Features and Benefits of IP56 Waterproof Chamber

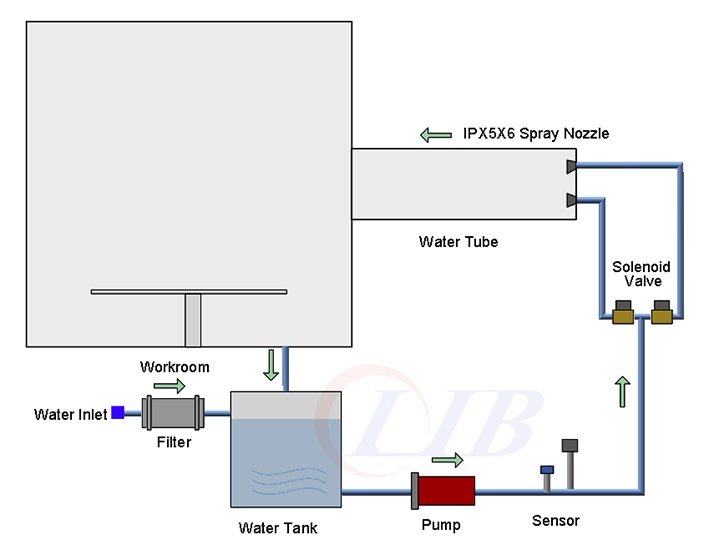

Nozzle with different aperture: IPX5 test chamber is equipped with nozzle with diameter of 6.3mm;IPX6 test is 12.5mm, which simulates the spray effect of different strengths.

Precise water flow control: IPX5 water flow is 12.5±0.625 (L/min); IPX6 water flow rate of 100±5 (L/min), through the flow meter can precisely adjust and control the water speed.

Specific spray distance: The distance from the nozzle to the sample is generally 2.5-3m, which can ensure that the water has the right impact and coverage area when it reaches the sample surface.

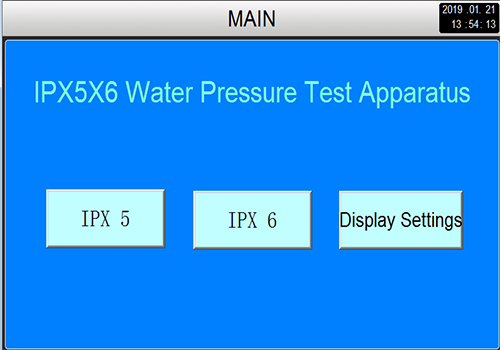

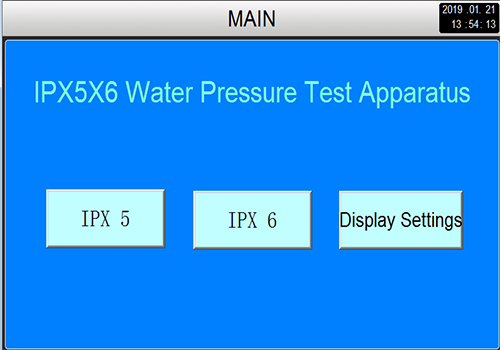

Control system function: water spraying parameters such as water spraying time, water spraying cycle, water flow intensity can be set on the touchable controller.

Rotatable sample table makes sure that specimen can get even water jetting impact, adjustable in height, equipped with waterproof single-phase power interface.

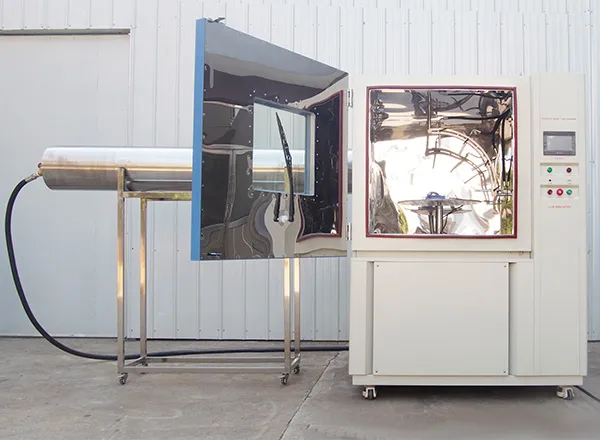

Specifications of IP56 Waterproof Chamber

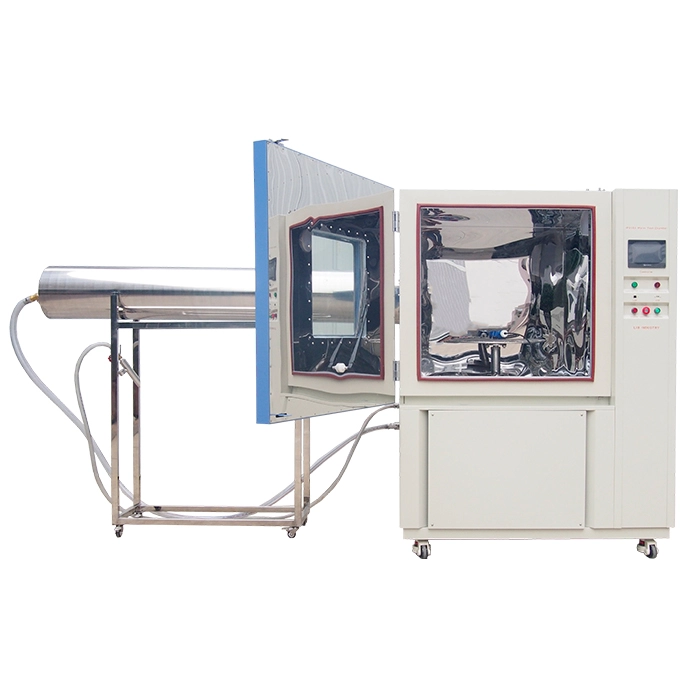

Workroom dimension (mm) | 800*800*800 D*W*H |

External dimension (mm) | 950*3150*1800 D*W*H |

Interior Volume (L) | 510 |

Diameter of Turntable (mm) | 600 |

Turntable loads | 20kgs Max |

Parameter | Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3mm |

Internal Diameter of IPX6 Nozzle | 12.5mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

Build-in Water Tank(mm) | 370*375*950 |

Environmental Conditional | 5℃~+35 ℃ ≤85% RH |

Standard | IEC 60529, ISO20653 |

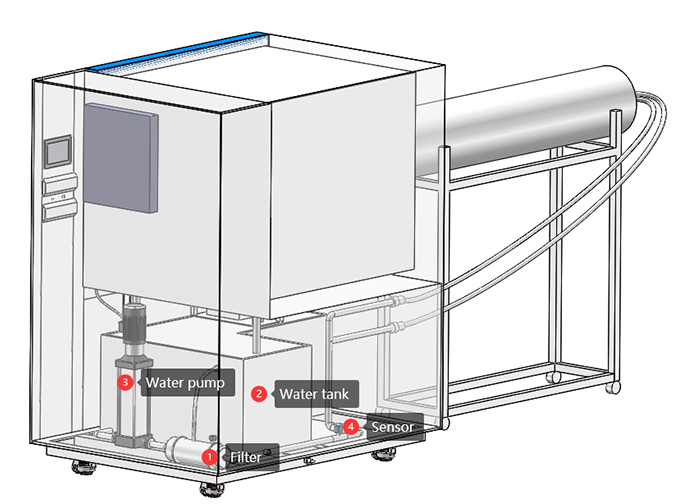

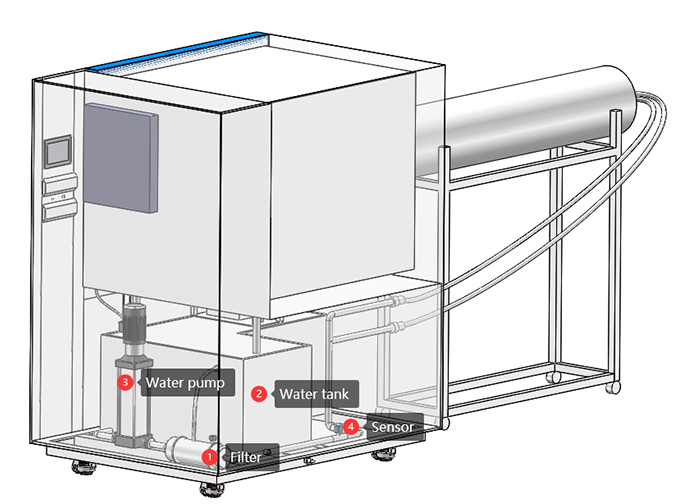

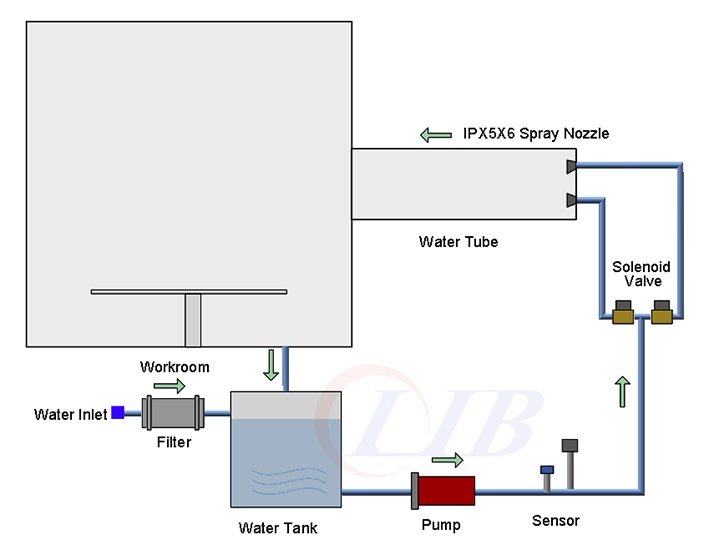

Configuration of IP56 Waterproof Chamber

①Filter

Filter impurities in 0.03mm particles, avoid nozzle blockage, ensure water spraying uniformity and stable flow, and protect equipment.

②Water tank

Water storage to provide a sufficient water source for the test and balance the water pressure changes so that the water can be recycled.

③Water pump

Provide power to extract water from the tank, and provide sufficient pressure, and can control the flow and pressure of water.

④Sensor

Monitor the operating status of the equipment and feed back the control signal: the monitored information is fed back to the control system.

A series of water pipes are arranged in LIB Industry IP56 waterproof chamber to form a water circulation system, which greatly reduces the water consumption.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia