IEC 61215 is one of the most widely recognized international standards for the design qualification and type approval of crystalline silicon photovoltaic (PV) modules. Rather than focusing on a single performance metric, the standard evaluates whether a PV module can maintain electrical safety, power output, and structural integrity after prolonged exposure to environmental and operational stresses.

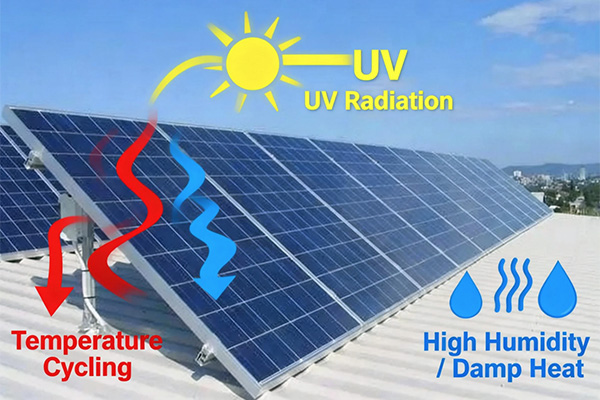

Field failures of PV modules rarely result from one extreme event. Instead, they are usually caused by cumulative environmental aging, such as repeated temperature fluctuations, long-term humidity exposure, and ultraviolet (UV) radiation. For this reason, environmental and climatic tests form the backbone of IEC 61215 qualification.

This article explains the structure of IEC 61215, highlights the most critical environmental reliability tests, and shows how LIB industry supports these tests through temperature humidity test chambers, PV environmental test chambers with fast temperature ramp rates, and UV test chambers—while also offering complete IEC 61215 laboratory solutions.

IEC 61215 organizes PV module qualification into several major test categories, each targeting a different failure mechanism:

Electrical performance and safety tests

Verification of power output, insulation, and electrical safety under defined conditions.

Mechanical stress tests

Evaluation of resistance to wind, snow, and impact loads.

Environmental aging tests

Simulation of long-term exposure to temperature cycling, humidity, and UV radiation.

Damp heat and humidity freeze tests

Accelerated assessment of moisture-related degradation and material fatigue.

Special and reference tests

Including bypass diode, hot-spot endurance, and PID-related evaluations.

Among these categories, environmental aging tests are the most time-consuming and failure-sensitive, and they rely heavily on precise climatic and radiation simulation.

Environmental aging tests are designed to reproduce years of outdoor exposure within a controlled laboratory timeframe. They directly address the most common degradation mechanisms observed in PV modules, including solder joint fatigue, encapsulant aging, moisture ingress, corrosion, and UV-induced material breakdown.

Because these tests apply continuous or cyclic stress over hundreds or thousands of hours, the stability, uniformity, and long-term reliability of test equipment are critical to achieving valid and repeatable results.

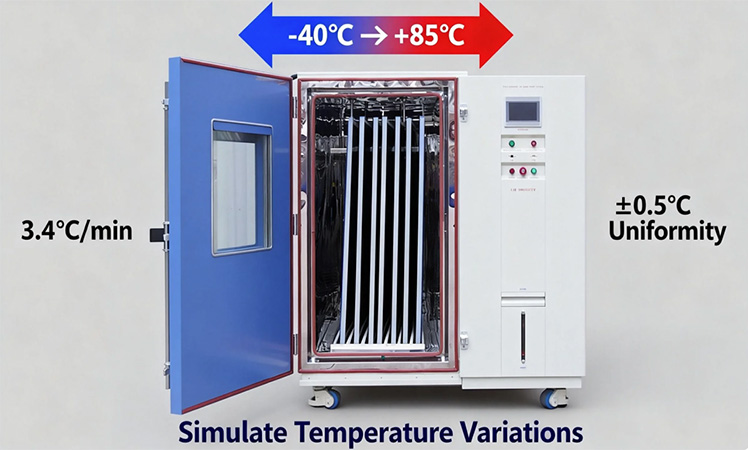

The thermal cycling test evaluates a PV module’s ability to withstand repeated temperature changes caused by daily and seasonal variations.

Typical test conditions

Temperature range from –40 °C to +85 °C, repeated for up to 200 cycles.

Failure mechanisms assessed

Solder joint cracking, interconnection fatigue, cell microcracks, and material expansion mismatch.

LIB industry solution – PV Environmental Test Chambers

LIB industry provides PV environmental test chambers specifically designed for large-format photovoltaic modules and long-duration thermal cycling programs required by IEC 61215.

Key advantages include:

Fast temperature change rate up to 3.4 °C/min, enabling efficient completion of 200-cycle thermal tests without compromising control accuracy

-60℃ ~ +100 ℃ Wide temperature range covering IEC 61215 requirements with stable performance at extreme low and high temperatures

High temperature uniformity across large PV modules, minimizing edge-to-center deviation during rapid cycling

Full-size PV module testing, allowing the entire panel to be tested as a single unit for realistic stress simulation

Customizable sample capacity, supporting multiple PV modules per test

Adjustable sample racks, accommodating varying module dimensions and thicknesses to meet different laboratory or production requirements

These features ensure reliable thermal stress simulation while reducing total test time and improving laboratory throughput.

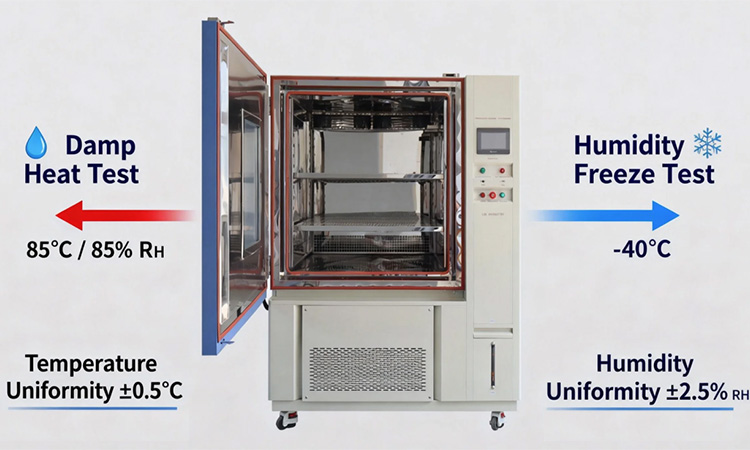

These tests evaluate PV modules’ ability to withstand moisture-related aging and freeze–thaw stress caused by repeated condensation, freezing, and thawing cycles.

Typical test conditions

Damp Heat: 85 °C / 85 % RH for 1000 hours

Humidity Freeze: High humidity exposure followed by rapid cooling to sub-zero temperatures, repeated for multiple cycles

Failure mechanisms assessed

Encapsulant hydrolysis, corrosion of conductive parts, insulation degradation, delamination, seal failure, and mechanical stress from expansion/contraction

LIB industry solution – Temperature Humidity Test Chambers

LIB industry provides temperature humidity test chambers capable of performing both Damp Heat and Humidity Freeze tests for full-size photovoltaic modules, ensuring comprehensive moisture and thermal stress evaluation.

Key advantages include:

Precise control at 85 °C / 85 % RH for damp heat testing, with minimal humidity drift during long-duration operation

Stable low-temperature performance for humidity freeze cycles, ensuring accurate and repeatable freeze–thaw simulations

Uniform temperature ±0.5 °C and humidity ±2.5 % RH, guaranteeing consistent exposure across large PV module surfaces

Durable, corrosion-resistant SUS304 chamber interior, suitable for prolonged high-humidity testing

Smooth transitions between temperature phases, minimizing overshoot and ensuring reliable cycling

Customizable sample capacity, supporting multiple modules per test

These temperature humidity chambers provide a versatile and reliable solution for performing both tests efficiently, accurately, and at full module scale, replicating real-world environmental stresses.

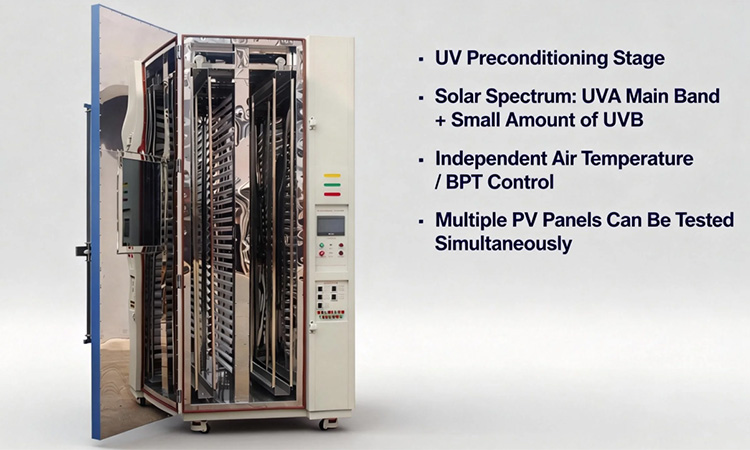

UV preconditioning exposes PV modules to controlled ultraviolet radiation before other environmental tests.

Objective

To assess UV-induced aging of encapsulants, backsheet materials, and surface coatings.

Why it matters

UV degradation often accelerates subsequent moisture and thermal aging mechanisms, influencing overall test outcomes.

LIB industry solution – UV Preconditioning Test Chamber

LIB industry UV Preconditioning Test Chambers are designed to provide controlled and uniform ultraviolet exposure for PV module preconditioning.

Key Advantages – UV Preconditioning Test Chamber for Solar Panels

Solar-relevant UV spectrum with upgraded lamp configuration

The latest UVP series uses all-UVA fluorescent lamps with a small, controlled proportion of UVB, precisely meeting IEC 61215 preconditioning requirements while providing more uniform irradiance across the entire PV module surface.

Stable and energy-based UV dose control

Cumulative energy targets in the 280–320 nm and 320–400 nm bands ensure consistent material stress and repeatable aging results across multiple test batches.

Independent thermal and Black Panel Temperature (BPT) regulation

Chamber air temperature (ambient to 90 °C ±2 °C) and BPT (35–80 °C) are controlled independently, eliminating thermal coupling and ensuring pure UV-driven aging mechanisms are accurately applied.

Full-size PV module compatibility

Vertical specimen holders accommodate large solar panels, allowing multiple modules to be tested simultaneously with stable exposure geometry and no irradiance shadowing.

Optimized for IEC 61215 test sequences

Designed as a UV preconditioning stage before damp heat, thermal cycling, or combined climatic tests, enabling seamless integration into complete photovoltaic qualification workflows.

Reliable, long-term operation

Stable irradiance output, uniform radiation distribution, and durable chamber construction ensure consistent performance over extended test periods, supporting accurate and repeatable preconditioning results.

By delivering consistent UV preconditioning, these systems help ensure accurate and repeatable downstream environmental test results.

Beyond individual environmental test chambers, LIB industry supports the design and delivery of complete IEC 61215 test laboratories, tailored to specific module sizes, throughput requirements, and certification strategies.

In addition to environmental aging tests, IEC 61215 includes several electrical, thermal, and functional verifications. These tests are essential for overall qualification but are typically short-term or event-based and rely on dedicated electrical or mechanical test systems rather than climatic simulation equipment.

Hot-Spot Endurance Test

Evaluates resistance to localized overheating caused by partial shading or cell mismatch.

Bypass Diode Thermal Test

Verifies the thermal stability of bypass diodes under reverse-bias conditions.

Insulation, dielectric, and wet leakage tests

Ensure electrical safety and insulation integrity, especially under humid conditions.

Potential-Induced Degradation (PID) test (reference)

Commonly performed according to IEC TS 62804-1 to assess power loss risk under high-voltage stress.

These tests typically complement environmental aging evaluations and are conducted before and after climatic testing to confirm compliance with IEC acceptance criteria.

A standard IEC 61215 environmental testing sequence usually includes:

Baseline electrical performance measurement

UV preconditioning

Damp heat exposure

Thermal cycling and/or humidity freeze testing

Intermediate inspections and measurements

Final electrical and safety verification

Environmental tests are not isolated procedures; their combined effect provides a comprehensive view of long-term module reliability.

While individual test chambers address specific IEC 61215 requirements, full compliance often requires a system-level laboratory approach.

LIB industry supports customers at multiple levels:

Standalone temperature humidity test chambers

PV environmental test chambers with fast temperature ramp capability

UV test chambers for preconditioning and aging

Customized planning and integration of complete IEC 61215 test laboratories

This flexibility allows manufacturers, laboratories, and research institutions to scale from targeted environmental testing to full qualification capability.

With specialized environmental test chambers and the ability to deliver complete IEC 61215 laboratory solutions, LIB industry helps PV manufacturers turn international standards into reliable testing processes—and long-term product confidence.

Contact LIB industry inquiry@libtestchamber.com to discuss customized IEC 61215 environmental testing solutions for your PV modules.

3-Year Warranty | Lifetime Technical Support | Rapid Engineering Response

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia