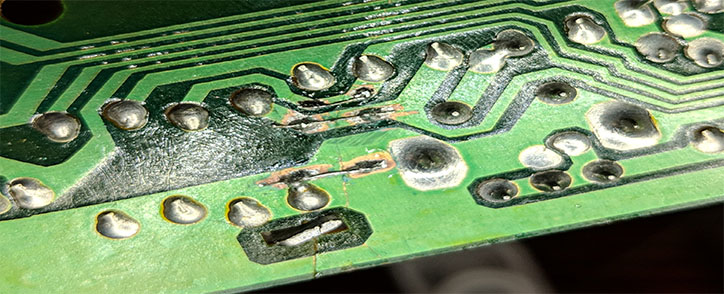

In today’s world of precision manufacturing, materials face one invisible enemy — thermal stress. Electronic components, including PCB circuit boards, can experience cracks, solder joint failures, or component detachment when subjected to rapid temperature changes.

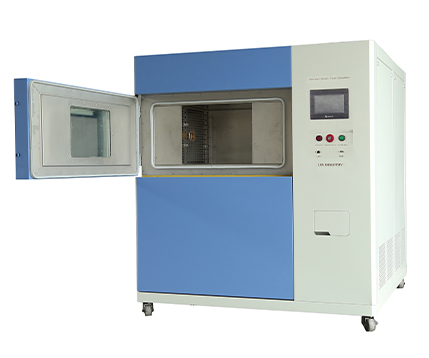

That’s why Thermal Shock Testing is essential. It simulates real-world thermal cycles, ensuring your products can withstand extreme environments. The thermal shock chamber is a specialized chamber that rapidly cycles between extreme high and low temperatures to test the resilience of materials to thermal stress.LIB Industry’s Thermal Shock Chamber provides the most reliable solution, performing temperature cycles from –70°C to +220°C in 3 seconds, identifying weaknesses before production deployment.

|  |

The LIB Industry Thermal Shock Chamber is designed for fast, accurate, and programmable temperature cycling. This Hot and Cold Shock Chamber exposes samples to extreme conditions within seconds.

Technical Specifications of Thermal Shock Chamber

Model | TS-162 | TS-340 | TS-500 | TS-1000 | |

Interior Volume (mm) | 22L | 72L | 211L | 505L | |

Loading Capacity | 20kg | 30kg | 50kg | 60kg | |

Pre-heat Room | Upper limit Temperature | +220℃ | |||

Heating Time | Ambient ~ + 200℃, within 30 minutes | ||||

Pre-cool Room | Lower limit Temperature | -75℃ | |||

Cooling time | Ambient ~ -70℃, within 30 minutes | ||||

Test Room | High Temperature Exposure Range | Ambient +20 ~ +200°C | |||

Low temperature Exposure Range | –65 ~ -5°C | ||||

Temperature Recovery Time | Within 5 minutes | ||||

Feedthrough port | Ø50 mm (sealed with rubber stopper) | ||||

Cooling method | Air-cooled / Water-cooled (≥500 L) | ||||

Standards | IEC 60068-2-14, MIL-STD-883, ISO 16750, JEDEC JESD22 | ||||

A common use is testing PCB circuit boards to ensure solder joints and components survive extreme thermal cycling.

Test Objective: Detect cracks, detachment, or degradation under rapid hot/cold cycles.

Testing Standard: IEC 60068-2-14 – Environmental testing for electrical and electronic components.

Test Conditions:

- Temperature cycle: –40°C ↔ +150°C

- Dwell time: 30 minutes per zone

- Number of cycles: 100

Test Result: After 100 cycles, PCB assemblies remained intact with no solder joint failure, confirming component reliability.

Tailor-Made for Your Application – Customization Options

LIB Industry understands that testing requirements vary. All Thermal Shock Chambers can be customized.

Customizable Feature | Available Options | Description |

Chamber Size | 50 L – 1000 L+ | Internal volumes adapted to sample size and test load. |

Cooling Method | Air-cooled / Water-cooled | Select based on capacity and lab environment. |

Thermal Shock Mode | Air-to-Air / Air-to-Liquid / Liquid-to-Liquid | Choose the mode for speed and material type. |

Safety Design | Explosion-proof models | For batteries or volatile material testing. |

Power Feedthrough | Ø50 mm cable port,quantity, location | Safe, sealed opening for powering test pieces. |

Selecting the correct configuration is essential:

Two-Zone (2TS): Direct hot-to-cold transfer, ideal for high-stress, rapid testing.

Three-Zone (3TS): Includes an ambient zone for standard-compliant thermal cycling.

|  |

Two-Zone Thermal Shock Chamber |

Selection Guide:

- High-stress or advanced reliability testing → 2TS

- Standard compliance and routine qualification → 3TS

LIB Industry offers 16+ years of environmental testing expertise, modern production facilities, and international service support.

Frequently Asked Questions (Thermal Shock Chamber FAQ)

Q1: How is power supplied to the test basket?

A: A 50 mm port with rubber plug allows safe cable passage while maintaining airtight sealing.

Q2: Does the test piece need to be fixed during testing?

A: No fixation needed. The pneumatic basket transfer system ensures stability.

Q3: Is an external air source required?

A: No, LIB units include a built-in pneumatic system.

Q4: Air-to-Air vs. Liquid-to-Liquid – which to choose?

A: Air-to-Air is for general electronics or plastic tests; Liquid-to-Liquid provides faster thermal transition for dense or metallic components.

Ready to test your materials against extreme temperature shocks?

Contact LIB Industry inquiry@libtestchamber.com with your test requirements. Within 1–3 hours, receive a tailored quotation and prompt proposal.

✔ 16+ years professional experience

✔ 3-year warranty & lifetime support

✔ Global service network for fast response

LIB Industry – Your trusted global partner for Thermal Shock Testing and Thermal Shock Test Machine solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia