Features and Benefits of UV Light Degradation Chamber

Multiple UV wavelength options

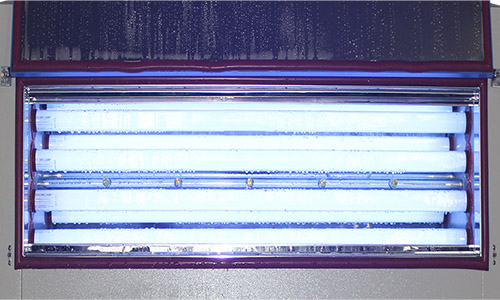

Selectable UVA (315–400 nm) and UVB (280–315 nm) lamps accurately simulate different sunlight conditions, allowing you to select the appropriate UV spectrum based on material type, test standard, and aging objective.

Integrated environmental control

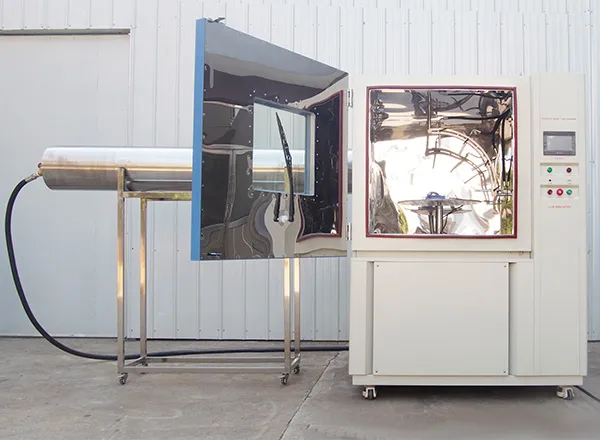

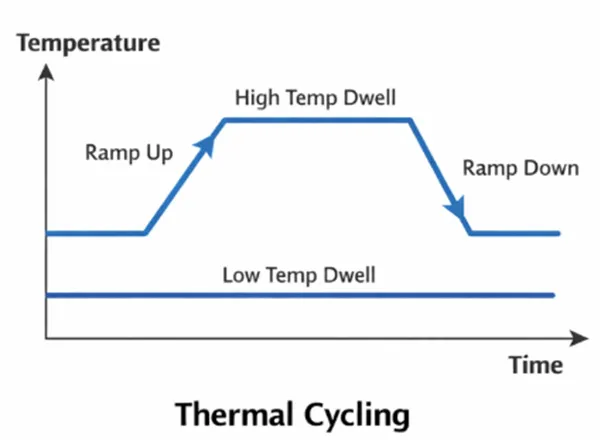

Precisely coordinated control of UV light, temperature, humidity, and water spray enables stable and repeatable weathering cycles, ensuring consistent test results across long-term and comparative studies.

Accelerated aging efficiency

High-intensity UV exposure significantly shortens aging cycles, helping you identify material degradation trends earlier, reduce validation time, and accelerate product development and qualification.

Flexible specimen configuration

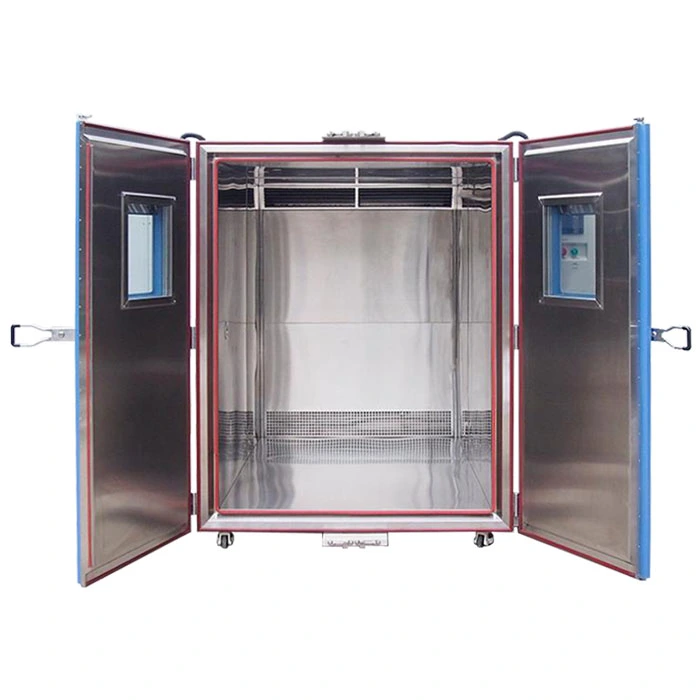

Customizable workroom sizes and specimen holders—including standard flat panels and tailored 3D fixtures—support a wide range of sample geometries, making the chamber suitable for both standard testing and real-product evaluation.

UV Light Degradation Chamber Specifications

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

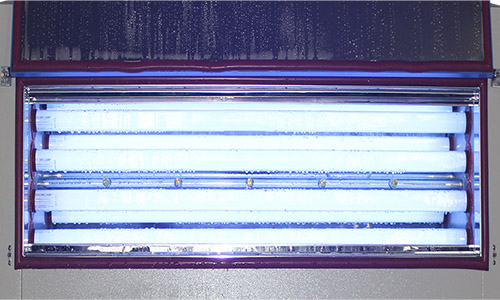

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

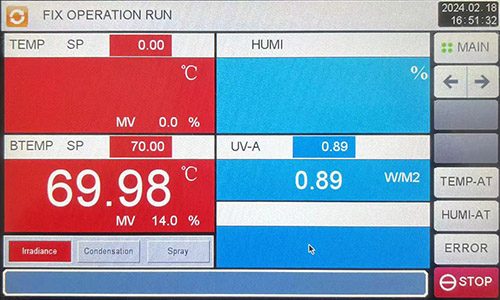

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

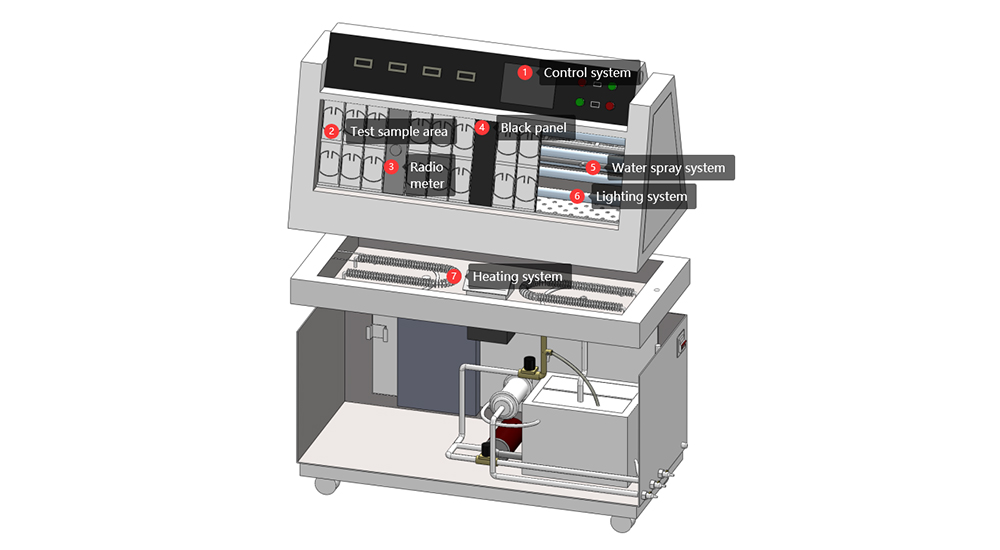

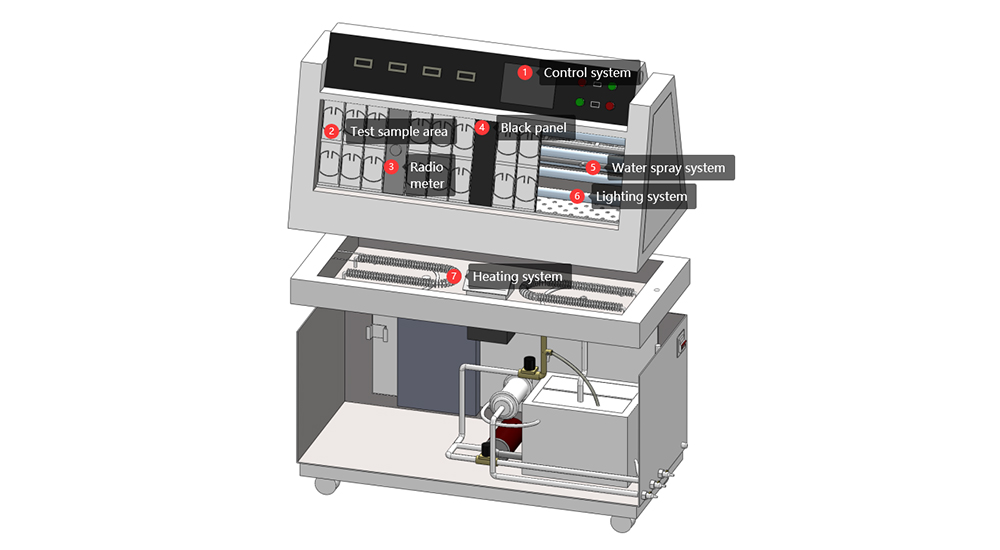

Configuration of UV Light Degradation Chamber

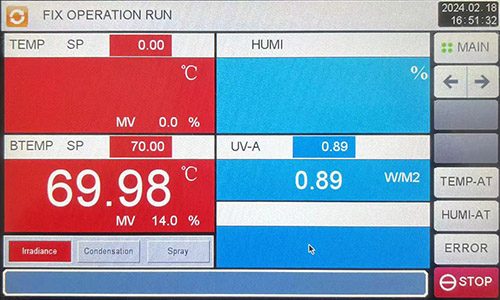

① Control system | The light, temperature, humidity, spray and other test conditions are precisely controlled and adjusted. With touch screen man-machine interface, the operation is intuitive and convenient, which can be used for parameter setting, data recording and viewing.

|  |

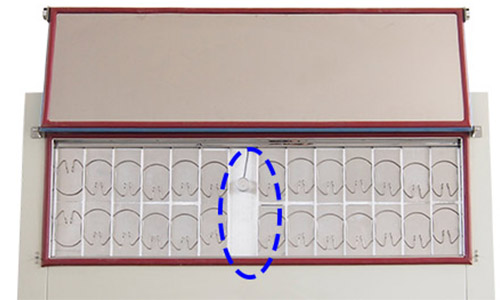

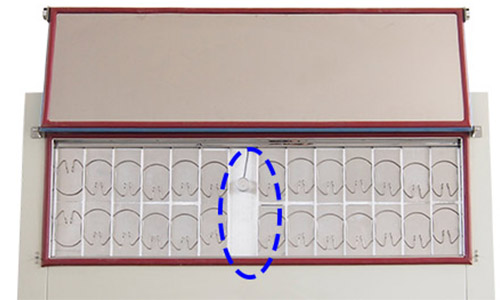

② Test sample area | Aluminum panels with rings,each specimen size is 75mm*150mm, can hold 52 pieces of specimens.

|  |

③ Radiometer | Measure the UV light degradation radiation intensity in the UV aging test chamber for calibration and adjustment. |  |

④ Black panel |

|  |

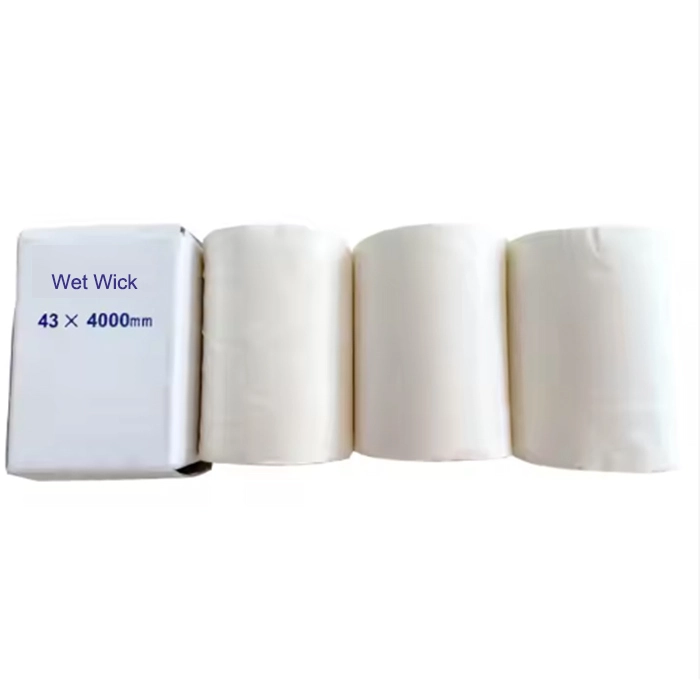

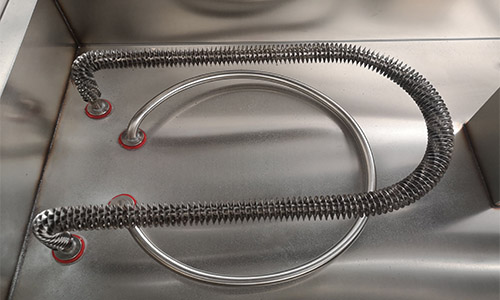

⑤ Water spray system | Simulate rain in the natural environment, reproduce the impact of rain on the product, and evaluate the weatherability of the material in complex environments such as dry and wet alternations. |  |

⑥ Lighting system | UVA-340 or UVB-313 lamps can simulate the ultraviolet part of sunlight, which is suitable for aging test of different materials. |  |

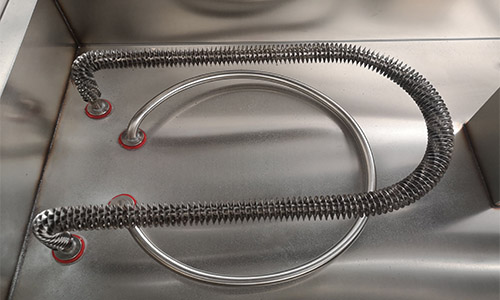

⑦ Heating system | Tank type heating, so that the temperature distribution inside the chamber is uniform. |  |

Frequently Asked Questions – UV Light Degradation Chamber

Q1: Which UV lamp should I choose for my material testing—UVA or UVB?

UVA lamps (such as UVA-340) closely simulate natural sunlight and are widely used for plastics, coatings, rubber, and automotive materials.

UVB lamps (UVB-313) deliver higher-energy radiation for accelerated or worst-case aging evaluations.

LIB industry can recommend the optimal lamp type and test configuration based on your material, standard, and target service life.

Q2: Can the test parameters be adjusted to match our internal or industry standards?

Yes. UV irradiance, temperature, humidity, and water spray cycles are fully programmable and repeatable.

The chamber supports test profiles in accordance with ASTM, ISO, JIS, as well as customized enterprise specifications.

Q3: How is long-term test accuracy and repeatability ensured?

The system includes a UV radiometer for irradiance monitoring and calibration, ensuring stable output during extended aging tests.

Combined with precise temperature and humidity control, this guarantees reliable and comparable test results over time.

Q4: Can the chamber handle non-standard samples or special test requirements?

Yes. LIB industry offers custom workroom sizes, 3D specimen holders, and fixture designs for irregular or oversized samples.

Share your sample dimensions or test goals with us, and we will propose a suitable configuration.

Q5: What support is included after installation?

Every UV light degradation chamber is supplied with a 3-year warranty, professional commissioning, and long-term technical support.

Remote assistance and fast-response service help minimize downtime and ensure continuous testing.

Looking to shorten your weathering test cycle or validate UV resistance more efficiently?

Contact LIB industry to inquiry@libtestchamber.com discuss your application and receive a tailored test solution.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia