When it comes to testing waterproof performance under the most extreme industrial conditions, the nozzle design inside your test chamber can make or break the accuracy of your results. For IPX6K and IPX9K testing, which involve high-pressure, high-temperature water jets, the double-nozzle spray system is not just an add-on—it’s the centerpiece of performance.

In this article, we focus specifically on the double-nozzle system: how it works, how it enables compliance with both IPX6K and IPX9K standards, and why IP69K test chamber is essential for testing in the automotive, outdoor electronics, and food-grade equipment sectors.

Before diving into the system, let’s clarify the difference between IPX6K and IPX9K—both defined in ISO 20653 for road vehicles and similar harsh applications:

Rating | Pressure | Temperature | Distance | Application |

IPX6K | 75–100 bar | Ambient | 2.5–3 m | Road spray, car wash |

IPX9K | 80–100 bar | 80±5°C | 100–150 mm | Steam cleaning, food-grade sanitation |

To pass both tests, the test system needs to simulate two very different spray profiles: a distant, broad spray (IPX6K) and a close-up, concentrated hot water jet (IPX9K).The double-nozzle system solves this dual requirement in one compact configuration.

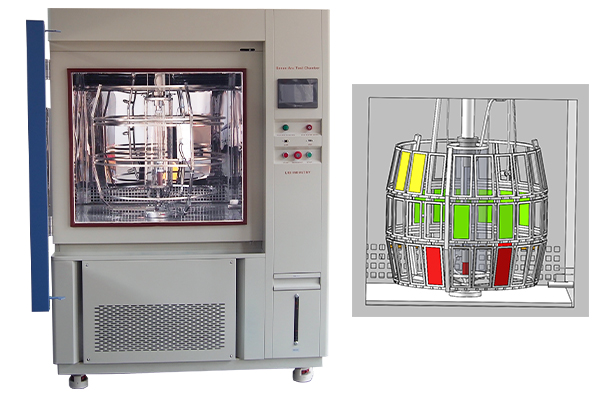

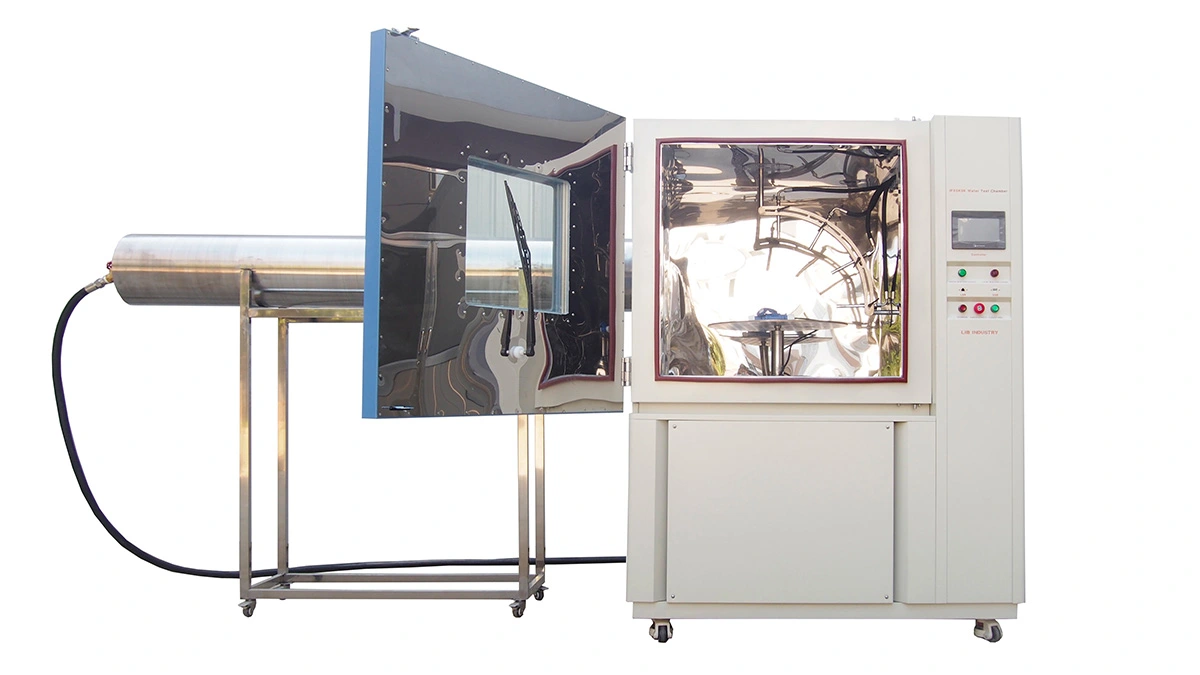

The LIB IPX6K/IPX9K test chamber is purpose-built to execute both high-pressure water ingress tests in full compliance with ISO 20653, IEC 60529, and automotive OEM standards.

Integrated System Features:

Double-Nozzle Configuration | ▪ Fixed long-range nozzle for IPX6K horizontal water jet testing (2.5–3.0 m distance) |

|

High-Pressure + Heating System | ▪ Adjustable output pressure up to 100 bar |

|

Automated Control Platform | ▪ Touchscreen interface with pre-loaded IPX6K & IPX9K test programs |

|

Chamber Workroom Construction | ▪ 100% stainless steel SUS304 workroom interior |

|

This single IP69K test chamber, equipped with a fully integrated dual-nozzle system, enables seamless transition between IPX6K and IPX9K modes, reducing changeover time and boosting throughput.

1. One System, Two Ratings

Rather than using separate setups, a dual-nozzle design seamlessly accommodates both IPX6K and IPX9K requirements—saving time, space, and equipment costs.

2. No Repositioning or Manual Adjustments

Chambers without a dual-nozzle system often require manual repositioning of the spray head or switching components between tests. LIB’s system is automated, programmable, and efficient.

3. Consistent Angular Accuracy

For IPX9K, spray angle consistency is vital. With a motorized rotating head and fixed-angle nozzles, the double-nozzle configuration maintains precise, repeatable testing.

4. Accelerated Testing Workflow

Run both test standards in one sequence with a pre-set test program. Combined testing helps reduce total cycle time by up to 30% compared to single-mode systems.

Here’s how real manufacturers benefit from a IP69K test chamber with a double-nozzle system:

Automotive Electronics: Tier-1 suppliers test radar sensors, ECUs, and connectors using IPX6K for road splash resistance and IPX9K for pressure wash zones (e.g., engine bay, undercarriage).

Food-Grade Machinery: Manufacturers of control panels, HMI touchscreens, and stainless cabinets need IPX9K to ensure components withstand hot high-pressure sanitation.

Smart Outdoor Devices: 5G base stations, smart parking systems, and roadside monitors require both ratings for protection against rain (IPX6K) and steam cleaning (IPX9K).

If you need to ensure your products meet the highest ingress protection standards, don’t settle for makeshift setups or incomplete testing.LIB’s IP69K test chamber with dual-nozzle system delivers certified precision, simplified operation, and reliable results—all in one platform.Contact LIB today inquiry@libtestchamber.com to get a quote or schedule a live demo.

Let us help you validate your product.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia