robust insulation structures to deliver stable performance, even during long-term testing.

To better illustrate the practical importance of high low temperature testing, let’s examine a real-world case: the thermal validation of an automotive-grade rearview camera system.

Project Background:

An automotive supplier required verification of a CMOS-based rearview camera designed to operate across a wide temperature range—from harsh northern winters to desert heat. The system included a camera module, protective housing, PCB, and lens.

Temperature range: -40°C to +85°C

Ramp rate: 3°C/min

Cycle count: 100 cycles over 10 days

Evaluate the mechanical integrity of the lens and housing during expansion and contraction.

Observe image quality degradation at temperature extremes.

Check for internal condensation or fogging after rapid temperature shifts.

Monitor the electrical signal stability from the image sensor and circuit board.

Compliant with automotive standards ISO 16750-4 and AEC-Q100 standards

The test revealed intermittent image distortion below -30°C due to lens shrinkage and connector pin misalignment. The issue was resolved with material selection changes and retested successfully. Without this validation step, the defect would have led to widespread failure in cold climates and potential product recalls.

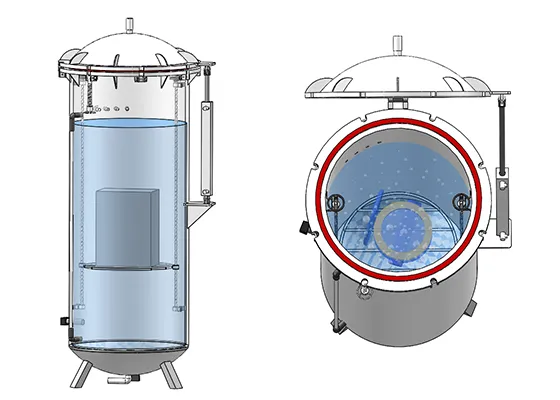

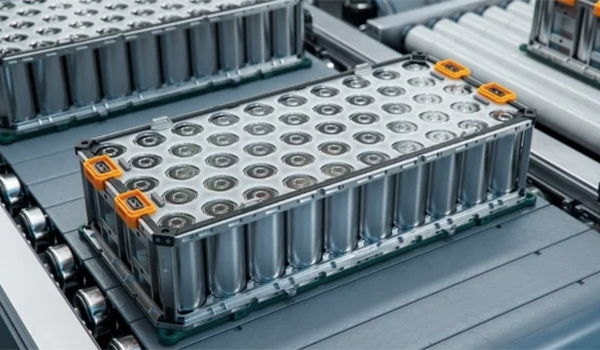

Lithium-ion batteries used in smartphones, drones, or EVs are highly sensitive to temperature. LIB chambers are used to simulate charging, discharging, and idle states under both cold (-20°C) and heat (+60°C) to evaluate thermal runaway risks and aging performance.LIB also offers specialized battery test chambers, equipped with an explosion-proof system.

Mobile phones, tablets, and wearable devices are often transported or used in extreme weather. Temperature cycle testing ensures that screens don’t crack, adhesives don’t delaminate, and touch sensors function correctly after repeated exposure to cold and hot environments.

Military-grade electronics must function from -55°C on the ground to +85°C in flight. LIB chambers support MIL-STD-810H and RTCA DO-160 compliant testing, simulating high-altitude low-pressure thermal scenarios combined with vibration.

Implantable or wearable medical electronics must undergo temperature testing to ensure stability of diagnostic readings or drug delivery performance in the human body or in varying ambient conditions.

High low temperature testing is often a mandatory part of regulatory compliance and certification. LIB’s chambers support a wide range of international testing standards, including:

IEC 60068-2-1 / IEC 60068-2-2: Environmental testing for low and high temperature resistance

MIL-STD-810H: U.S. military standard for equipment environmental testing

ISO 16750-4: Road vehicles – Environmental conditions and testing for electrical and electronic equipment

JEDEC JESD22-A104: Temperature cycling for semiconductor devices

LIB high low temperature test chambers are engineered to meet these standards reliably and repeatedly, making them suitable for certification testing labs and in-house QA departments alike.

As a leading manufacturer of environmental test chambers, LIB brings over 16 years of experience, precision engineering, and a customer-centric approach to every project

Reliable Performance

LIB environmental test chambers are built with high-efficiency refrigeration systems, corrosion-resistant SUS304 interiors, and industrial-grade components for long service life.

Tailored Solutions

From small benchtop chambers for R&D labs to walk-in test chambers for complete assemblies, LIB offers customizable sizes, temperature ranges, and control systems to meet any testing requirement.

Global Trust

LIB test equipment is trusted by electronics manufacturers, automotive OEMs, universities, research institutions, and aerospace companies across more than 60 countries.

Dedicated Support

We provide not just machines, but end-to-end service: test consulting, chamber design, installation, remote monitoring support, and calibration services.

Electronic products face a wide array of environmental challenges in their lifecycle. Without thorough validation under high and low temperature conditions, even the most advanced technology can fail unexpectedly in the field. A high low temperature test chamber ensures that these products can survive, operate, and thrive in real-world conditions.

Get in touch with us today to discuss your temperature testing needs or request a custom quote inquiry@libtestchamber.com.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia